Operating the tool

Firing mechanism

This tool operates on a single (full sequential actuation) firing system.

Single (full sequential actuation) firing

To fire, grip tool firmly to maintain control, position the contact safety nose (1) of tool onto work surface, and squeeze trigger (4) to fire a fastener. Allow tool to recoil away from work surface as fastener is driven.

This “full sequential actuation” method provides the most accurate fastener placement.

Where to use framing nailer

Framing nailer guns are used mainly in heavy construction applications. Some additional important safety applications are as follows:

1.Fire fasteners into work surface only, never into materials too hard to penetrate such as concrete and steel.

2.Do not drive fasteners on top of other fasteners, or with the tool at too steep an angle as the fasteners may ricochet causing personal injury.

3.Do not drive fasteners close to the edge of the workpiece. The workpiece is likely to split allowing the fastener to fly free or ricochet causing personal injury.

Checking the safety strike element

1.Disconnect the air hose from the framing gun nailer and remove all fasteners from the magazine (7).

2.Make sure the trigger (4) and the contact safety nose (1) move freely up and down.

3.Reconnect air hose to the framing nailer.

Loading & unloading the fasteners

CAUTION. Always disconnect the hose before loading the nailer. Make sure that nails are collated firmly and are not bent. Select nails suitable for your work.

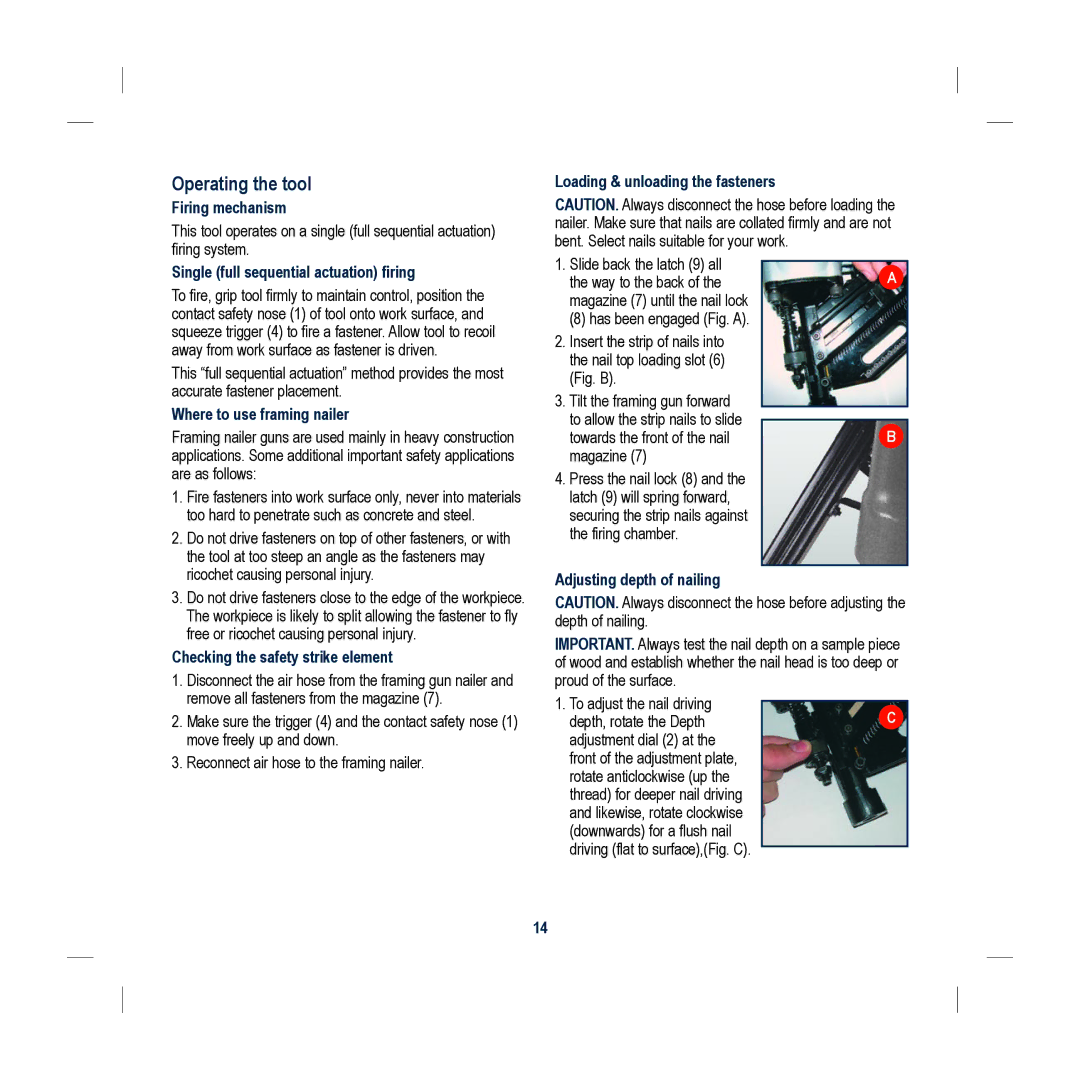

1. Slide back the latch (9) all

the way to the back of theA magazine (7) until the nail lock

(8) has been engaged (Fig. A).

2.Insert the strip of nails into the nail top loading slot (6) (Fig. B).

3.Tilt the framing gun forward to allow the strip nails to slide

towards the front of the nail | B |

magazine (7) |

|

4.Press the nail lock (8) and the latch (9) will spring forward, securing the strip nails against the firing chamber.

Adjusting depth of nailing

CAUTION. Always disconnect the hose before adjusting the depth of nailing.

IMPORTANT. Always test the nail depth on a sample piece of wood and establish whether the nail head is too deep or proud of the surface.

1. To adjust the nail driving

depth, rotate the DepthC adjustment dial (2) at the

front of the adjustment plate, rotate anticlockwise (up the thread) for deeper nail driving and likewise, rotate clockwise (downwards) for a flush nail driving (flat to surface),(Fig. C).

14