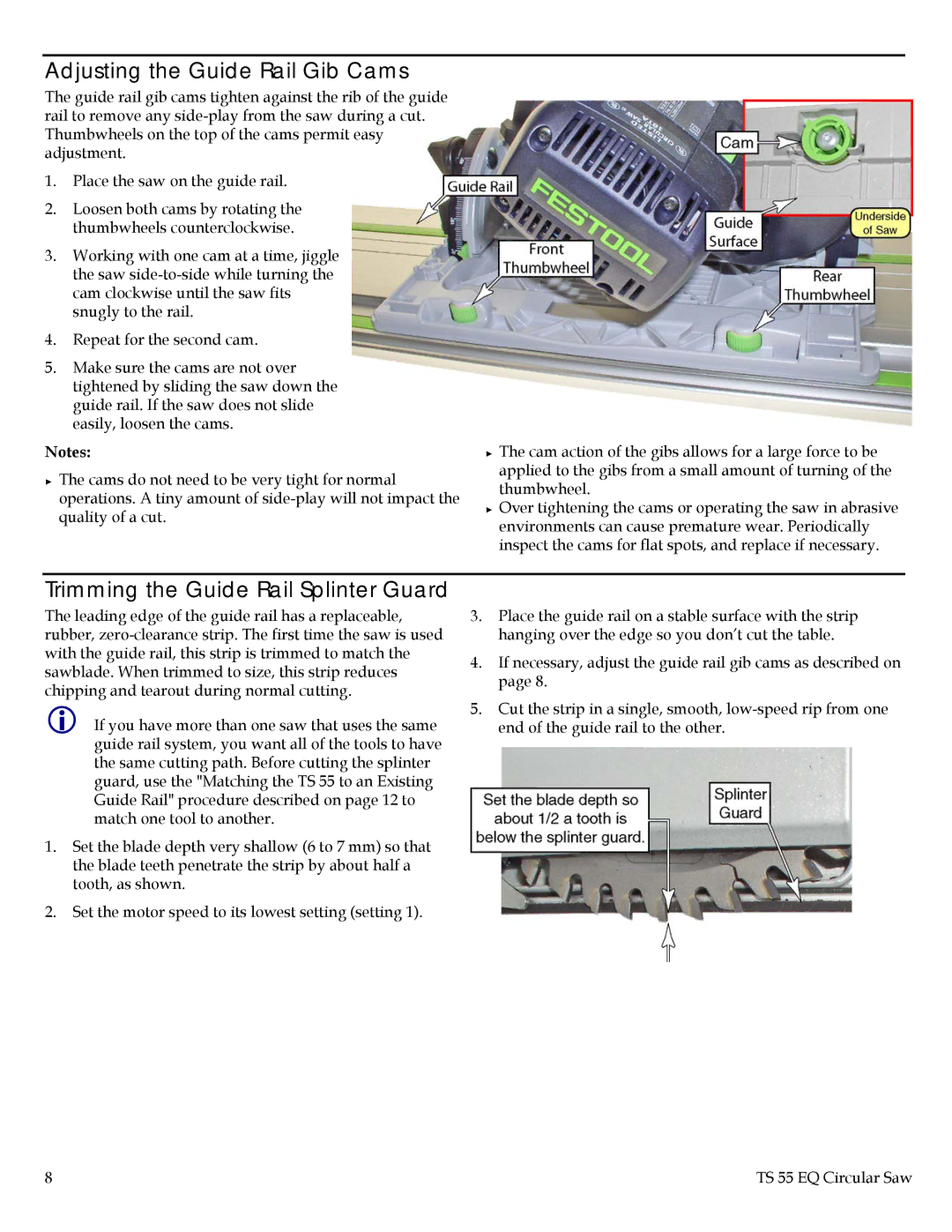

Adjusting the Guide Rail Gib Cams

The guide rail gib cams tighten against the rib of the guide rail to remove any

1.Place the saw on the guide rail.

2.Loosen both cams by rotating the thumbwheels counterclockwise.

3.Working with one cam at a time, jiggle the saw

4.Repeat for the second cam.

5.Make sure the cams are not over tightened by sliding the saw down the guide rail. If the saw does not slide easily, loosen the cams.

Notes:

►The cams do not need to be very tight for normal operations. A tiny amount of

►The cam action of the gibs allows for a large force to be applied to the gibs from a small amount of turning of the thumbwheel.

►Over tightening the cams or operating the saw in abrasive environments can cause premature wear. Periodically inspect the cams for flat spots, and replace if necessary.

Trimming the Guide Rail Splinter Guard

The leading edge of the guide rail has a replaceable, rubber,

If you have more than one saw that uses the same guide rail system, you want all of the tools to have the same cutting path. Before cutting the splinter guard, use the "Matching the TS 55 to an Existing Guide Rail" procedure described on page 12 to match one tool to another.

1.Set the blade depth very shallow (6 to 7 mm) so that the blade teeth penetrate the strip by about half a tooth, as shown.

2.Set the motor speed to its lowest setting (setting 1).

3.Place the guide rail on a stable surface with the strip hanging over the edge so you don’t cut the table.

4.If necessary, adjust the guide rail gib cams as described on page 8.

5.Cut the strip in a single, smooth,

8 | TS 55 EQ Circular Saw |