Adjusting your Hopper Lid Latch

The seals around the top of the pellet hopper are important to safe an efficient operation of the unit. The latch installed on these units is designed to pull the hopper lid tight against this seal. Over the course of operation as these seals “wear in” and compress, the tension of the latch should be tested periodically, and adjusted if necessary.

To adjust the lid latch, the following tools will be needed; two ½ inch wrenches, or a ½ inch wrench and a ½ inch socket.

In order to adjust the latch, first open the hopper lid and then lock the latch in its closed position. Then take the ½ inch wrench and loosen the nut closest to the latch. This nut is then adjusted closer to the lid itself to tighten the latch. After adjusting this nut to the desired location, hold this nut in place with the ½ inch wrench, the tighten down the holding nut on the end of the latch shaft with the ½ inch socket or second wrench to hold the latching assembly in place

After tightening the latch, test the latch for proper tension by locking the lid down and lifting each front corner of the lid. The lid should be firmly held down by the latch. Repeat the same procedure if the latch is still not tight enough.

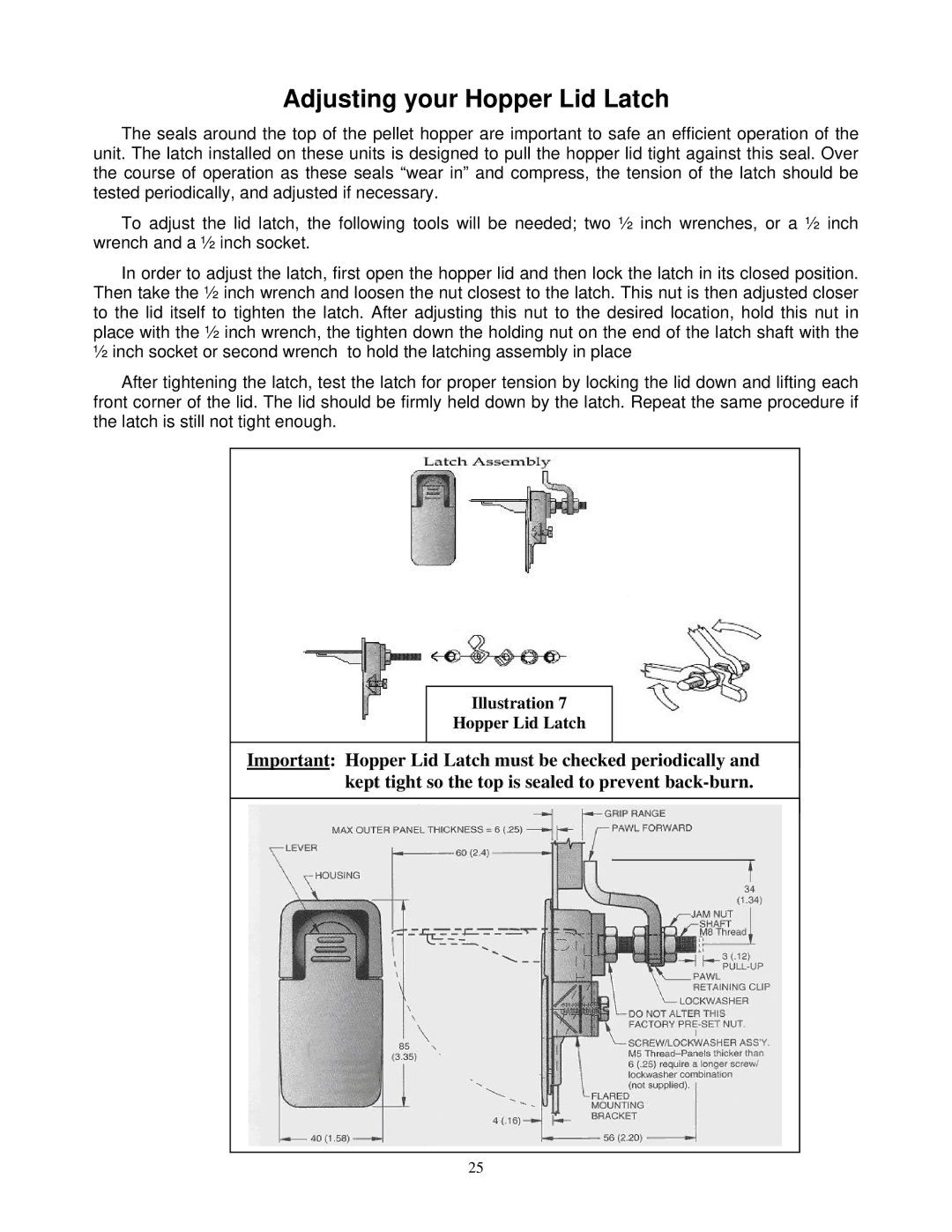

Illustration 7

Hopper Lid Latch

Important: Hopper Lid Latch must be checked periodically and kept tight so the top is sealed to prevent

25