Liquid-cooled,Prepackaged Standby Generators

SHOULD ATTEMPT INSTALLATION

Owner’s Manual

This manual should remain with the unit

‹HOW TO OBTAIN SERVICE

AUTHORIZED SERVICE DEALER LOCATION

‹OPERATION AND MAINTENANCE

INTRODUCTION

Table of Contents

INTRODUCTION

Parts of the generator are rotating and/or hot

GENERAL HAZARDS

Despite the safe design of this generator

EXPLOSION HAZARDS

ELECTRICAL HAZARDS

FIRE HAZARDS

‹STANDARDS INDEX

1.3AUTOMATIC SYSTEM OPERATION

1.2TRANSFER SWITCH

1.1GENERATOR

1.4GENERATOR AC CONNECTION SYSTEMS

‹1.7.3 LOW COOLANT LEVEL SWITCH

‹1.7.1 LOW OIL PRESSURE SWITCH

‹1.7.2 HIGH COOLANT TEMPERATURE SWITCH

Figure 1.4 - Low Oil Pressure Switch

‹1.8.1 UNPACKING PRECAUTIONS

1.10 SPECIFICATIONS

‹1.7.6 LOW BATTERY

1.8UNPACKING

1.11 FUEL CONSUMPTION

1.12RECONFIGURING THE FUEL SYSTEM FOR LP VAPOR

Figure 1.8 — Reconfigure the Fuel System

‹ 1.10.2 GENERATOR

1.13 ENGINE OIL RECOMMENDATIONS

1.15 BEFORE INSTALLATION

2.1STANDBY GENERATOR INSTALLATION

1.14 COOLANT RECOMMENDATIONS

2.2GENERATOR LOCATION

2.3GENERATOR MOUNTING AND SUPPORT

2.4BASIC STANDBY ELECTRIC SYSTEM

‹2.1.2 OTHER PUBLISHED STANDARDS

2.6TOTAL CIRCUIT ISOLATION METHOD

2.9USING AN ENGINEERED “GTS” TRANSFER SWITCH

2.5EMERGENCY CIRCUIT ISOLATION METHOD

2.7GROUNDING THE GENERATOR

‹2.10.1 VENTED BATTERIES

2.10BATTERY INSTALLATION

Pos2 OFF — Standard Prepackaged ATS Application

Standby generators installed with automatic

2.11 PREPARATION BEFORE START-UP

3.1ENGINEERED GTS TRANSFER SWITCH

‹2.11.2 TRANSFER SWITCH

‹2.11.1 PRIOR TO INITIAL START-UP

‹3.2.5 SET EXERCISE TIME SWITCH

‹3.2.2 FAULT INDICATOR LEDS

‹3.2.1 AUTO/OFF/MANUAL SWITCH

3.2CONTROL CONSOLE COMPONENTS

‹3.2.6 SYSTEM READY LED

3.4ENGINE GOVERNOR ADJUSTMENTS

3.3MANUAL TRANSFER AND START-UP

3.6AUTOMATIC OPERATION

Figure 3.2 — Engine Governor Adjustment

Figure 3.3 - “Set Exercise Time” Switch

3.7WEEKLY EXERCISE CYCLE

B. ONCE EVERY SIX MONTHS

3.8CONTROL BOARD DIP SWITCH SETTINGS

A. EVERY THREE MONTHS

C. ONCE ANNUALLY

4.4CYLINDER HEAD PROCEDURE

4.2EXHAUST MANIFOLD PROCEDURE

4.3INTAKE MANIFOLD PROCEDURE

Figure 4.1 — Intake Manifold Installation

ENGINE DC ELECTRICAL SYSTEM

4.8MAINTENANCE OWNER/ OPERATOR CAN PERFORM

4.6OVERLOAD PROTECTION FOR

4.7CHECKING FLUID LEVELS

‹4.8.8 CHECK FAN BELT

‹4.8.11 CHANGING THE ENGINE AIR CLEANER

Figure 4.4 – Setting the Spark Plug Gap

‹4.8.9 INSPECT ENGINE GOVERNOR

‹4.9.2 BATTERY

4.9MISCELLANEOUS MAINTENANCE

‹4.9.1 CLEANING THE GENERATOR

‹4.9.3 BATTERY MAINTENANCE

4.10 SCHEDULED MAINTENANCE

Service Maintenance Interval Information

Tasks

Maintenance

Level

Maintenance

CAUSE

TROUBLESHOOTING POINTS

PROBLEM

CORRECTION

Section 6 — Notes

26 Generac Power Systems, Inc

Section 7 - Electrical Data

Generac Power Systems, Inc.

28 Generac Power Systems, Inc

Generac Power Systems, Inc

30 Generac Power Systems, Inc

Generac Power Systems, Inc.

32 Generac Power Systems, Inc

Generac Power Systems, Inc.

