ELECTRICAL WIRING

![]() WARNING

WARNING

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVICING OR INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY BE PRESENT. FAILURE TO DO SO MAY CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

Electrical Code. If long wires are required, it may be neces- sary to increase the wire size to prevent excessive voltage drop. Wires should be sized for a maximum of 3% voltage drop.

![]() CAUTION

CAUTION

TO AVOID PROPERTY DAMAGE OR PERSONAL INJURY DUE TO FIRE, USE ONLY COPPER CONDUCTORS.

![]() WARNING

WARNING

HIGH VOLTAGE!

TO AVOID PERSONAL INJURY OR DEATH DUE TO

ELECTRICAL SHOCK, DO NOT TAMPER WITH FACTORY

WIRING. THE INTERNAL POWER AND CONTROL WIRING

OF THESE UNITS ARE

BEEN THOROUGHLY TESTED PRIOR TO SHIPMENT.

CONTACT YOUR LOCAL REPRESENTATIVE IF

ASSISTANCE IS REQUIRED.

![]() CAUTION

CAUTION

TO PREVENT DAMAGE TO THE WIRING, PROTECT WIRING FROM SHARP EDGES. FOLLOW NATIONAL ELECTRICAL CODE AND ALL LOCAL CODES AND ORDINANCES. DO NOT ROUTE WIRES THROUGH REMOVABLE ACCESS PANELS.

![]() CAUTION

CAUTION

CONDUIT AND FITTINGS MUST BE

For unit protection, use a fuse or HACR circuit breaker that is in excess of the circuit ampacity, but less than or equal to the maximum overcurrent protection device. DO NOT EXCEED THE MAXIMUM OVERCURRENT DEVICE SIZE SHOWN ON UNIT DATA PLATE.

All line voltage connections must be made through weather- proof fittings. All exterior power supply and ground wiring must be in approved weatherproof conduit.

The main power supply wiring to the unit and low voltage wiring to accessory controls must be done in accordance with these instructions, the latest edition of the National Electriacl Code (ANSI/NFPA 70), and all local codes and ordinances. All field wiring shall conform with the temperature limitations for Type T wire (63°F/35°C rise).

The main power supply for the CPG036XXX3,4,7 through CPG072 shall be

NOTE: If supply voltage is 208V, lead on primary of trans- former TRANS1 must be moved from the 230V to the 208V tap.

Main power wiring should be sized for the minimum wire ampacity shown on the unit’s database. Size wires in accor- dance with the ampacity tables in Article 310 of the National

![]() CAUTION

CAUTION

TO PREVENT IMPROPER AND DANGEROUS OPERATION DUE TO WIRING ERRORS, LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. VERIFY PROPER OPERATION AFTER SERVICING.

NOTE: A

Ensure the data plate is not covered by the

•Some disconnect switches are not fused. Protect the power leads at the point of distribution in accordance with the unit data plate.

•The unit must be electrically grounded in accordance with local codes or, in the absence of local codes, with the latest edition of the National Electrical Code

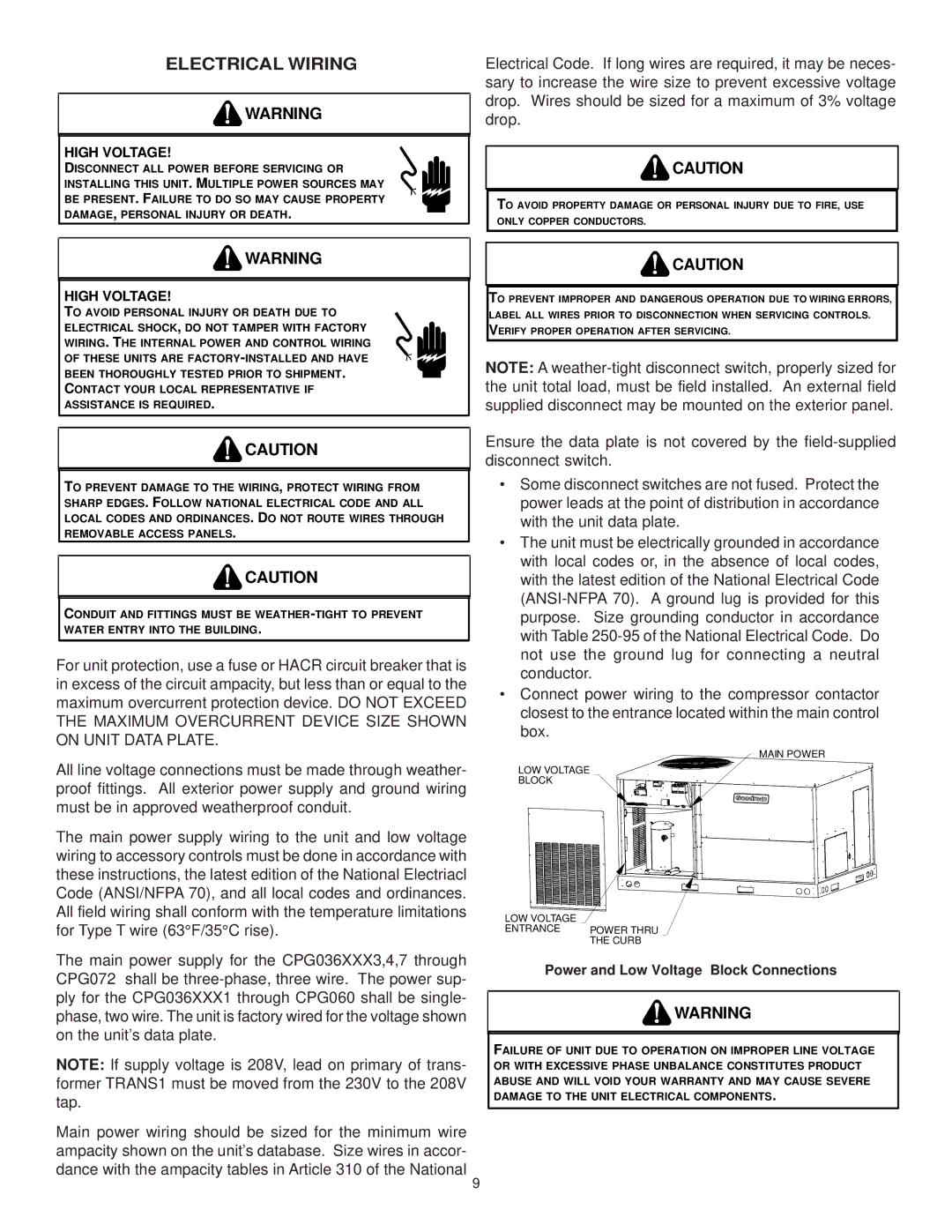

•Connect power wiring to the compressor contactor closest to the entrance located within the main control box.

MAIN POWER

LOW VOLTAGE |

BLOCK |

LOW VOLTAGE

ENTRANCE POWER THRU

THE CURB

Power and Low Voltage Block Connections

![]() WARNING

WARNING

FAILURE OF UNIT DUE TO OPERATION ON IMPROPER LINE VOLTAGE OR WITH EXCESSIVE PHASE UNBALANCE CONSTITUTES PRODUCT ABUSE AND WILL VOID YOUR WARRANTY AND MAY CAUSE SEVERE DAMAGE TO THE UNIT ELECTRICAL COMPONENTS.

9