Section 1 — General Information

Centurion

1.10 SPECIFICATIONS

1.10.1 GENERATOR

|

|

| ||||

| Model | 004913 |

|

| 004912 |

|

| Rated Max. Cont. | 25 |

|

| 15 |

|

| AC Power Output (kW) |

|

|

|

|

|

| Rated voltage (volts) |

|

| 120/240 |

|

|

| No. of Rotor Poles | 2 |

|

| 4 |

|

| Driven Speed of Rotor | 3600 |

|

| 1800 |

|

| Rotor Excitation System | Direct excited brush type |

| |||

| Type of Stator |

|

| 4 Wire |

| |

| Rotor/Stator Insulation |

| Class F/H |

| ||

|

|

|

|

|

|

|

1.10.2 ENGINE

Make | Mitsubishi |

Displacement | 92 inches3 (1.5 liters) |

Cylinder Arrangement | 4, |

Valve Arrangement | Overhead Cam |

Firing Order | |

Number of Main Bearings | 5 |

Compression Ratio | 9 to 1 |

No. of Teeth on Flywheel | 104 |

Ignition Timing |

|

at 1800 rpm | 35 degrees BTDC |

at 3600 rpm | 43 degrees BTDC |

Spark Plug Gap | |

Recommended Spark Plugs |

|

Champion | RN11YC4 |

Oil Pressure | |

Crankcase Oil Capacity | 4.0 U.S. quarts (3.8 liters) |

Recommended Engine Oil | SAE |

Type of Cooling System | Pressurized, closed recovery |

Cooling Fan | Pusher Type |

Cooling System Capacity | 2 U.S. gallons (7.6 liters) |

Recommended Coolant | Use a |

| ethylene glycol base and |

| deionized water. |

1.11 FUEL CONSUMPTION

25 kW Models

Using Natural Gas | ..............................441 cu. ft. per hour |

Using LP Gas | 175 cubic ft.(4.8 gal.) per hour |

15 kW Models |

|

Using Natural Gas | ..............................277 cu. ft. per hour |

Using LP Gas | 110 cubic ft.(3.1 gal.) per hour |

Fuel pressure for a natural gas set up should be five inches to 14 inches of water column (0.18 to 0.5 psi) at all load ranges.

Fuel pressure for an LP vapor set up should be 11 inches to 14 inches of water column (0.4 to 0.5 psi) at all load ranges.

NOTE:

A seperate gas line and regulator may be needed to assure proper gas pressure to the generator. Improper gas pressure can cause hard starting and could affect engine durability.

1.12RECONFIGURING THE FUEL SYSTEM

NOTE:

All models are configured for natural gas from the factory.

