YPF95 specifications

The Frymaster YPF95 is a high-performance deep fryer designed specifically for commercial kitchens that require exceptional frying capabilities while ensuring safety, efficiency, and ease of use. This unit is equipped with advanced technology and features that make it a favorite among chefs and restaurant operators.One of the standout characteristics of the Frymaster YPF95 is its high-efficiency heating system. The fryer operates with an incredible thermal efficiency, reducing energy consumption while providing consistent frying temperatures. This not only enhances the quality of fried food but can also lead to significant savings on energy bills, an essential factor for any busy kitchen.

The YPF95 comes with a large 50-pound oil capacity, making it ideal for high-volume frying operations. Its spacious frying vat allows for the frying of large batches of food, which can significantly streamline kitchen workflow during peak hours. Additionally, the fryer is designed with versatility in mind, suitable for frying a wide range of food items from french fries to chicken wings, ensuring that any restaurant’s menu can be reliably serviced.

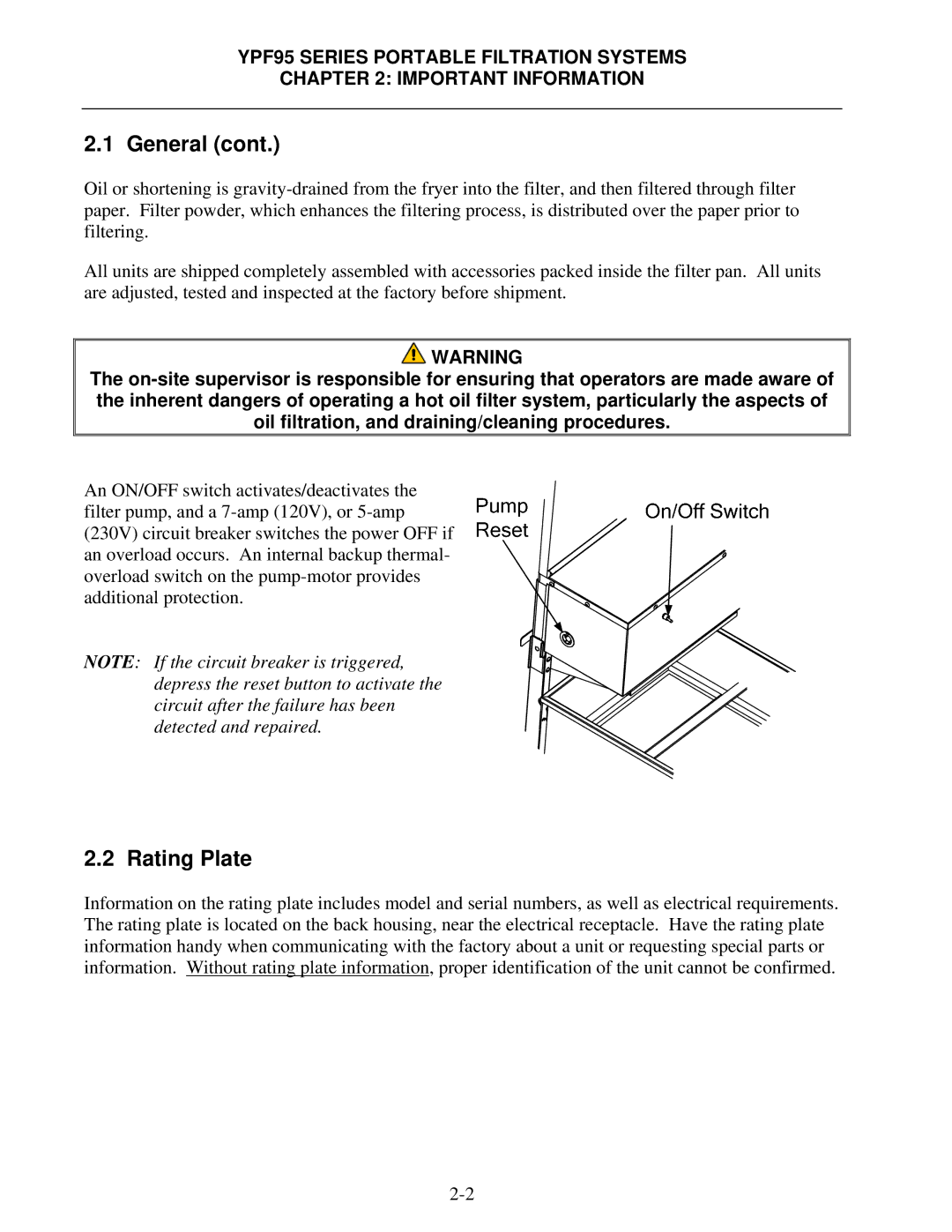

Safety features are paramount in the design of the Frymaster YPF95. It incorporates a built-in filtration system that removes impurities from the oil, prolonging its life and ensuring that meals are cooked in clean, fresh oil. This system not only maintains food quality but also reduces the risk of oil-related accidents, promoting a safer kitchen environment.

Another key technology integrated into the YPF95 is its programmable controls. The fryer is equipped with a digital control system that allows users to set precise cooking times and temperatures. This feature ensures consistency in cooking and can be a valuable addition for establishments that are training new staff, as it simplifies the frying process.

Moreover, the Frymaster YPF95 is designed with ease of maintenance in mind. The removable oil drain valve and easy-access filtration system facilitate efficient cleaning and oil replacement procedures. This user-friendly design minimizes downtime and helps maintain optimal cooking conditions.

In summary, the Frymaster YPF95 is a robust and efficient fryer capable of meeting the rigorous demands of the foodservice industry. Its combination of high-capacity volume, safety features, and advanced technology makes it a wise investment for any commercial kitchen looking to enhance productivity while delivering top-quality fried foods.