Contents

TABLE OF CONTENTS

Installation, Operation and Maintenance

1.5 Through 5 Ton Split System Air Conditioner

INTRODUCTION

NOTES TO INSTALLER

What You Need To Know About Safety Instructions

CODES

DANGER

INSTALLATION Condensing Unit Location

Electrical Connections

Clearances

Opening the Service Valve Step Valve

Electrical Connections cont

SERVICE VALVE CONNECTIONS

Opening the Service Valve Straight Valve

LIQUID LINE SIZES

Precautions

CONNECT REFRIGERANT PIPING

SUCTION LINE SIZES

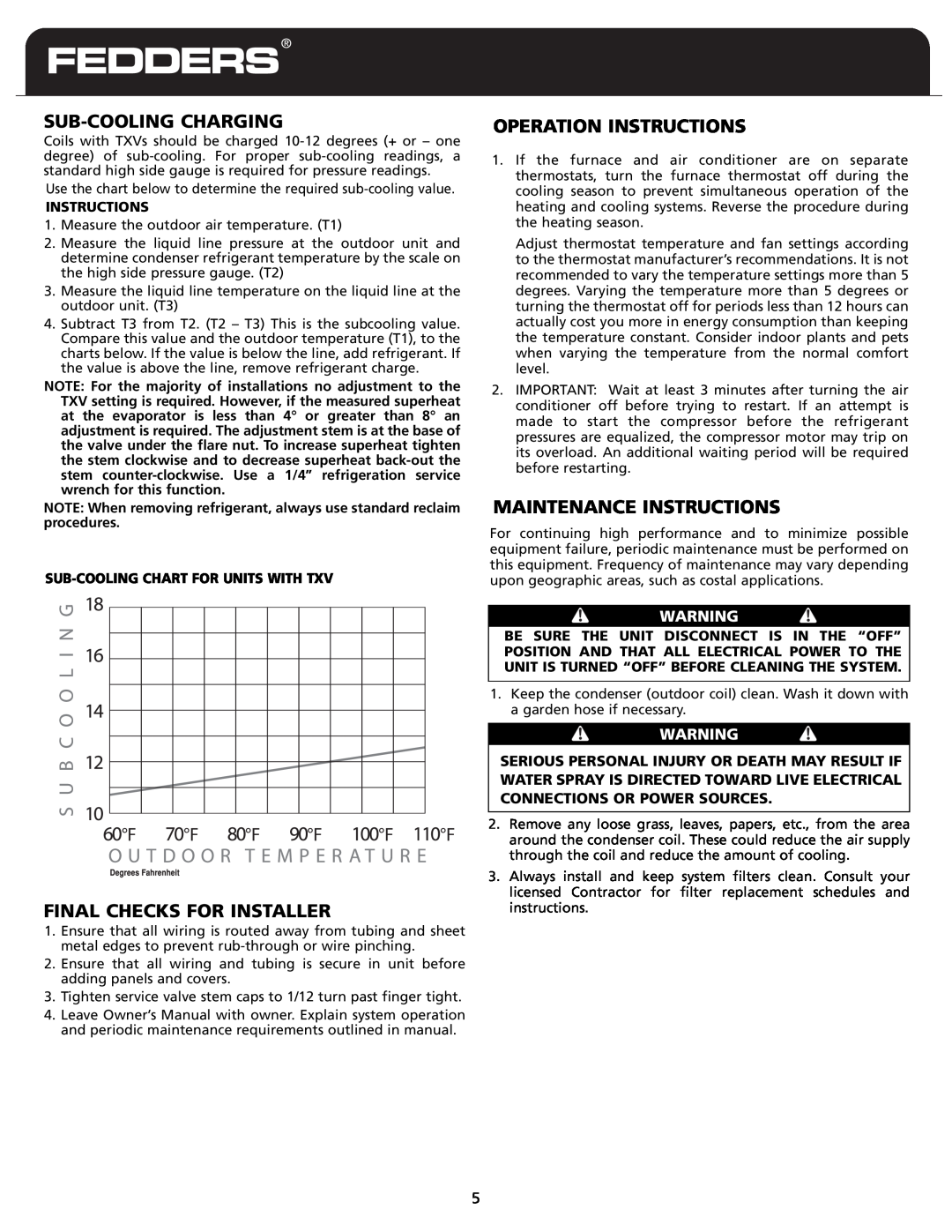

SUB-COOLINGCHARGING

MAINTENANCE INSTRUCTIONS

FINAL CHECKS FOR INSTALLER

OPERATION INSTRUCTIONS

Poduct Type

CONDENSING UNIT NOMENCLATURE

C24 A B D 1 V F

Nominal Capacity

REV. 8/06

LIMITED WARRANTY

Model C10

23-23-0418N-013