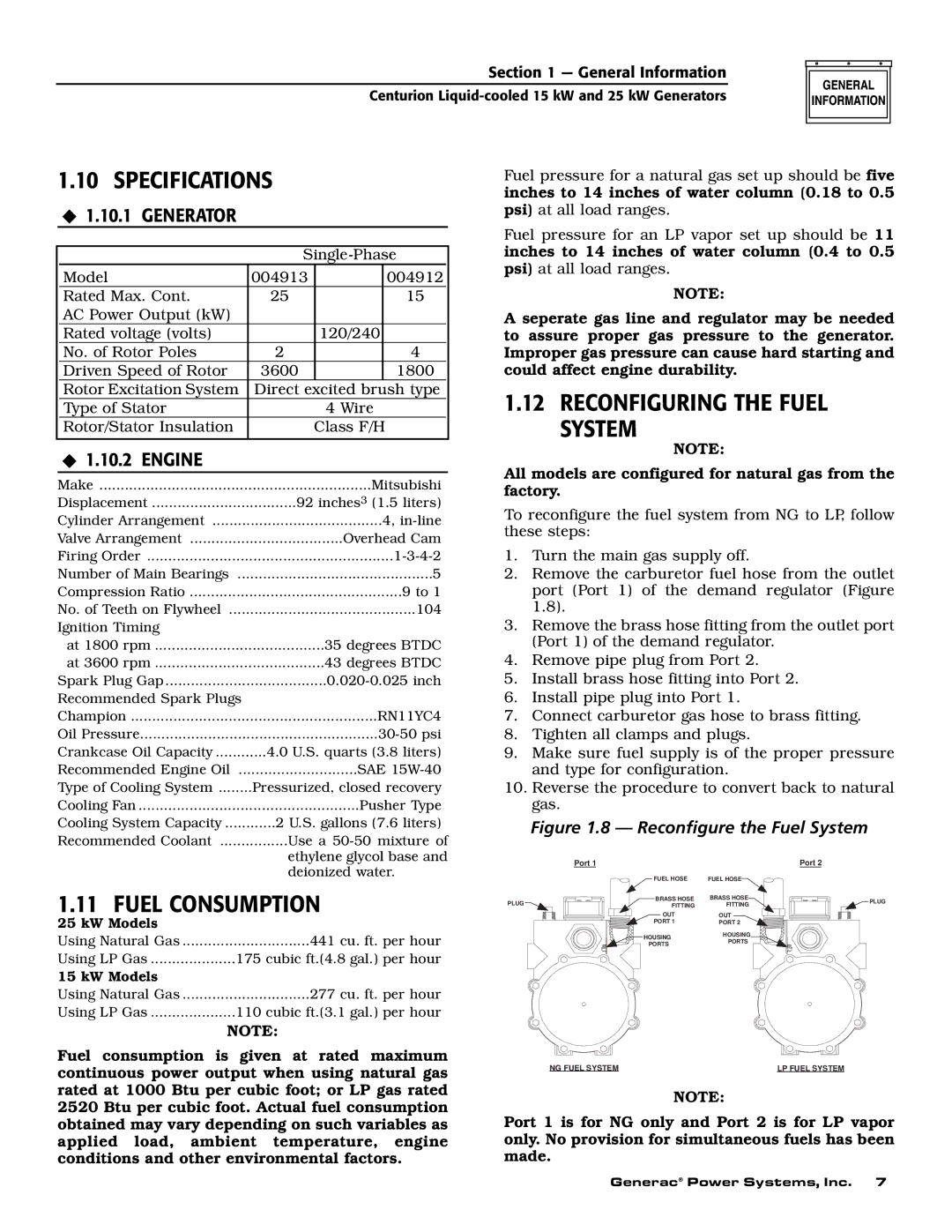

To reconfigure the fuel system from NG to LP, follow these steps:

1.Turn the main gas supply off.

2.Remove the carburetor fuel hose from the outlet port (Port 1) of the demand regulator (Figure 1.8).

3.Remove the brass hose fitting from the outlet port (Port 1) of the demand regulator.

4.Remove pipe plug from Port 2.

5.Install brass hose fitting into Port 2.

6.Install pipe plug into Port 1.

7.Connect carburetor gas hose to brass fitting.

8.Tighten all clamps and plugs.

9.Make sure fuel supply is of the proper pressure and type for configuration.

10.Reverse the procedure to convert back to natural gas.

Figure 1.8 — Reconfigure the Fuel System

| Port 1 |

| Port 2 | |

| FUEL HOSE | FUEL HOSE |

| |

PLUG | BRASS HOSE | BRASS HOSE | PLUG | |

FITTING | FITTING | |||

| ||||

| OUT | OUT |

| |

| PORT 1 | PORT 2 |

| |

| HOUSING | HOUSING |

| |

| PORTS |

| ||

| PORTS |

| ||

|

|

|

NOTE:

Fuel consumption is given at rated maximum continuous power output when using natural gas rated at 1000 Btu per cubic foot; or LP gas rated 2520 Btu per cubic foot. Actual fuel consumption obtained may vary depending on such variables as applied load, ambient temperature, engine conditions and other environmental factors.

NG FUEL SYSTEM | LP FUEL SYSTEM |

NOTE:

Port 1 is for NG only and Port 2 is for LP vapor only. No provision for simultaneous fuels has been made.

Generac® Power Systems, Inc. 7