supply pressure tap is provided on the upstream side of the gas valve. A manifold pressure tap is provided on the gas valve. The normal manifold pressure for full input is 3.5" w.c. on natural gas and 9.5" w.c. for propane gas. Low fire natu- ral gas 2.0” w.c., 6.0” low fire propane gas. Minimum gas supply pressure is 5.5" w.c. for natural gas and 11.0" for pro- pane gas. In order to obtain rating, gas supply pressure must be 11.0" w.c. for propane gas.

The pressure regulator on LP gas models is adjusted for 9.5" w.c. manifold pressure and is intended to prevent

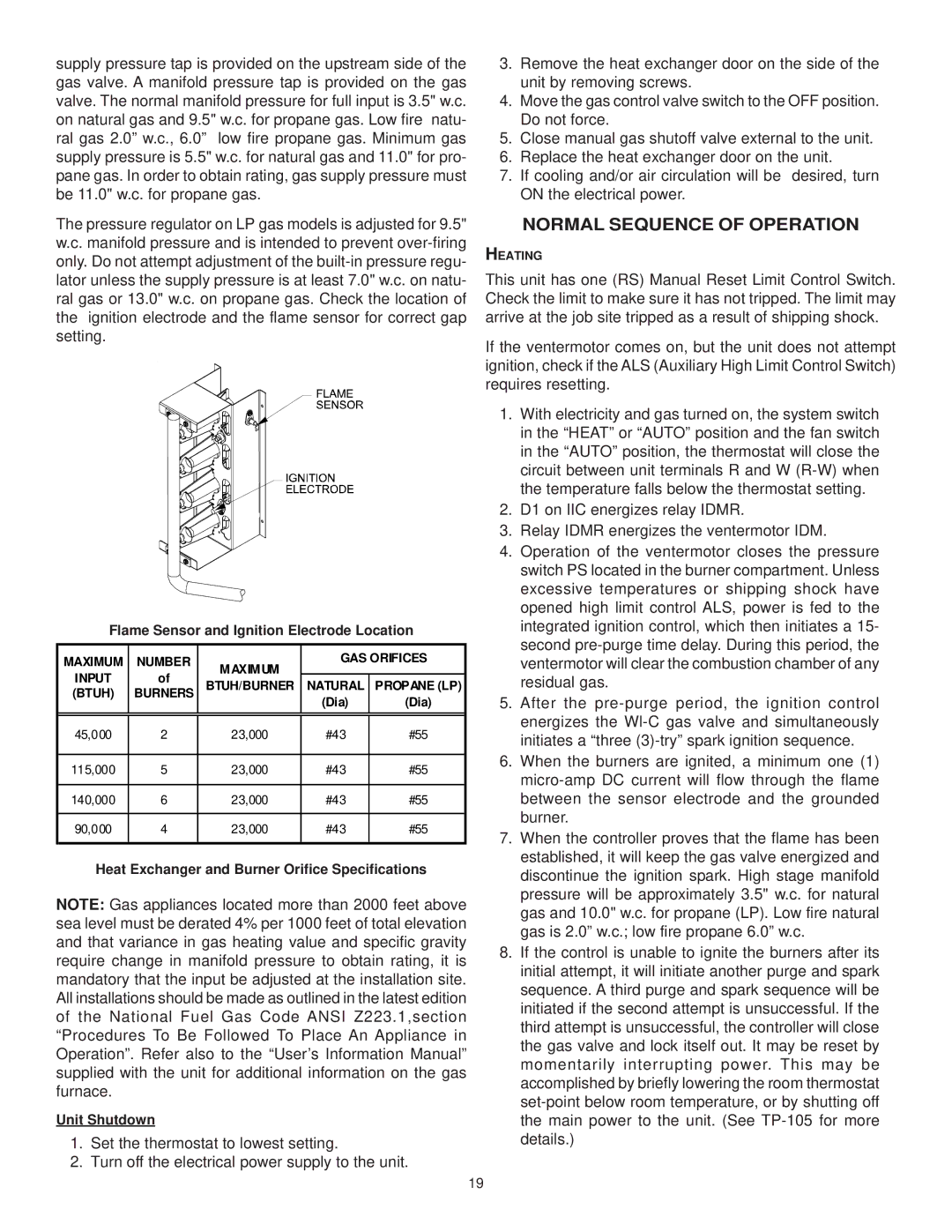

Flame Sensor and Ignition Electrode Location

MAXIMUM | NUMBER | MAXIMUM | GAS ORIFICES | ||

INPUT | of |

|

| ||

BTUH/BURNER | NATURAL | PROPANE (LP) | |||

(BTUH) | BURNERS | ||||

|

|

| (Dia) | (Dia) | |

|

|

|

|

| |

45,000 | 2 | 23,000 | #43 | #55 | |

|

|

|

|

| |

115,000 | 5 | 23,000 | #43 | #55 | |

|

|

|

|

| |

140,000 | 6 | 23,000 | #43 | #55 | |

|

|

|

|

| |

90,000 | 4 | 23,000 | #43 | #55 | |

|

|

|

|

| |

Heat Exchanger and Burner Orifice Specifications

NOTE: Gas appliances located more than 2000 feet above sea level must be derated 4% per 1000 feet of total elevation and that variance in gas heating value and specific gravity require change in manifold pressure to obtain rating, it is mandatory that the input be adjusted at the installation site. All installations should be made as outlined in the latest edition of the National Fuel Gas Code ANSI Z223.1,section “Procedures To Be Followed To Place An Appliance in Operation”. Refer also to the “User’s Information Manual” supplied with the unit for additional information on the gas furnace.

Unit Shutdown

1.Set the thermostat to lowest setting.

2.Turn off the electrical power supply to the unit.

3.Remove the heat exchanger door on the side of the unit by removing screws.

4.Move the gas control valve switch to the OFF position. Do not force.

5.Close manual gas shutoff valve external to the unit.

6.Replace the heat exchanger door on the unit.

7.If cooling and/or air circulation will be desired, turn ON the electrical power.

NORMAL SEQUENCE OF OPERATION

HEATING

This unit has one (RS) Manual Reset Limit Control Switch. Check the limit to make sure it has not tripped. The limit may arrive at the job site tripped as a result of shipping shock.

If the ventermotor comes on, but the unit does not attempt ignition, check if the ALS (Auxiliary High Limit Control Switch) requires resetting.

1.With electricity and gas turned on, the system switch in the “HEAT” or “AUTO” position and the fan switch in the “AUTO” position, the thermostat will close the circuit between unit terminals R and W

2.D1 on IIC energizes relay IDMR.

3.Relay IDMR energizes the ventermotor IDM.

4.Operation of the ventermotor closes the pressure switch PS located in the burner compartment. Unless excessive temperatures or shipping shock have opened high limit control ALS, power is fed to the integrated ignition control, which then initiates a 15- second

5.After the

6.When the burners are ignited, a minimum one (1)

7.When the controller proves that the flame has been established, it will keep the gas valve energized and discontinue the ignition spark. High stage manifold pressure will be approximately 3.5" w.c. for natural gas and 10.0" w.c. for propane (LP). Low fire natural gas is 2.0” w.c.; low fire propane 6.0” w.c.

8.If the control is unable to ignite the burners after its initial attempt, it will initiate another purge and spark sequence. A third purge and spark sequence will be initiated if the second attempt is unsuccessful. If the third attempt is unsuccessful, the controller will close the gas valve and lock itself out. It may be reset by momentarily interrupting power. This may be accomplished by briefly lowering the room thermostat

19