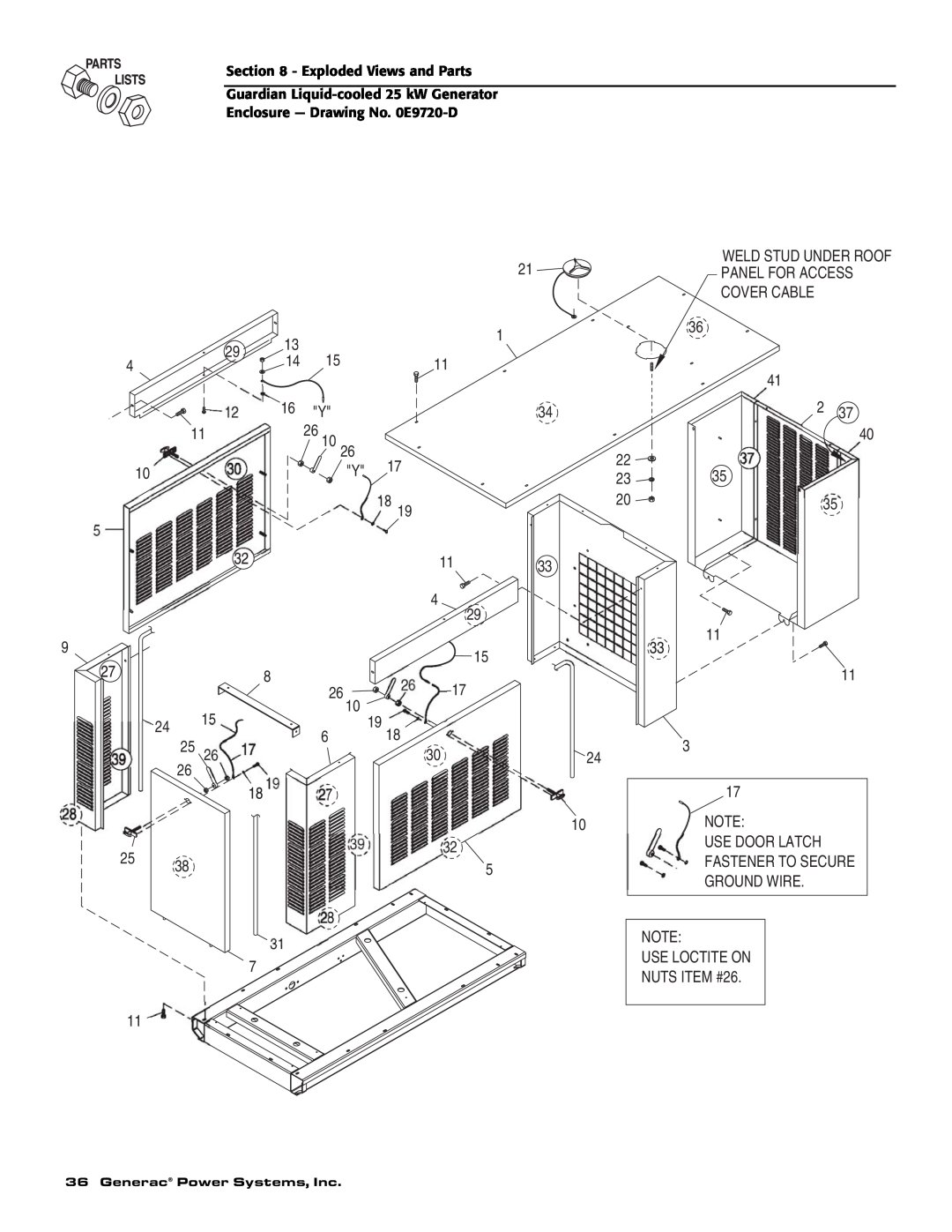

MOUNT

DESCRIPTION

ITEM

PART NO

31 7 11

Enclosure — Drawing No. 0E9720-D

54 36 30

0C2267

40 Generac Power Systems, Inc

0C2267

42 Generac Power Systems, Inc

Engine — Drawing No. 0E9918-E

0E9909

0E1028A I/N

0E8456

LOCKTIGHT

0F1659A

Muffler — Drawing No. 0F2930-B

Stepper Motor — Drawing No. 0E9979-C

Radiator — Drawing No. 0E9965-D

Section 9 — Installation Diagram

Installation Diagram — Drawing No. 0F1020-A

1-800-333-1322

YOUR WARRANTY RIGHTS AND OBLIGATIONS

PURCHASER’S/OWNER’S WARRANTY RESPONSIBILITIES

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

EMISSION CONTROL SYSTEM WARRANTY

EMISSION RELATED PARTS INCLUDE THE FOLLOWING

GENERAC POWER SYSTEMS, INC

WARRANTY SCHEDULE

THIS WARRANTY SHALL NOT APPLY TO THE FOLLOWING

P.O. BOX 297 • WHITEWATER, WI

![]()