Section 2 – Operation

PRIMEPACT 50 Recreational Vehicle Generator

◆2.9.4 OVERVOLTAGE PROTECTION

A

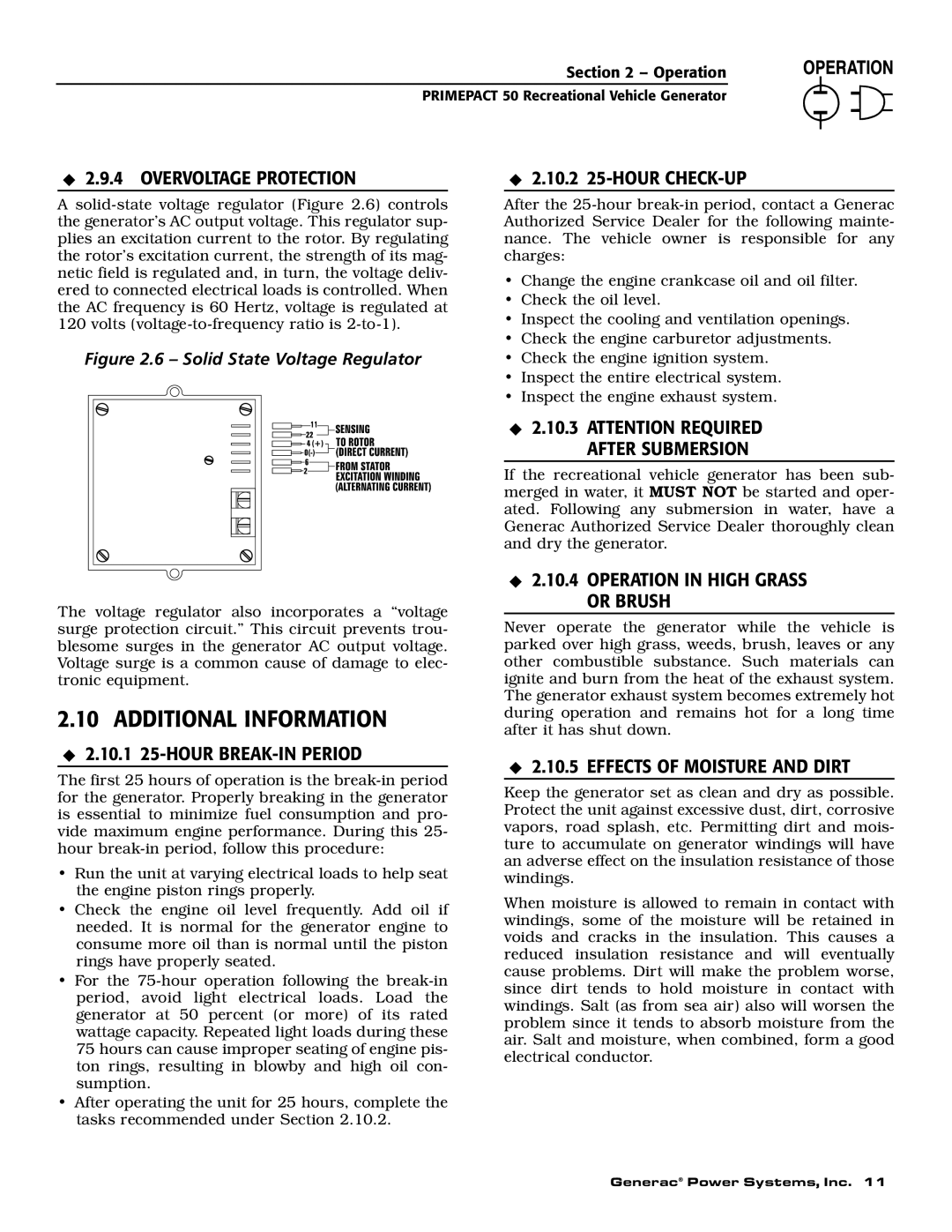

Figure 2.6 – Solid State Voltage Regulator

◆2.10.2 25-HOUR CHECK-UP

After the

•Change the engine crankcase oil and oil filter.

•Check the oil level.

•Inspect the cooling and ventilation openings.

•Check the engine carburetor adjustments.

•Check the engine ignition system.

•Inspect the entire electrical system.

•Inspect the engine exhaust system.

◆2.10.3 ATTENTION REQUIRED

AFTER SUBMERSION

If the recreational vehicle generator has been sub- merged in water, it MUST NOT be started and oper- ated. Following any submersion in water, have a Generac Authorized Service Dealer thoroughly clean and dry the generator.

The voltage regulator also incorporates a “voltage surge protection circuit.” This circuit prevents trou- blesome surges in the generator AC output voltage. Voltage surge is a common cause of damage to elec- tronic equipment.

2.10 ADDITIONAL INFORMATION

◆2.10.1 25-HOUR BREAK-IN PERIOD

The first 25 hours of operation is the

•Run the unit at varying electrical loads to help seat the engine piston rings properly.

•Check the engine oil level frequently. Add oil if needed. It is normal for the generator engine to consume more oil than is normal until the piston rings have properly seated.

•For the

•After operating the unit for 25 hours, complete the tasks recommended under Section 2.10.2.

◆2.10.4 OPERATION IN HIGH GRASS OR BRUSH

Never operate the generator while the vehicle is parked over high grass, weeds, brush, leaves or any other combustible substance. Such materials can ignite and burn from the heat of the exhaust system. The generator exhaust system becomes extremely hot during operation and remains hot for a long time after it has shut down.

◆2.10.5 EFFECTS OF MOISTURE AND DIRT

Keep the generator set as clean and dry as possible. Protect the unit against excessive dust, dirt, corrosive vapors, road splash, etc. Permitting dirt and mois- ture to accumulate on generator windings will have an adverse effect on the insulation resistance of those windings.

When moisture is allowed to remain in contact with windings, some of the moisture will be retained in voids and cracks in the insulation. This causes a reduced insulation resistance and will eventually cause problems. Dirt will make the problem worse, since dirt tends to hold moisture in contact with windings. Salt (as from sea air) also will worsen the problem since it tends to absorb moisture from the air. Salt and moisture, when combined, form a good electrical conductor.

Generac® Power Systems, Inc. 11