GBC 3064WF

Start Laminating

1.At this point you should have your laminator Webbed with the appropriate material for your application.

2.The feed table should be in the normal operating position.

3.Close the main and Pull roll nips. Rollers should be closed.

4.Speed is set to 3 or less and “FRONT” ( ![]() ) motor direction is selected.

) motor direction is selected.

5.Press the “START” (![]() ) button.

) button.

6.Set main roller pressure between 40% – 60% for laminating by turning the main roll lift handle.

CAUTION: If using PSA film, an air pocket may result between the main rollers and pull rollers. Raise the pull rollers to allow the air Pocket to pass.

7.Make any necessary film brake tension adjustments, pull/main roller pressure, and clutch and/ or rewind brake tension adjustments.

8.Position the item to be laminated on the feed table.

9.Align the leading edge of the item parallel to the heat roller nip (Fig. 25).

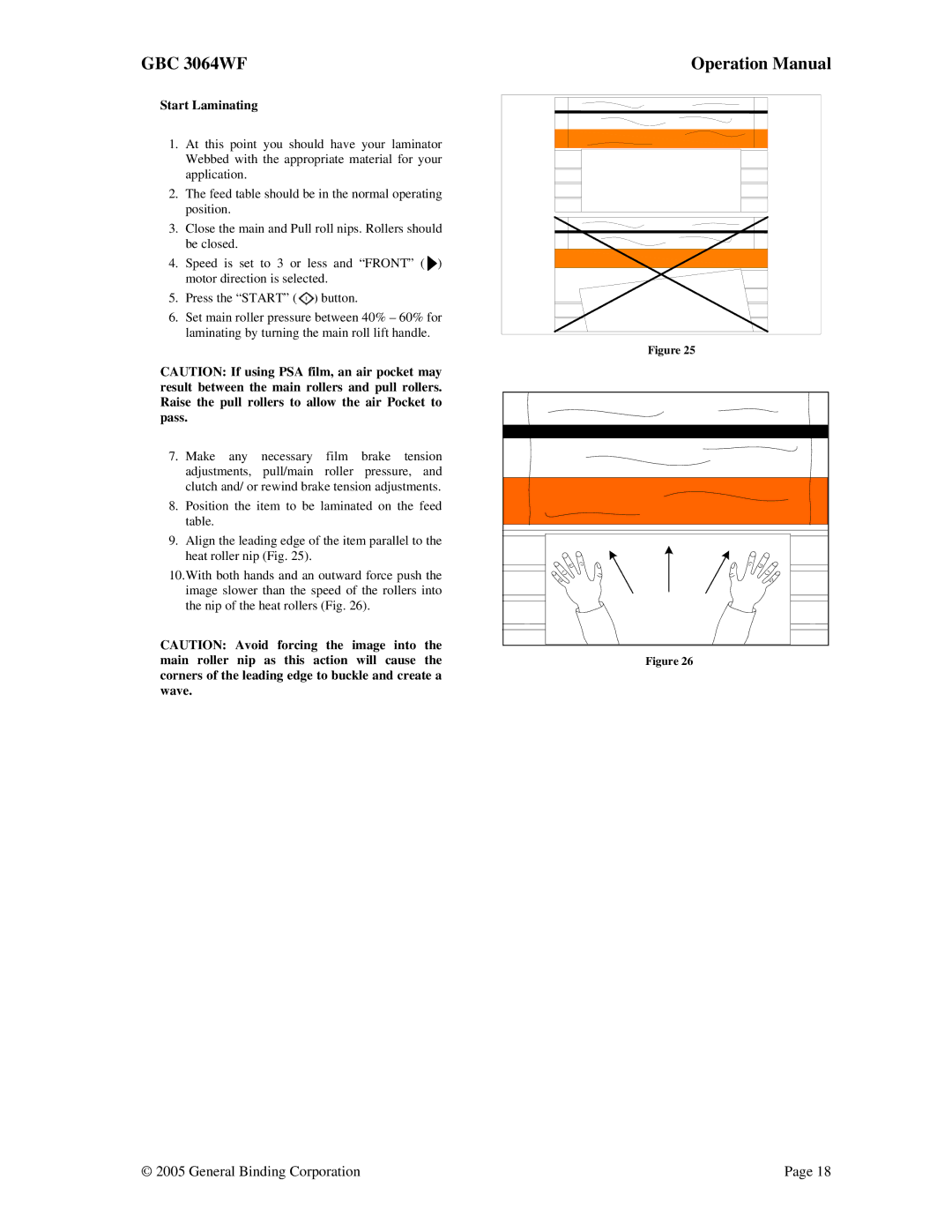

10.With both hands and an outward force push the image slower than the speed of the rollers into the nip of the heat rollers (Fig. 26).

CAUTION: Avoid forcing the image into the main roller nip as this action will cause the corners of the leading edge to buckle and create a wave.

Operation Manual

Figure 25

Figure 26

© 2005 General Binding Corporation | Page 18 |