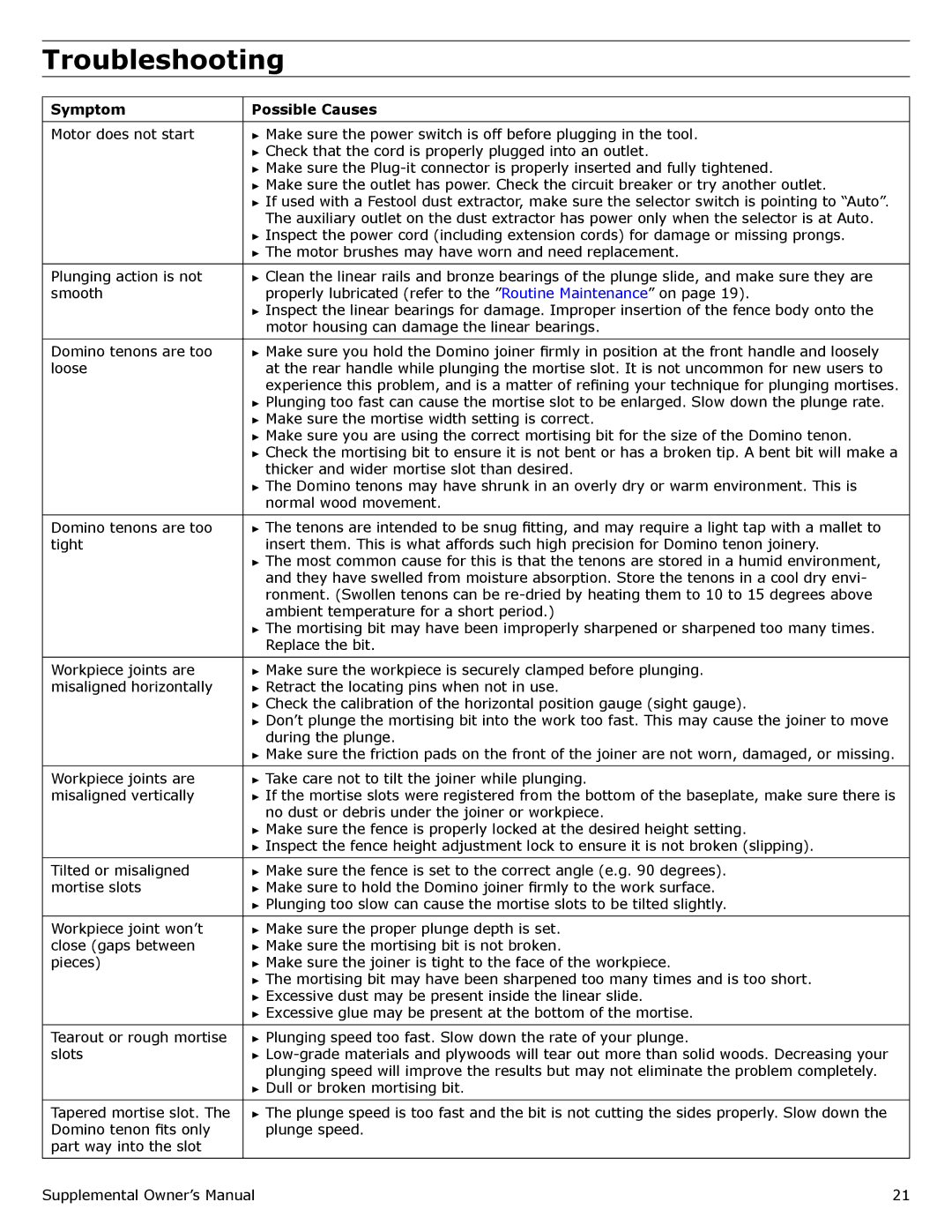

Troubleshooting

Symptom | Possible Causes |

|

|

Motor does not start | ►► Make sure the power switch is off before plugging in the tool. |

