Operator’s Manual | Second Edition • Fourth Printing |

|

|

|

|

Pre-operation Inspection

oBe sure that the operator's, safety and responsibilities manuals are complete, legible and in the storage container located on the mast.

oBe sure that all decals are legible and in place. See Decals section.

oAC & DC models: Check for hydraulic oil leaks and proper oil level. Add oil if needed. See Maintenance section.

oDC models: Check for battery fluid leaks and proper fluid level. Add distilled water if needed. See Maintenance section.

Check the following components or areas for damage, modifications and improperly installed or missing parts:

oElectrical components, wiring and electrical cables

oHydraulic power unit, hoses, fittings and cylinders

oHydraulic manifolds and foot pump

oPlatform entry

oSequencing cables and pulleys

oLifting chains and idler wheels

oMast columns and counterweight

oNuts, bolts and other fasteners

oBreather cap

oFoot pads

oAdjustable glide pads

If equipped: Power wheel assist option

oSteer handle

oHydraulic motor and hoses

If equipped:

oLocking bracket

oHandle and handle lock

oExtension arms

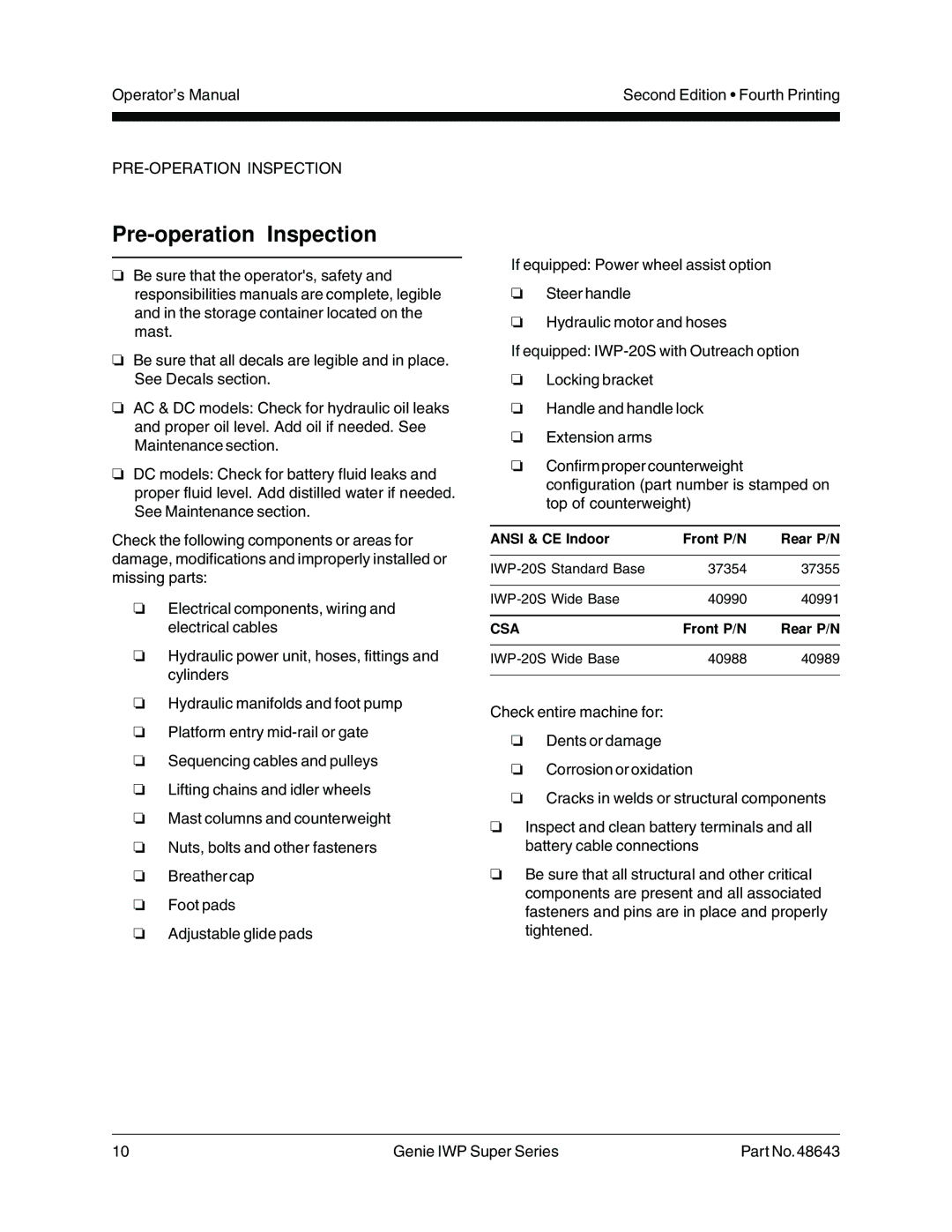

oConfirm proper counterweight configuration (part number is stamped on top of counterweight)

ANSI & CE Indoor | Front P/N | Rear P/N |

|

|

|

37354 | 37355 | |

|

|

|

40990 | 40991 | |

|

|

|

CSA | Front P/N | Rear P/N |

|

|

|

40988 | 40989 | |

|

|

|

Check entire machine for:

oDents or damage

oCorrosion or oxidation

oCracks in welds or structural components

oInspect and clean battery terminals and all battery cable connections

oBe sure that all structural and other critical components are present and all associated fasteners and pins are in place and properly tightened.

10 | Genie IWP Super Series | Part No.48643 |