5.1.10Check tire pressures. Service Interval: 40 hrs.

a)Stop engine and remove spark plug wire(s). Check air pressure in tires; recommended tire pressure is: rear, 12 to 16 psi; pneumatic casters, 22 psi.

b)Inflate tires to pressures stated above. Measure circumference of each drive tire. Adjust tire pressures within the above range to try to make tire circumferences match as closely as possible.

NOTE: Front caster tires have permanent tire sealant installed.

5.1.11Inspect Belt wear. Service Interval: 40 hrs.

a)Stop engine and remove spark plug wire(s).

b)Remove deck support belt shield to check mower deck drive belt condition.

c)Look under engine deck to check the transmission drive and clutching belt condition.

d)Inspect wheel drive belt conditions

e)Check all idler arms to be sure they pivot freely. Disassemble, clean and grease pivot bushings if necessary.

5.1.12Inspect Blade Clutching Belt Tension.

Service Interval: Check every 2 hrs. for first 8 hrs. operation then check every 40 hrs. thereafter.

a)Stop engine.

b)Engage blade drive lever.

c)Look through the round hole in the left rear corner of the engine deck to inspect blade clutching belt tension. Bolt on blade engagement linkage bellcrank and indicator arm should align within 1/16” (See fig. 15). Refer to section 5.2.2 for adjustment.

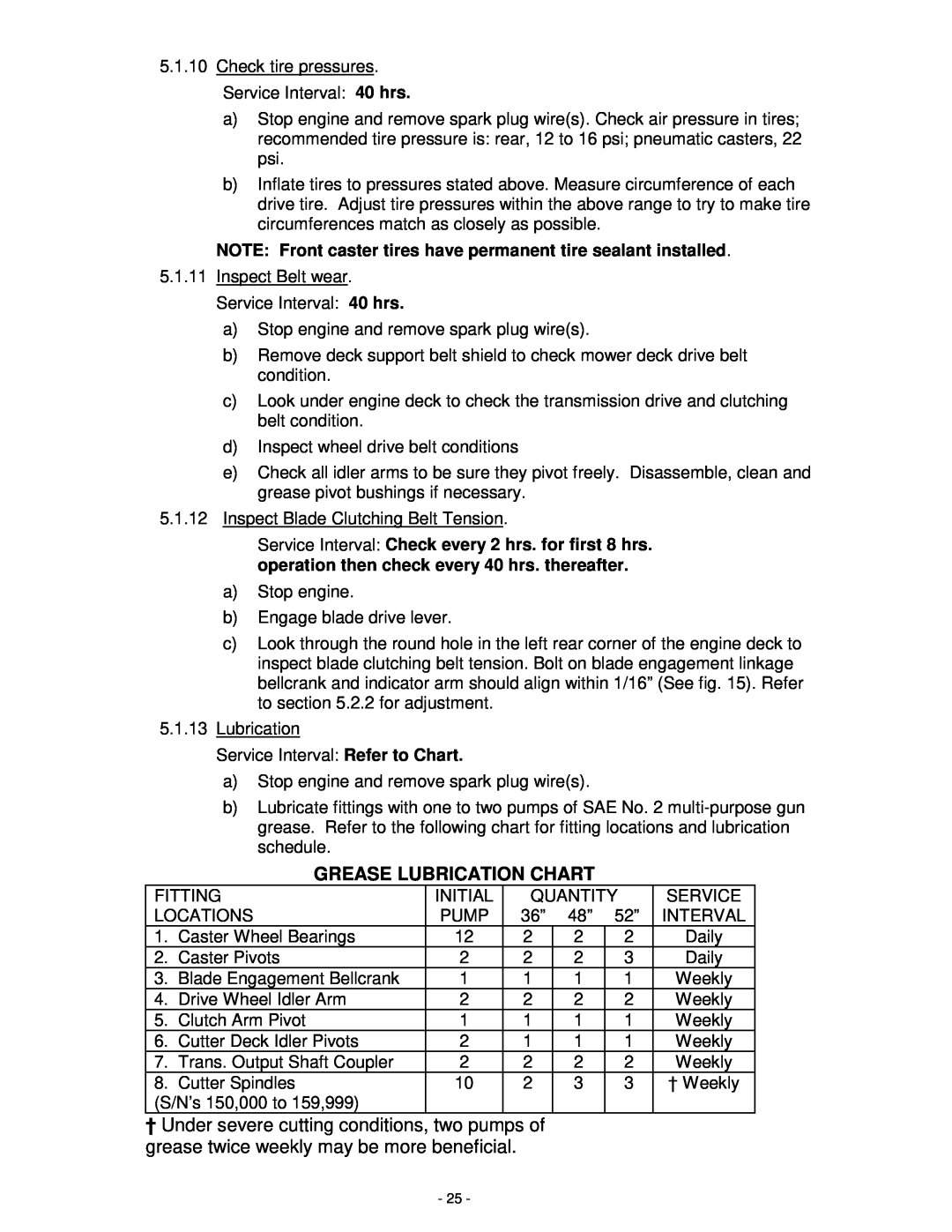

5.1.13Lubrication

Service Interval: Refer to Chart.

a)Stop engine and remove spark plug wire(s).

b)Lubricate fittings with one to two pumps of SAE No. 2

GREASE LUBRICATION CHART

FITTING | INITIAL | QUANTITY | SERVICE | |||

LOCATIONS | PUMP | 36” | 48” | 52” | INTERVAL | |

1. | Caster Wheel Bearings | 12 | 2 | 2 | 2 | Daily |

2. | Caster Pivots | 2 | 2 | 2 | 3 | Daily |

3. | Blade Engagement Bellcrank | 1 | 1 | 1 | 1 | Weekly |

4. | Drive Wheel Idler Arm | 2 | 2 | 2 | 2 | Weekly |

5. | Clutch Arm Pivot | 1 | 1 | 1 | 1 | Weekly |

6. | Cutter Deck Idler Pivots | 2 | 1 | 1 | 1 | Weekly |

7. | Trans. Output Shaft Coupler | 2 | 2 | 2 | 2 | Weekly |

8. | Cutter Spindles | 10 | 2 | 3 | 3 | † Weekly |

(S/N’s 150,000 to 159,999) |

|

|

|

|

| |

†Under severe cutting conditions, two pumps of grease twice weekly may be more beneficial.

- 25 -