When pouring a seal, use a fibre dam to assure proper formation of the seal. Seals should never be poured at temperatures below freezing.

The jacket and shielding of the cable should be stripped back to permit the seal to form around the individual wires. This will prevent air, gas and water leakage through the inside of the shield and into the enclosure.

It is recommended that

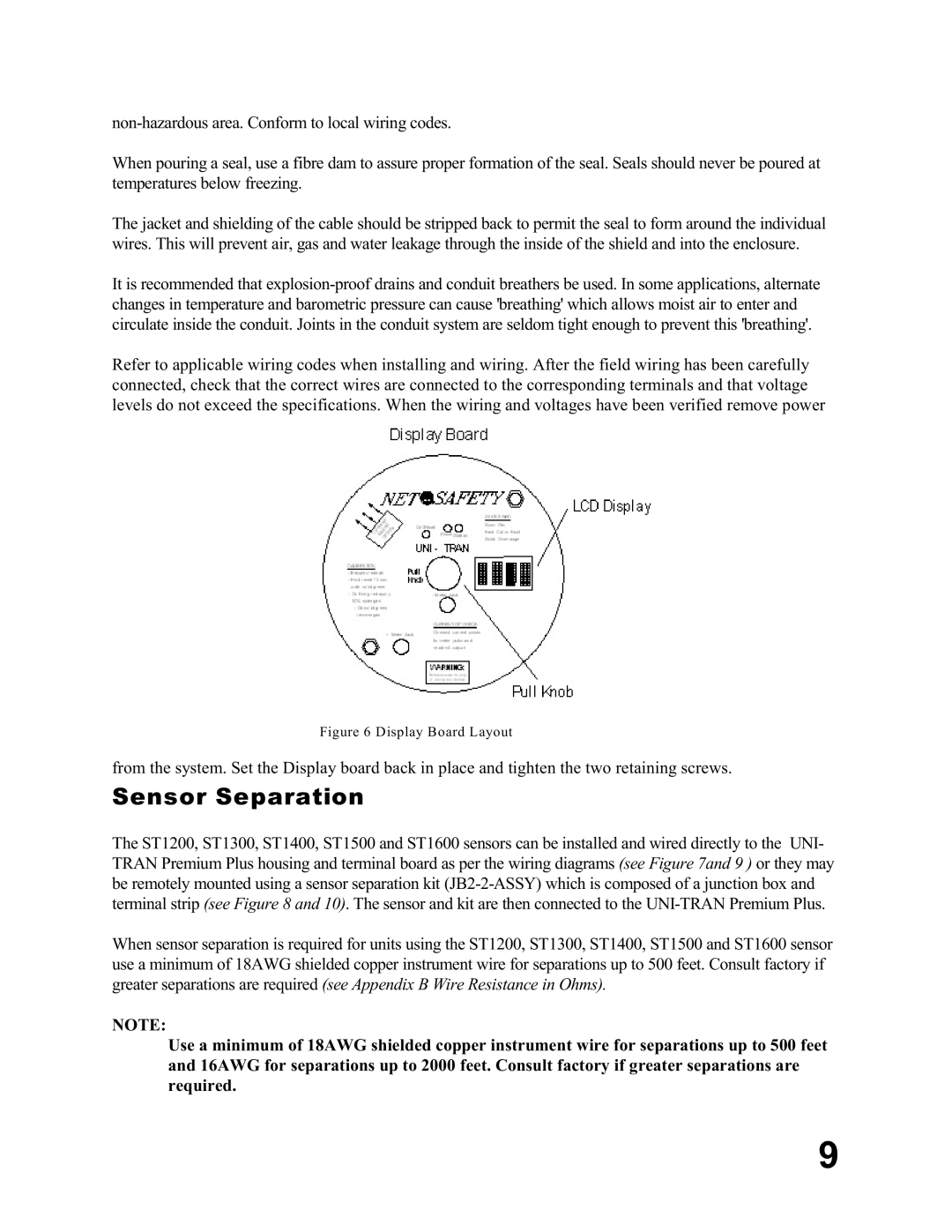

Refer to applicable wiring codes when installing and wiring. After the field wiring has been carefully connected, check that the correct wires are connected to the corresponding terminals and that voltage levels do not exceed the specifications. When the wiring and voltages have been verified remove power

Figure 6 Display Board Layout

from the system. Set the Display board back in place and tighten the two retaining screws.

Sensor Separation

The ST1200, ST1300, ST1400, ST1500 and ST1600 sensors can be installed and wired directly to the UNI- TRAN Premium Plus housing and terminal board as per the wiring diagrams (see Figure 7and 9 ) or they may be remotely mounted using a sensor separation kit

When sensor separation is required for units using the ST1200, ST1300, ST1400, ST1500 and ST1600 sensor use a minimum of 18AWG shielded copper instrument wire for separations up to 500 feet. Consult factory if greater separations are required (see Appendix B Wire Resistance in Ohms).

NOTE:

Use a minimum of 18AWG shielded copper instrument wire for separations up to 500 feet and 16AWG for separations up to 2000 feet. Consult factory if greater separations are required.

9