GBC 3064WF | Operation Manual |

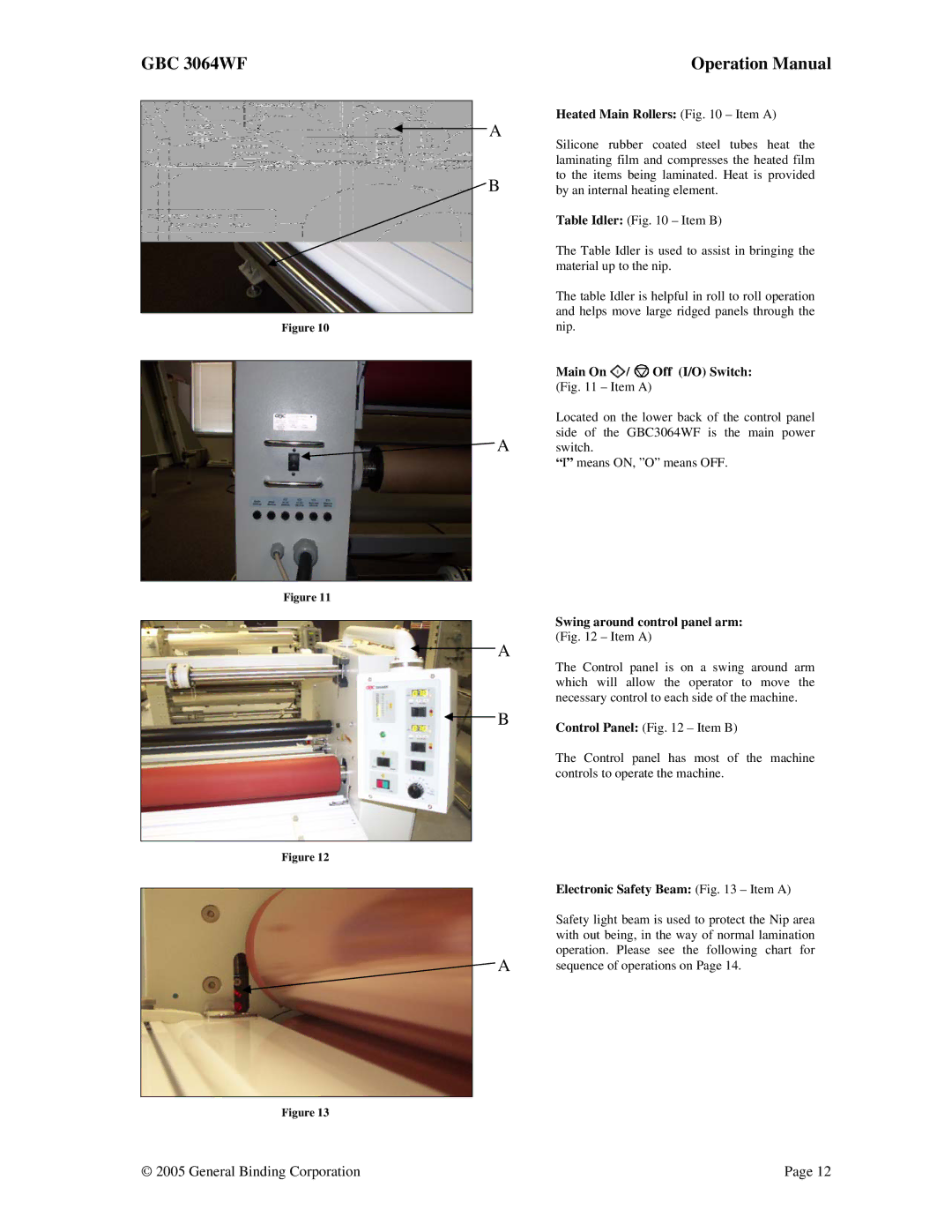

Figure 10

A | Heated Main Rollers: (Fig. 10 – Item A) | |||

Silicone rubber coated steel tubes heat the | ||||

| ||||

| laminating film and compresses the heated film | |||

B | to the items being laminated. Heat is provided | |||

by an internal heating element. | ||||

| Table Idler: (Fig. 10 – Item B) | |||

| The Table Idler is used to assist in bringing the | |||

| material up to the nip. | |||

| The table Idler is helpful in roll to roll operation | |||

| and helps move large ridged panels through the | |||

| nip. |

|

| |

| Main On | / | Off (I/O) Switch: | |

| (Fig. 11 – Item A) |

| ||

| Located on the lower back of the control panel | |||

A | side of the GBC3064WF is the main power | |||

switch. |

|

| ||

“I” means ON, ”O” means OFF.

Figure 11

A

Swing around control panel arm: (Fig. 12 – Item A)

The Control panel is on a swing around arm which will allow the operator to move the necessary control to each side of the machine.

BControl Panel: (Fig. 12 – Item B)

The Control panel has most of the machine controls to operate the machine.

Figure 12

| Electronic Safety Beam: (Fig. 13 – Item A) |

| Safety light beam is used to protect the Nip area |

| with out being, in the way of normal lamination |

A | operation. Please see the following chart for |

sequence of operations on Page 14. |

Figure 13

© 2005 General Binding Corporation | Page 12 |