Making Butt Box Joints

Butt box joints are typically used in general box construction or for drawer construction. The Domino tenons strengthen the joint without the need for additional fasteners. The example below highlights drawer construction, but the same techniques are used on other types of box construction.

Construction Tips

►► For drawer construction with a separate drawer front, the front and rear of the box should be Captive, as shown below.

►► The drawer front is installed onto the drawer box after the box has been assembled.

►► This increases the strength of the drawer because the tenons are in shear (perpendicular) to the operation of opening and closing the drawer.

►► The ends of the side boards are concealed by the sepa- rate drawer front.

►► For drawer construction without a separate drawer front, the Sides should be Captive and the Front/Rear should be the Caps (the reverse of the image below).

►► For cabinet carcase construction, the Top/Bottom of the carcase should be Captive (also see “Making Carcase Butt Joints” on page 17).

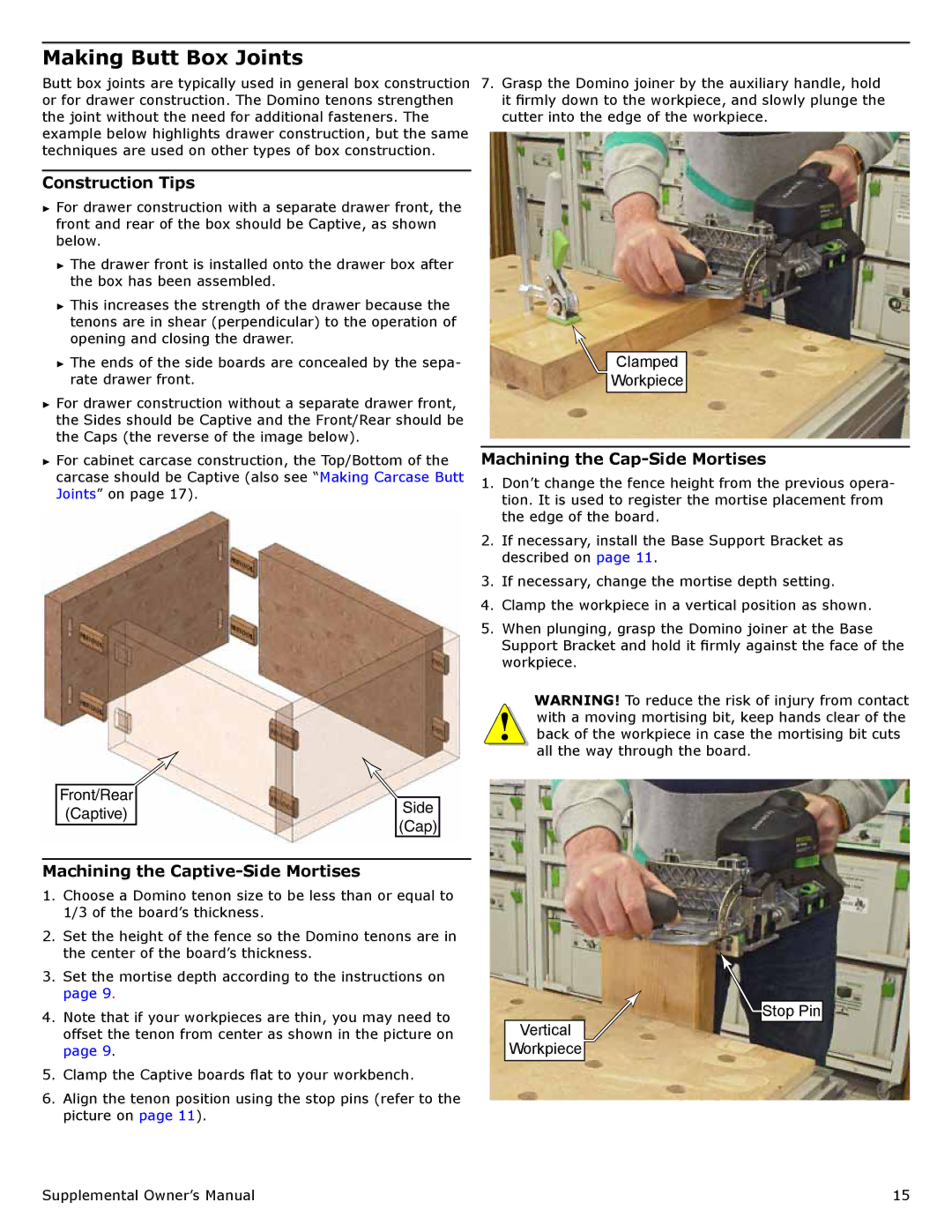

Front/Rear

(Captive)Side

(Cap)

Machining the Captive-Side Mortises

1.Choose a Domino tenon size to be less than or equal to 1/3 of the board’s thickness.

2.Set the height of the fence so the Domino tenons are in the center of the board’s thickness.

3.Set the mortise depth according to the instructions on page 9.

4.Note that if your workpieces are thin, you may need to offset the tenon from center as shown in the picture on page 9.

5.Clamp the Captive boards flat to your workbench.

6.Align the tenon position using the stop pins (refer to the picture on page 11).

7.Grasp the Domino joiner by the auxiliary handle, hold it firmly down to the workpiece, and slowly plunge the cutter into the edge of the workpiece.

Clamped

Workpiece

Machining the Cap-Side Mortises

1.Don’t change the fence height from the previous opera- tion. It is used to register the mortise placement from the edge of the board.

2.If necessary, install the Base Support Bracket as described on page 11.

3.If necessary, change the mortise depth setting.

4.Clamp the workpiece in a vertical position as shown.

5.When plunging, grasp the Domino joiner at the Base Support Bracket and hold it firmly against the face of the workpiece.

WARNING! To reduce the risk of injury from contact with a moving mortising bit, keep hands clear of the back of the workpiece in case the mortising bit cuts all the way through the board.

Stop Pin

Vertical

Workpiece

Supplemental Owner’s Manual | 15 |