Sawgrass Technologies, Inc.SubliJet IQ® Getting Started Guide for the EPSON Stylus Photo 1280

Heat Transfer Instructions

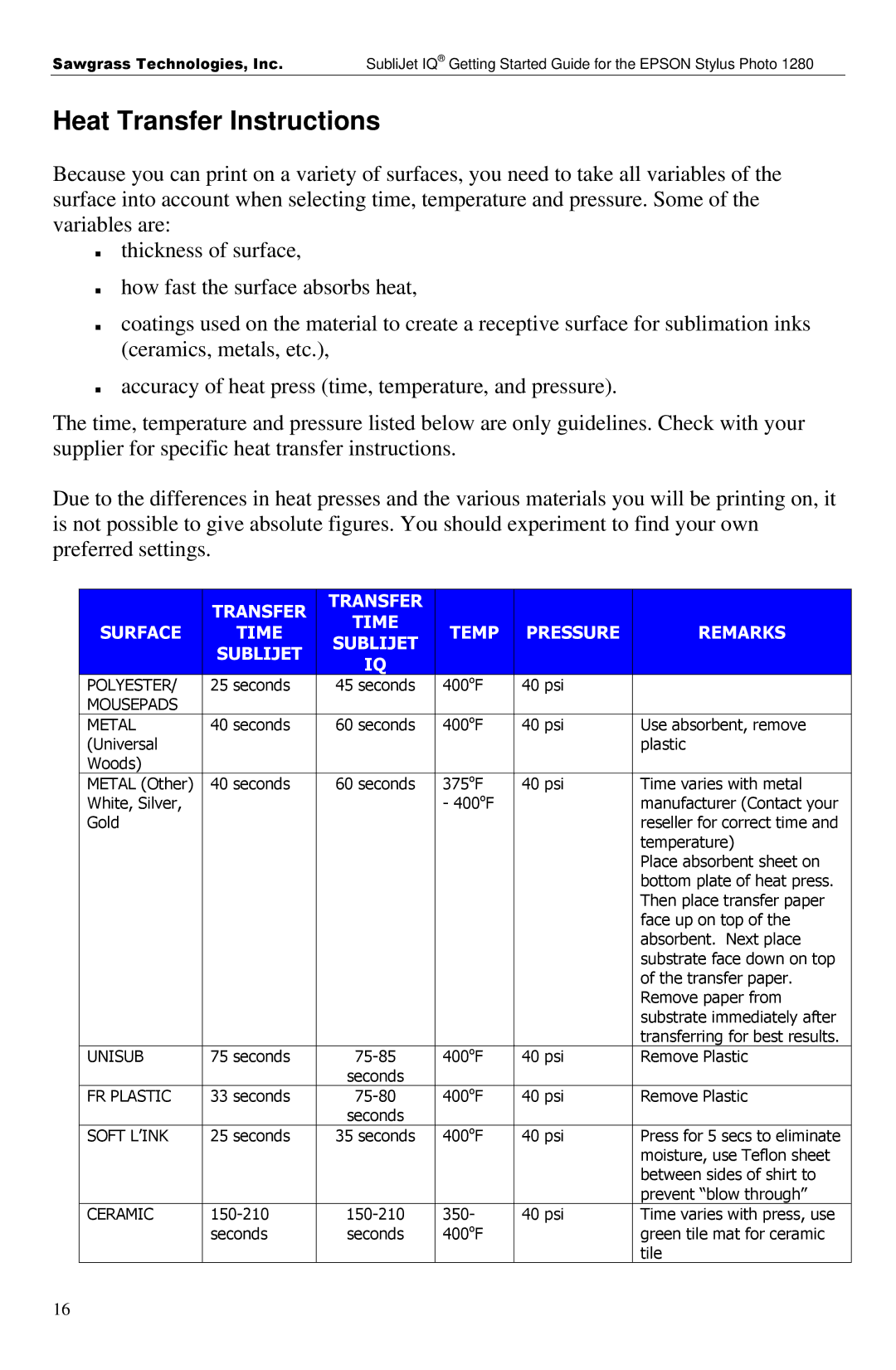

Because you can print on a variety of surfaces, you need to take all variables of the surface into account when selecting time, temperature and pressure. Some of the variables are:

nthickness of surface,

n

n

how fast the surface absorbs heat,

coatings used on the material to create a receptive surface for sublimation inks (ceramics, metals, etc.),

naccuracy of heat press (time, temperature, and pressure).

The time, temperature and pressure listed below are only guidelines. Check with your supplier for specific heat transfer instructions.

Due to the differences in heat presses and the various materials you will be printing on, it is not possible to give absolute figures. You should experiment to find your own preferred settings.

|

|

|

| TRANSFER |

|

| TRANSFER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TIME |

|

|

|

|

|

|

|

|

|

| |

| SURFACE |

|

| TIME |

|

|

|

| TEMP |

|

| PRESSURE |

|

| REMARKS |

| |

|

|

|

|

| SUBLIJET |

|

|

|

|

|

|

| |||||

|

|

|

| SUBLIJET |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

| IQ |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| POLYESTER/ |

|

| 25 seconds |

|

| 45 seconds |

|

| 400oF |

|

| 40 psi |

|

|

|

|

| MOUSEPADS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| METAL |

|

| 40 seconds |

|

| 60 seconds |

|

| 400oF |

|

| 40 psi |

|

| Use absorbent, remove |

|

| (Universal |

|

|

|

|

|

|

|

|

|

|

|

|

|

| plastic |

|

| Woods) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| METAL (Other) |

|

| 40 seconds |

|

| 60 seconds |

|

| 375oF |

|

| 40 psi |

|

| Time varies with metal |

|

| White, Silver, |

|

|

|

|

|

|

|

| - 400oF |

|

|

|

|

| manufacturer (Contact your |

|

| Gold |

|

|

|

|

|

|

|

|

|

|

|

|

|

| reseller for correct time and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| temperature) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Place absorbent sheet on |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| bottom plate of heat press. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Then place transfer paper |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| face up on top of the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| absorbent. Next place |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| substrate face down on top |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| of the transfer paper. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Remove paper from |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| substrate immediately after |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| transferring for best results. |

|

| UNISUB |

|

| 75 seconds |

|

|

| 400oF |

|

| 40 psi |

|

| Remove Plastic |

| ||

|

|

|

|

|

|

| seconds |

|

|

|

|

|

|

|

|

|

|

| FR PLASTIC |

|

| 33 seconds |

|

|

| 400oF |

|

| 40 psi |

|

| Remove Plastic |

| ||

|

|

|

|

|

|

| seconds |

|

|

|

|

|

|

|

|

|

|

| SOFT L’INK |

|

| 25 seconds |

|

| 35 seconds |

|

| 400oF |

|

| 40 psi |

|

| Press for 5 secs to eliminate |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| moisture, use Teflon sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| between sides of shirt to |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| prevent “blow through” |

|

| CERAMIC |

|

|

| 350- |

|

| 40 psi |

|

| Time varies with press, use |

| |||||

|

|

|

| seconds |

|

| seconds |

|

| 400oF |

|

|

|

|

| green tile mat for ceramic |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| tile |

|

16