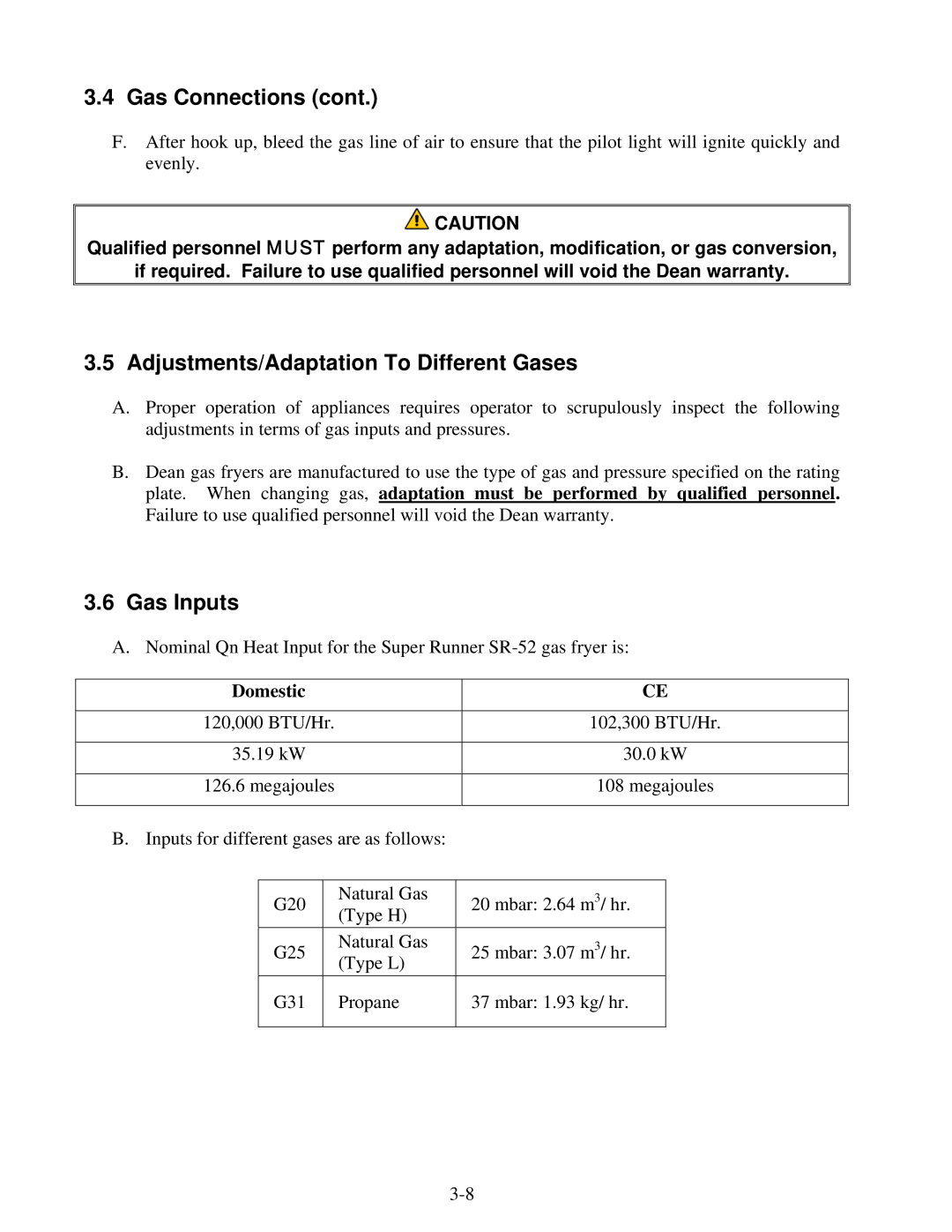

52 Series specifications

The Frymaster 52 Series stands out in the world of commercial fryers, designed specifically for establishments that prioritize efficiency, reliability, and high-quality fried products. This advanced fryer series offers a range of features that cater to the diverse needs of busy kitchens, making it an ideal choice for restaurants, catering services, and fast food outlets.One of the key highlights of the Frymaster 52 Series is its innovative fry pot design. The series utilizes a large fry pot that accommodates a significant volume of oil, allowing for larger batches of food to be cooked simultaneously. This not only enhances productivity but also ensures consistent frying results, which is crucial for any food service operation.

Another notable feature is the advanced temperature control technology. The Frymaster 52 Series incorporates a multi-stage temperature management system that ensures accurate oil temperature regulation. This feature is essential for achieving perfect frying results, as it minimizes oil degradation and helps preserve the flavor profile of the food. Furthermore, the system is equipped with an automatic recovery feature that quickly stabilizes the temperature after product loading, minimizing downtime between batches.

Energy efficiency is a significant characteristic of the Frymaster 52 Series. With its efficient heating elements, the fryer can heat oil quickly while consuming less energy compared to traditional models. This characteristic not only reduces operational costs but also contributes to a more environmentally friendly kitchen.

Safety is paramount in any commercial kitchen, and the Frymaster 52 Series is designed with this in mind. It features built-in safety mechanisms, such as high-limit thermostats, to prevent overheating and potential hazards. Additionally, the fryer is constructed with durable materials that withstand the rigors of a busy restaurant environment, ensuring longevity and reliable performance.

Another aspect that makes the Frymaster 52 Series appealing is its user-friendly interface. The fryer is equipped with intuitive controls that simplify operation, making it easy for staff to adjust settings and monitor cooking processes. This ease of use reduces training time and enhances overall kitchen efficiency.

In conclusion, the Frymaster 52 Series is an exceptional choice for any commercial kitchen seeking a reliable, efficient, and high-performing fryer. With its innovative design, advanced technologies, and safety features, the 52 Series delivers exceptional results while meeting the demands of high-volume frying.