APPENDIX C

BONDING & GROUNDING OF BATTERY RACK

INTRODUCTION

1. To insure personnel safety, and equipment protection, operation, and reliability, the battery rack should be connected to the Common Bonding Network (CBN).

2. Electrical continuity between modules is provided through the use of serrated hardware. Testing has shown that standard sys- tems are compliant with the

GROUNDING KIT INSTALLATION (OPTIONAL)

1. Each kit consists of the following components:

(2) #6 AWG, 12 in. 90°C cables

(4) “C” shaped beam clamps

(4)

(4)

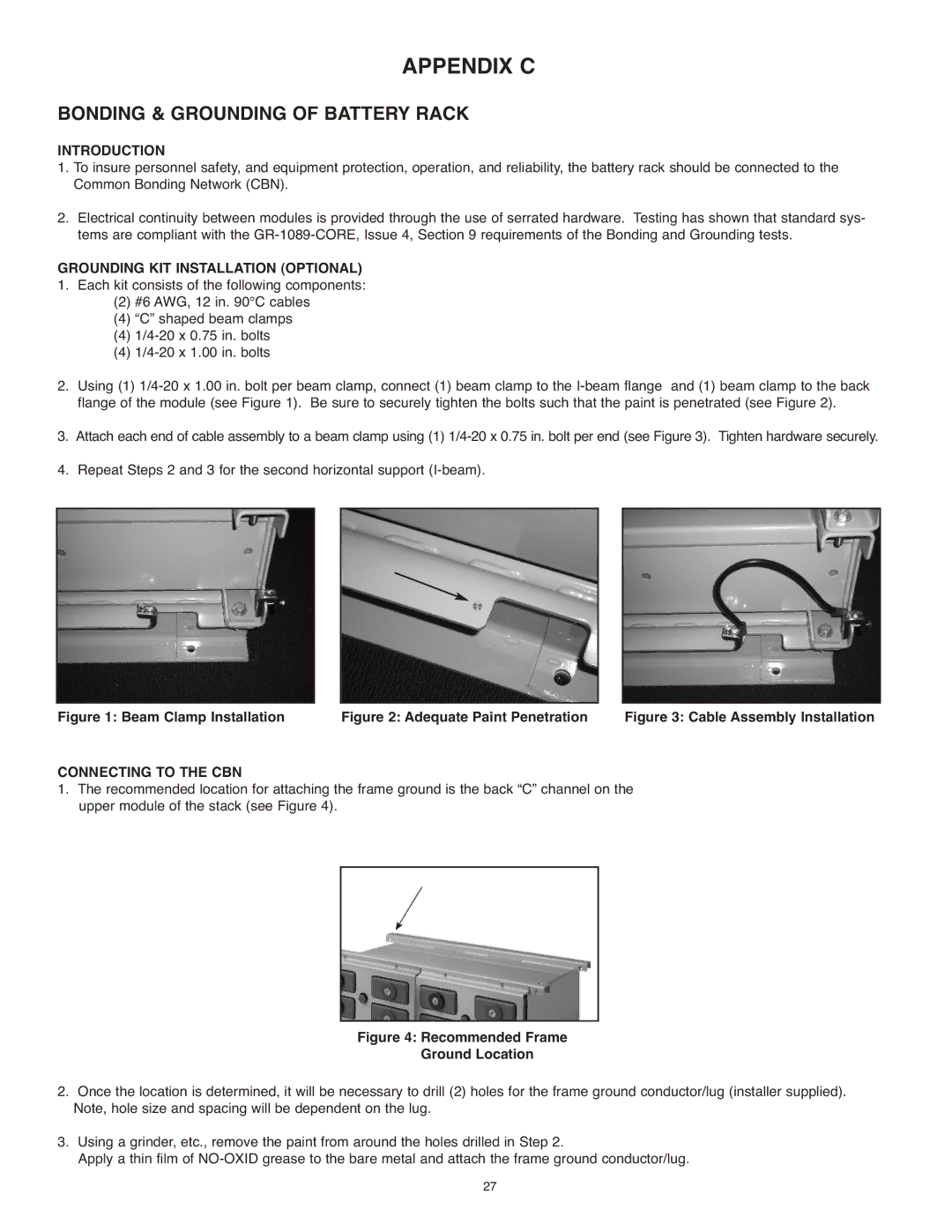

2. Using (1)

3. Attach each end of cable assembly to a beam clamp using (1)

Figure 1: Beam Clamp Installation

Figure 2: Adequate Paint Penetration

Figure 3: Cable Assembly Installation

CONNECTING TO THE CBN

1. The recommended location for attaching the frame ground is the back “C” channel on the upper module of the stack (see Figure 4).

Figure 4: Recommended Frame

Ground Location

2. Once the location is determined, it will be necessary to drill (2) holes for the frame ground conductor/lug (installer supplied). Note, hole size and spacing will be dependent on the lug.

3. Using a grinder, etc., remove the paint from around the holes drilled in Step 2.

Apply a thin film of