1.8.4 Filtration Problems

The majority of filtration problems arise from operator error. One of the most common errors is placing the filter paper on the bottom of the filter pan rather than over the filter screen.

Whenever the complaint is "the pump is running, but no oil is being filtered", check the installation and size of the filter paper. Verify that the

If the pump motor overheats, its thermal overload will trip and the motor will not start until it is reset. If the pump motor does not start, press the red reset switch located on the rear of the motor. Also, reset the filter circuit breaker located under the fryer control panel. If the pump then starts, something caused the motor to overheat. Maybe several frypots were filtered one after the other and the pump got hot. Letting the motor cool down for at least a

•If solid shortening is used: Shortening solidified in the pan or filter lines.

•The operator attempted to filter unheated oil. Cold oil is thicker and causes the pump motor to work harder and overheat.

If the motor runs but the pump does not, there is a blockage in the pump. Incorrectly sized or installed paper allows food particles and sediment to pass through the filter pan and into the pump. When sediment enters the pump, the gears bind up causing the motor to overheat, tripping the thermal overload. Solidified shortening in the pump will produce the same result.

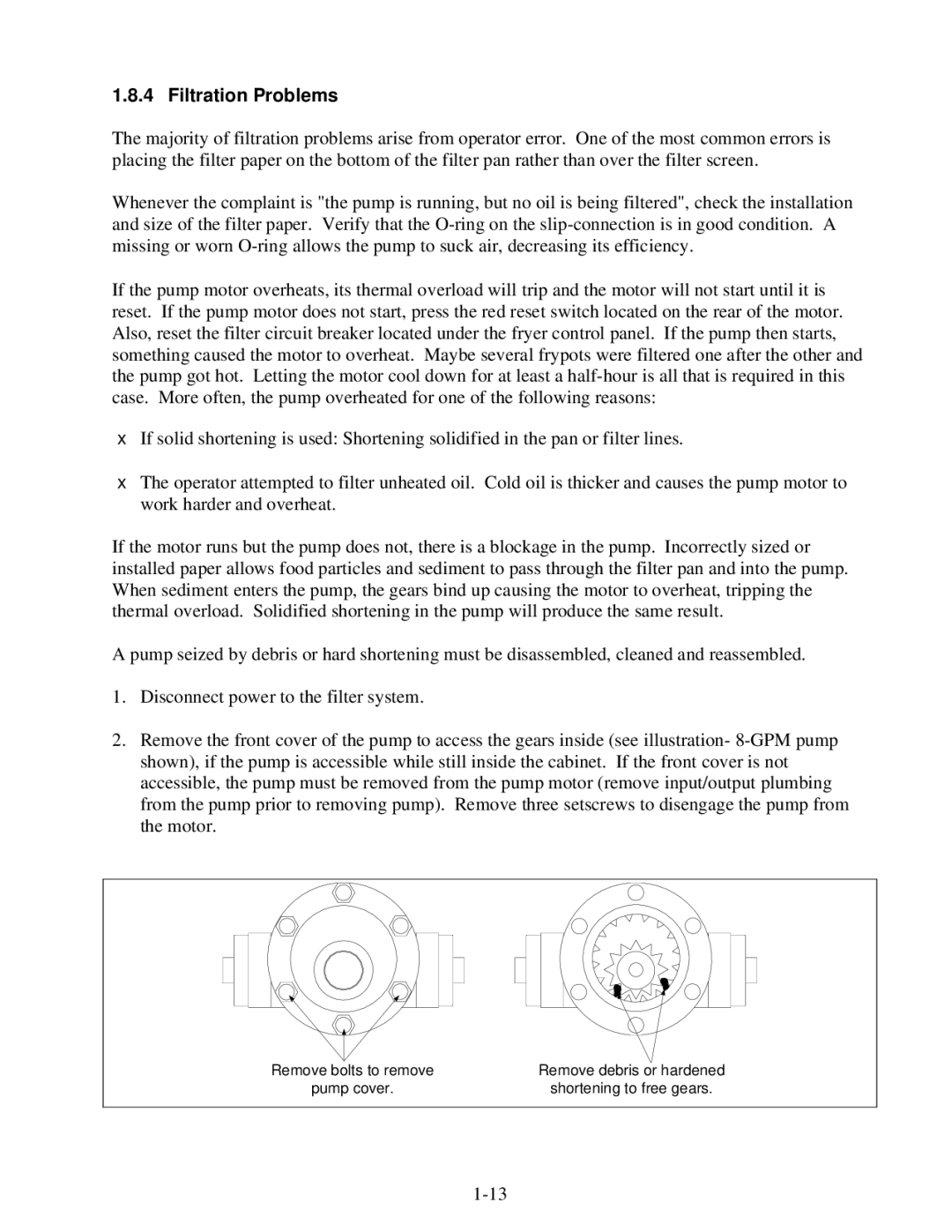

A pump seized by debris or hard shortening must be disassembled, cleaned and reassembled.

1.Disconnect power to the filter system.

2.Remove the front cover of the pump to access the gears inside (see illustration-

|

|

|

|

|

|

Remove bolts to remove | Remove debris or hardened | |

pump cover. | shortening to free gears. | |

|

|

|