Section 2 – Operation

PRIMEPACT 50 Recreational Vehicle Generator

When the heat riser is in the WINTER (up) position, air is drawn from the lower intake tube, which is positioned to draw the heated air near the exhaust manifold.

To prevent carburetor icing, the owner/operator should physically position the heat riser to the prop- er position dependent on the temperature.

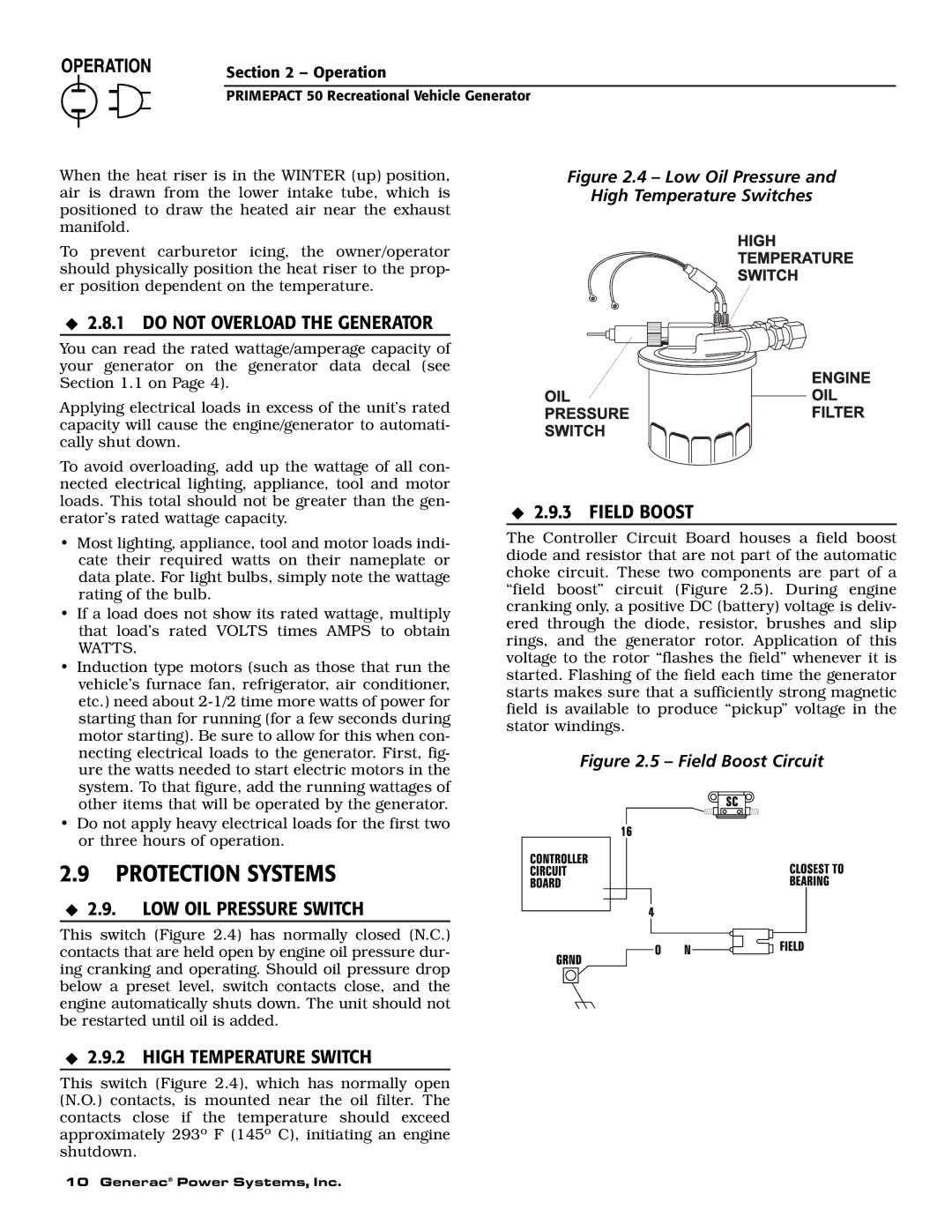

Figure 2.4 – Low Oil Pressure and

High Temperature Switches

◆2.8.1 DO NOT OVERLOAD THE GENERATOR

You can read the rated wattage/amperage capacity of your generator on the generator data decal (see Section 1.1 on Page 4).

Applying electrical loads in excess of the unit’s rated capacity will cause the engine/generator to automati- cally shut down.

To avoid overloading, add up the wattage of all con- nected electrical lighting, appliance, tool and motor loads. This total should not be greater than the gen- erator’s rated wattage capacity.

•Most lighting, appliance, tool and motor loads indi- cate their required watts on their nameplate or data plate. For light bulbs, simply note the wattage rating of the bulb.

•If a load does not show its rated wattage, multiply that load’s rated VOLTS times AMPS to obtain

WATTS.

•Induction type motors (such as those that run the vehicle’s furnace fan, refrigerator, air conditioner, etc.) need about

•Do not apply heavy electrical loads for the first two or three hours of operation.

2.9PROTECTION SYSTEMS

◆2.9. LOW OIL PRESSURE SWITCH

This switch (Figure 2.4) has normally closed (N.C.) contacts that are held open by engine oil pressure dur- ing cranking and operating. Should oil pressure drop below a preset level, switch contacts close, and the engine automatically shuts down. The unit should not be restarted until oil is added.

◆2.9.3 FIELD BOOST

The Controller Circuit Board houses a field boost diode and resistor that are not part of the automatic choke circuit. These two components are part of a “field boost” circuit (Figure 2.5). During engine cranking only, a positive DC (battery) voltage is deliv- ered through the diode, resistor, brushes and slip rings, and the generator rotor. Application of this voltage to the rotor “flashes the field” whenever it is started. Flashing of the field each time the generator starts makes sure that a sufficiently strong magnetic field is available to produce “pickup” voltage in the stator windings.

Figure 2.5 – Field Boost Circuit

◆2.9.2 HIGH TEMPERATURE SWITCH

This switch (Figure 2.4), which has normally open (N.O.) contacts, is mounted near the oil filter. The contacts close if the temperature should exceed approximately 293º F (145º C), initiating an engine shutdown.

10 Generac® Power Systems, Inc.