Maintenance

7.Raise the front of the machine and slide the deck left or right to remove.

8.Lower the front of the machine.

Pump Drive Belt Tension

Deck Belt Tension

Adjusting the Parking Brake

Service Interval: After the first 100 hours Every 500 hours thereafter

Check to make sure brake is adjusted properly. This procedure must be followed after the first 100 hours or when a brake component has been removed or replaced.

1.Drive the machine onto a level surface.

2.Disengage the blade control switch (PTO), move the motion control levers to the neutral locked position and set the parking brake.

3.Stop the engine, wait for all moving parts to stop, and remove the key.

4.Raise the back of the machine up and support the machine with jack stands.

![]() CAUTION

CAUTION

Raising the mower deck for service or maintenance relying solely on mechanical or hydraulic jacks could be dangerous. The mechanical or hydraulic jacks may not be enough support or may malfunction allowing the unit to fall, which could cause injury.

Do Not rely solely on mechanical or hydraulic jacks for support. Use adequate jack stands or equivalent support.

5.Remove the rear tires from the machine.

6.Remove any debris from the brake area.

7.Rotate the drive wheel release handle to the “released” position. Refer to the Drive Wheel Release Valves section in Operation.

8.Disengage the park brake.

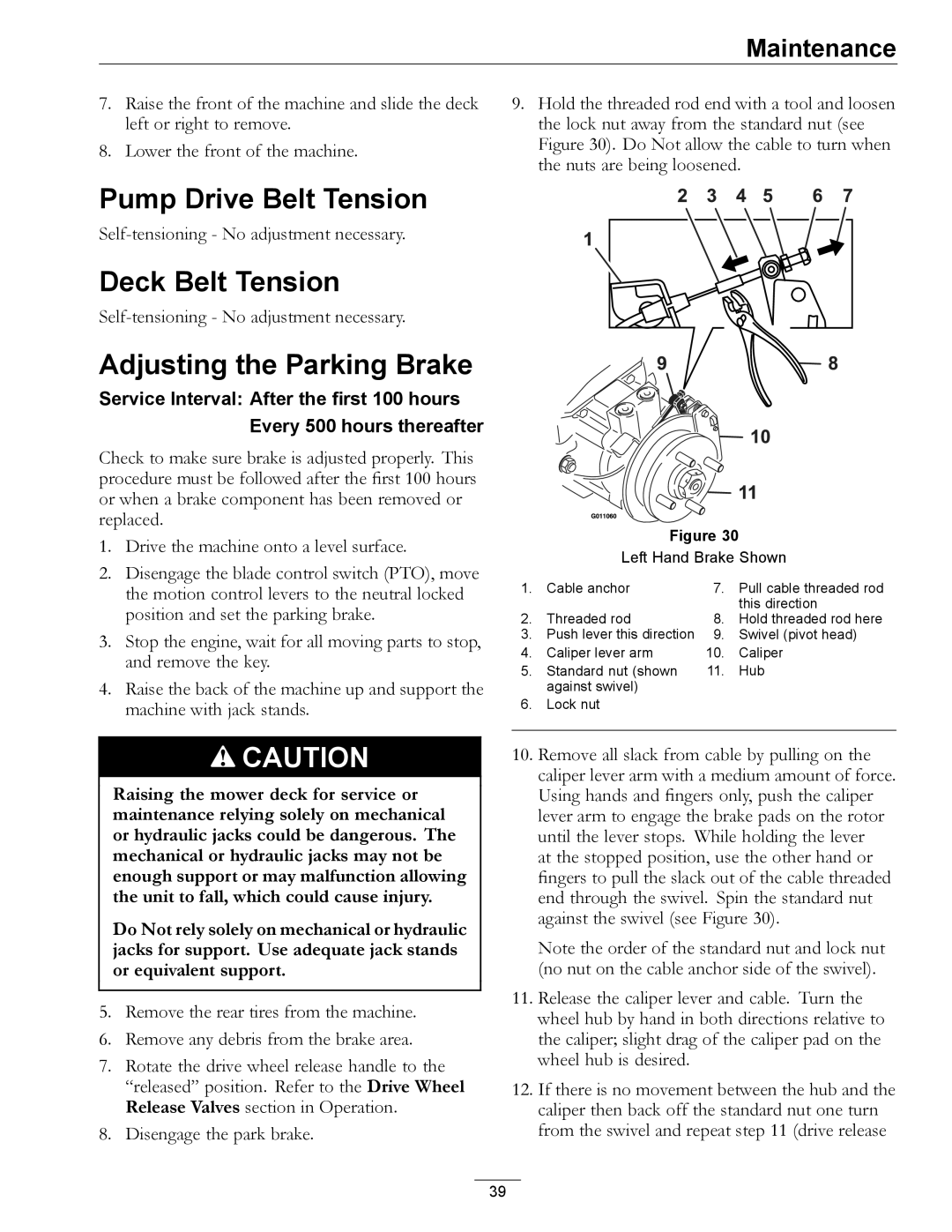

9.Hold the threaded rod end with a tool and loosen the lock nut away from the standard nut (see Figure 30). Do Not allow the cable to turn when the nuts are being loosened.

Figure 30

Left Hand Brake Shown

1. | Cable anchor | 7. | Pull cable threaded rod |

|

|

| this direction |

2. | Threaded rod | 8. | Hold threaded rod here |

3. | Push lever this direction | 9. | Swivel (pivot head) |

4. | Caliper lever arm | 10. | Caliper |

5. | Standard nut (shown | 11. | Hub |

| against swivel) |

|

|

6. | Lock nut |

|

|

10.Remove all slack from cable by pulling on the caliper lever arm with a medium amount of force. Using hands and fingers only, push the caliper lever arm to engage the brake pads on the rotor until the lever stops. While holding the lever

at the stopped position, use the other hand or fingers to pull the slack out of the cable threaded end through the swivel. Spin the standard nut against the swivel (see Figure 30).

Note the order of the standard nut and lock nut (no nut on the cable anchor side of the swivel).

11.Release the caliper lever and cable. Turn the wheel hub by hand in both directions relative to the caliper; slight drag of the caliper pad on the wheel hub is desired.

12.If there is no movement between the hub and the caliper then back off the standard nut one turn from the swivel and repeat step 11 (drive release

39