Troubleshooting the Air Motor

Preventive Maintenance Schedule

The operating conditions of your particular system determine how often maintenance is required. Estab- lish a preventive maintenance schedule by recording when and what kind of maintenance is needed, and then determine a regular schedule for checking your system.

Air Motor Cylinder

Premier motors require lubrication and continuous maintenance including the replacement of the air motor cylinder casting at least every 15,000,000 cycles of use. Use Premier cylinder repair kit 16P239.

Repair or replace the Air Valve assembly (222799) whenever motor stalling or hesitation occurs. This ensures the motor does not overtravel and cause added stress to the cylinder casting.

![]() WARNING

WARNING

EXPLOSION HAZARD

Without proper maintenance, the cylin- der casting (120026) may fracture unexpectedly due to metal fatigue. This is a potentially hazardous condition and may result in serious injury. The precise life of this casting is difficult to predict

and is affected by the operating pressure, number of cycles, lubrication and air valve maintenance.

Checking the Air Motor for Leaks or Damaged Parts

If the pump is not performing well, the problem could be in the air motor. To check the air motor, perform the following steps.

1.Close the

2.Remove the shroud. Refer to page 11.

3.Reinstall the air inlet fitting (22). Reconnect the air line.

4.Open the

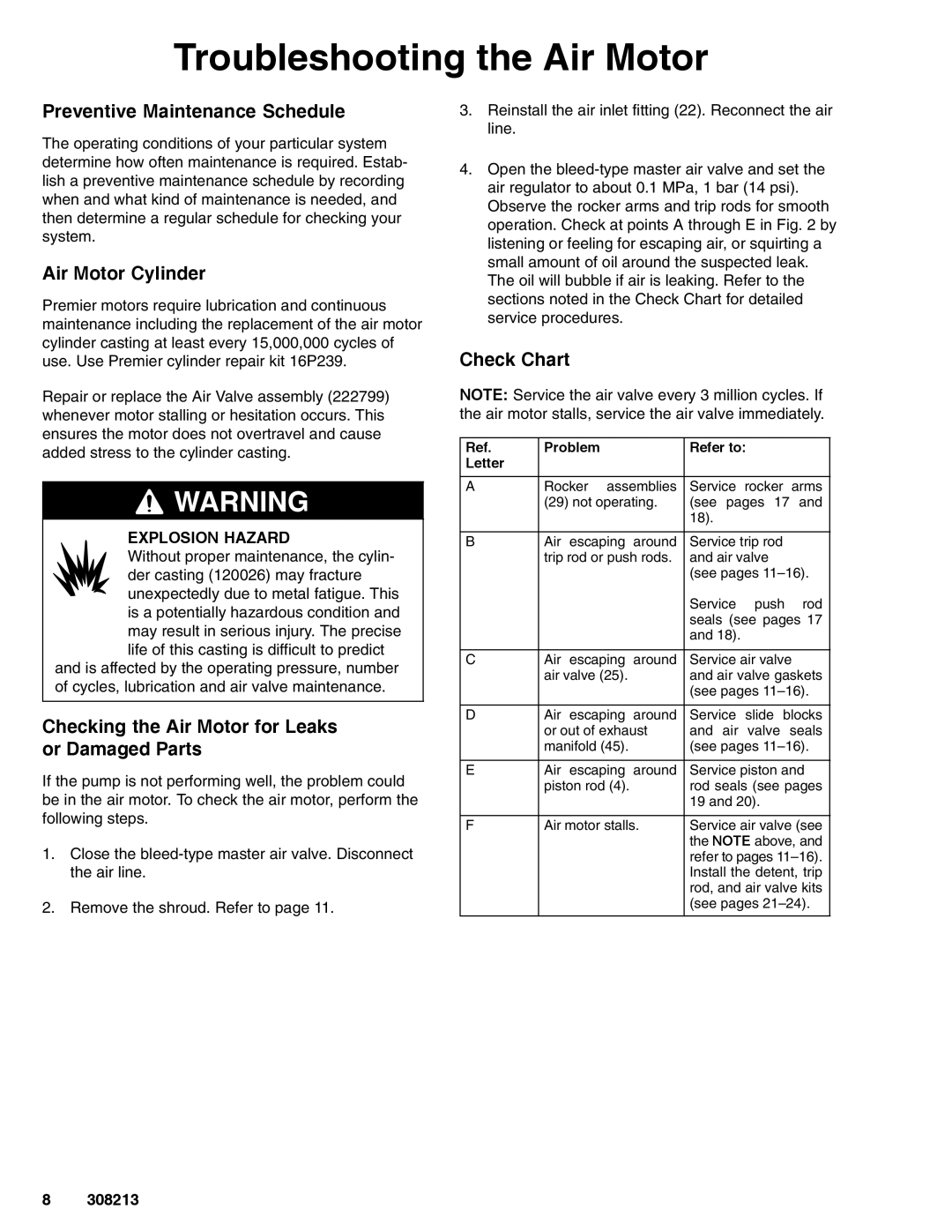

Check Chart

NOTE: Service the air valve every 3 million cycles. If the air motor stalls, service the air valve immediately.

Ref. | Problem |

| Refer to: |

| |

Letter |

|

|

|

|

|

|

|

|

|

| |

A | Rocker assemblies | Service | rocker | arms | |

| (29) not operating. | (see pages 17 | and | ||

|

|

| 18). |

|

|

|

|

|

|

| |

B | Air escaping | around | Service trip rod |

| |

| trip rod or push rods. | and air valve |

| ||

|

|

| (see pages | ||

|

|

| Service | push | rod |

|

|

| seals (see pages 17 | ||

|

|

| and 18). |

|

|

|

|

|

| ||

C | Air escaping | around | Service air valve | ||

| air valve (25). |

| and air valve gaskets | ||

|

|

| (see pages | ||

|

|

|

|

| |

D | Air escaping | around | Service | slide blocks | |

| or out of exhaust | and air | valve | seals | |

| manifold (45). |

| (see pages | ||

|

|

|

| ||

E | Air escaping | around | Service piston and | ||

| piston rod (4). |

| rod seals (see pages | ||

|

|

| 19 and 20). |

| |

|

|

| |||

F | Air motor stalls. | Service air valve (see | |||

|

|

| the NOTE above, and | ||

|

|

| refer to pages | ||

|

|

| Install the detent, trip | ||

|

|

| rod, and air valve kits | ||

|

|

| (see pages | ||

|

|

|

|

|

|

8 308213