Maintenance

4.Check the condition of the inner element. Replace whenever it appears dirty, typically every other time the paper element is replaced. Clean the base around the inner element before removing, so dirt does not get into the engine.

5.Do Not wash or use pressurized air to clean paper element or inner element.

6.Reinstall elements. Position the cover so that the rubber dust ejector is pointing downward and secure with retaining clips.

3.Slide the seat all the way back, then lift the seat to access the caps on the LH and RH hydro drives.

4.Clean the area around hydraulic reservoir cap and remove cap.

5.Wipe the dipstick clean and

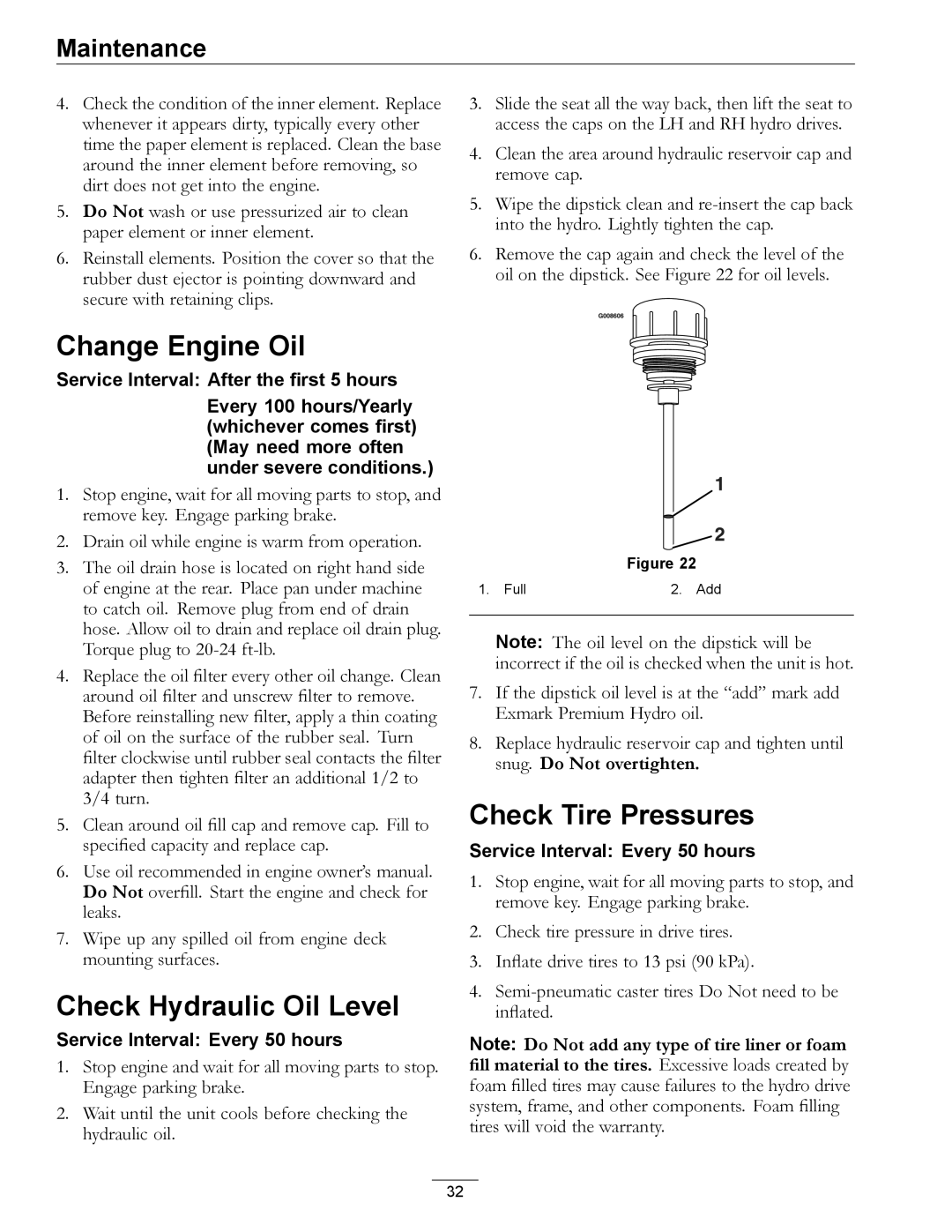

6.Remove the cap again and check the level of the oil on the dipstick. See Figure 22 for oil levels.

Change Engine Oil

Service Interval: After the first 5 hours

Every 100 hours/Yearly (whichever comes first) (May need more often under severe conditions.)

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Drain oil while engine is warm from operation.

3.The oil drain hose is located on right hand side of engine at the rear. Place pan under machine to catch oil. Remove plug from end of drain hose. Allow oil to drain and replace oil drain plug. Torque plug to

4.Replace the oil filter every other oil change. Clean around oil filter and unscrew filter to remove. Before reinstalling new filter, apply a thin coating of oil on the surface of the rubber seal. Turn filter clockwise until rubber seal contacts the filter adapter then tighten filter an additional 1/2 to 3/4 turn.

5.Clean around oil fill cap and remove cap. Fill to specified capacity and replace cap.

6.Use oil recommended in engine owner’s manual. Do Not overfill. Start the engine and check for leaks.

7.Wipe up any spilled oil from engine deck mounting surfaces.

Check Hydraulic Oil Level

Service Interval: Every 50 hours

1.Stop engine and wait for all moving parts to stop. Engage parking brake.

2.Wait until the unit cools before checking the hydraulic oil.

Figure 22

1. Full | 2. Add |

Note: The oil level on the dipstick will be incorrect if the oil is checked when the unit is hot.

7.If the dipstick oil level is at the “add” mark add Exmark Premium Hydro oil.

8.Replace hydraulic reservoir cap and tighten until snug. Do Not overtighten.

Check Tire Pressures

Service Interval: Every 50 hours

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Check tire pressure in drive tires.

3.Inflate drive tires to 13 psi (90 kPa).

4.

Note: Do Not add any type of tire liner or foam fill material to the tires. Excessive loads created by foam filled tires may cause failures to the hydro drive system, frame, and other components. Foam filling tires will void the warranty.

32