| ►► Check that the cord is properly plugged into an outlet. |

| ►► Make sure the |

| ►► Make sure the outlet has power. Check the circuit breaker or try another outlet. |

| ►► If used with a Festool dust extractor, make sure the selector switch is pointing to “Auto”. |

| The auxiliary outlet on the dust extractor has power only when the selector is at Auto. |

| ►► Inspect the power cord (including extension cords) for damage or missing prongs. |

| ►► The motor brushes may have worn and need replacement. |

Plunging action is not | ►► Clean the linear rails and bronze bearings of the plunge slide, and make sure they are |

smooth | properly lubricated (refer to the ”Routine Maintenance” on page 19). |

| ►► Inspect the linear bearings for damage. Improper insertion of the fence body onto the |

| motor housing can damage the linear bearings. |

Domino tenons are too | ►► Make sure you hold the Domino joiner firmly in position at the front handle and loosely |

loose | at the rear handle while plunging the mortise slot. It is not uncommon for new users to |

| experience this problem, and is a matter of refining your technique for plunging mortises. |

| ►► Plunging too fast can cause the mortise slot to be enlarged. Slow down the plunge rate. |

| ►► Make sure the mortise width setting is correct. |

| ►► Make sure you are using the correct mortising bit for the size of the Domino tenon. |

| ►► Check the mortising bit to ensure it is not bent or has a broken tip. A bent bit will make a |

| thicker and wider mortise slot than desired. |

| ►► The Domino tenons may have shrunk in an overly dry or warm environment. This is |

| normal wood movement. |

Domino tenons are too | ►► The tenons are intended to be snug fitting, and may require a light tap with a mallet to |

tight | insert them. This is what affords such high precision for Domino tenon joinery. |

| ►► The most common cause for this is that the tenons are stored in a humid environment, |

| and they have swelled from moisture absorption. Store the tenons in a cool dry envi- |

| ronment. (Swollen tenons can be |

| ambient temperature for a short period.) |

| ►► The mortising bit may have been improperly sharpened or sharpened too many times. |

| Replace the bit. |

Workpiece joints are | ►► Make sure the workpiece is securely clamped before plunging. |

misaligned horizontally | ►► Retract the locating pins when not in use. |

| ►► Check the calibration of the horizontal position gauge (sight gauge). |

| ►► Don’t plunge the mortising bit into the work too fast. This may cause the joiner to move |

| during the plunge. |

| ►► Make sure the friction pads on the front of the joiner are not worn, damaged, or missing. |

Workpiece joints are | ►► Take care not to tilt the joiner while plunging. |

misaligned vertically | ►► If the mortise slots were registered from the bottom of the baseplate, make sure there is |

| no dust or debris under the joiner or workpiece. |

| ►► Make sure the fence is properly locked at the desired height setting. |

| ►► Inspect the fence height adjustment lock to ensure it is not broken (slipping). |

Tilted or misaligned | ►► Make sure the fence is set to the correct angle (e.g. 90 degrees). |

mortise slots | ►► Make sure to hold the Domino joiner firmly to the work surface. |

| ►► Plunging too slow can cause the mortise slots to be tilted slightly. |

Workpiece joint won’t | ►► Make sure the proper plunge depth is set. |

close (gaps between | ►► Make sure the mortising bit is not broken. |

pieces) | ►► Make sure the joiner is tight to the face of the workpiece. |

| ►► The mortising bit may have been sharpened too many times and is too short. |

| ►► Excessive dust may be present inside the linear slide. |

| ►► Excessive glue may be present at the bottom of the mortise. |

Tearout or rough mortise | ►► Plunging speed too fast. Slow down the rate of your plunge. |

slots | ►► |

| plunging speed will improve the results but may not eliminate the problem completely. |

| ►► Dull or broken mortising bit. |

Tapered mortise slot. The | ►► The plunge speed is too fast and the bit is not cutting the sides properly. Slow down the |

Domino tenon fits only | plunge speed. |

part way into the slot |

|

Supplemental Owner’s Manual | 21 |