1000 specifications

The Genie 1000 is a state-of-the-art aerial work platform designed to provide efficient aerial access solutions for various industrial and construction applications. Renowned for its robust build quality and advanced features, this unit combines functionality with ease of use, making it a favorite among professionals.One of the standout features of the Genie 1000 is its compact design. With a narrow profile, it can easily navigate tight spaces and doorways, making it ideal for indoor and outdoor work environments. Its lightweight structure allows for easy transport between job sites, while still maintaining the strength and stability required for lifting tasks.

The Genie 1000 is equipped with an impressive maximum working height of 30 feet, allowing operators to reach elevated areas safely. Its platform capacity, which can accommodate up to 500 pounds, ensures that multiple workers and tools can be utilized simultaneously, enhancing productivity on the job. The unit also comes with a slide-out platform extension, granting additional reach when needed.

This aerial work platform employs advanced hydraulic technology, ensuring smooth and precise lifting and lowering operations. The Genie 1000 features a user-friendly control system that includes intuitive joystick controls, facilitating easy maneuverability. Safety is paramount, and this model is outfitted with various safety features, including an emergency stop button, guardrails, and a tilt alarm to prevent potential accidents during operation.

Another notable characteristic is its versatile power options. The Genie 1000 can be equipped with various power sources, including electric and diesel engines, depending on the operational requirements. This flexibility enables users to choose between an environmentally friendly electric model for indoor use and a robust diesel version for outdoor applications.

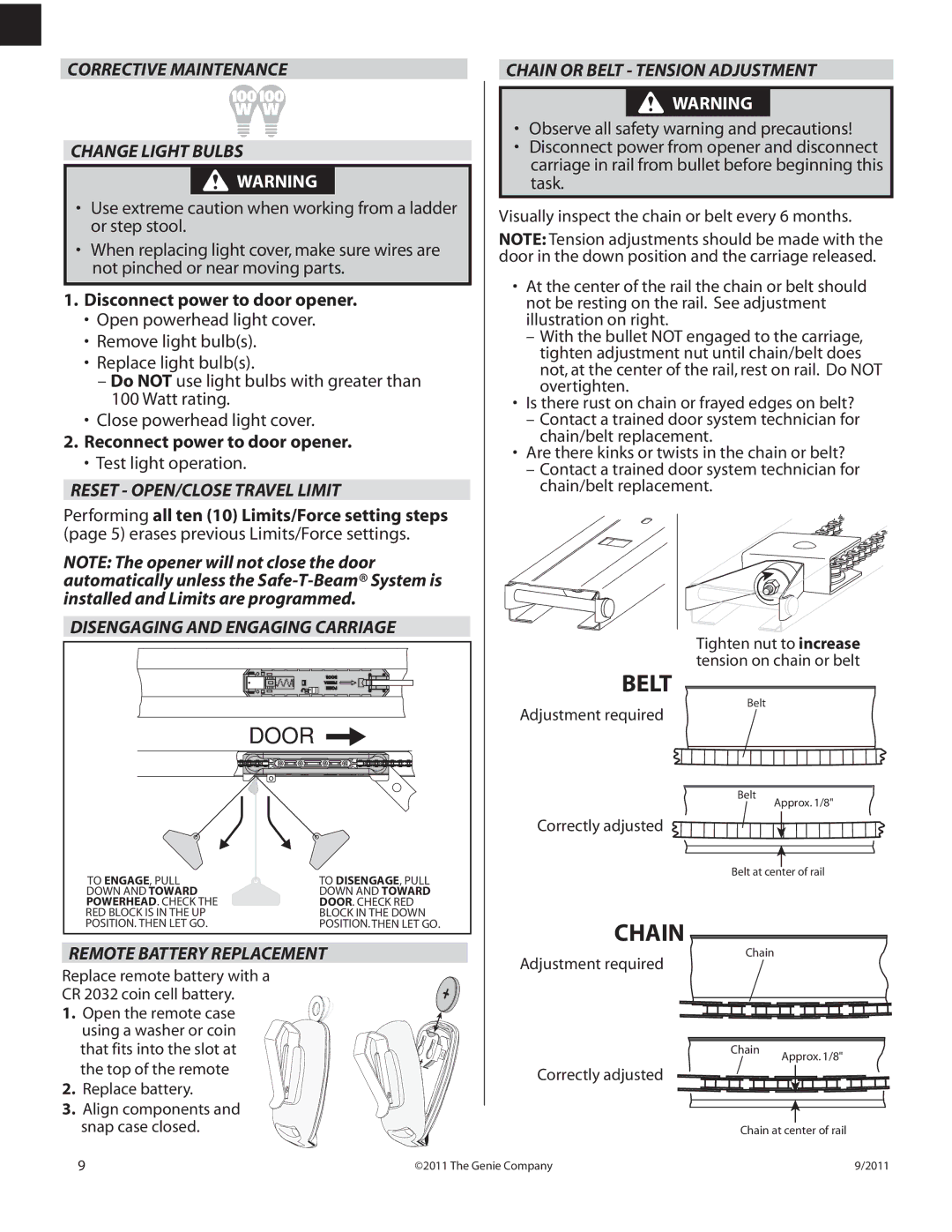

In terms of maintenance, the Genie 1000 is designed with serviceability in mind. Accessible components and clear maintenance points simplify routine checks and repairs, ensuring longevity and reliability.

Overall, the Genie 1000 stands out in the market for its exceptional performance, safety features, and ease of use. Its combination of compactness and capability makes it a vital tool in many industries, setting a new standard for aerial work platforms. Whether in construction, warehouse operations, or facility maintenance, the Genie 1000 is engineered to meet the demands of today’s workforce effectively.