Installation

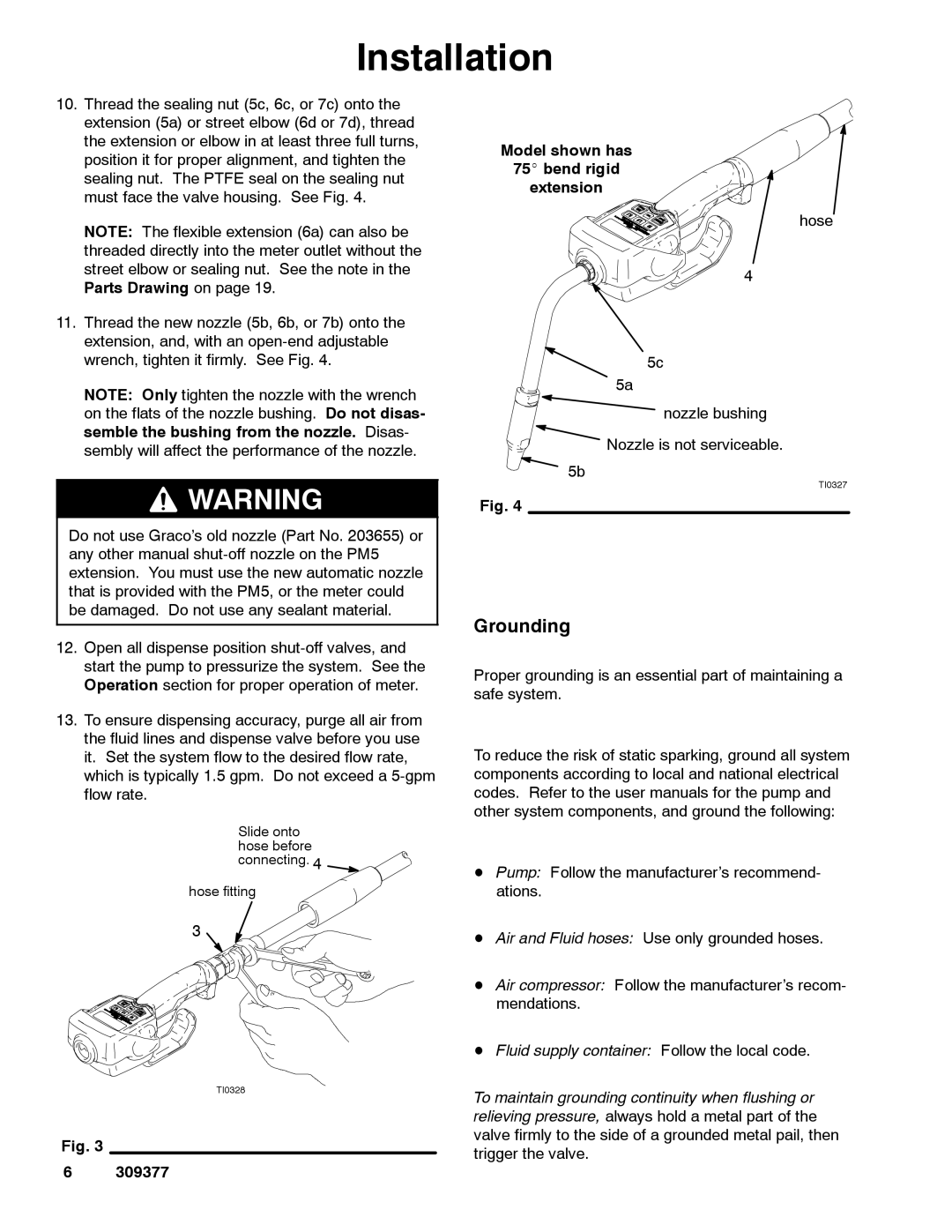

10.Thread the sealing nut (5c, 6c, or 7c) onto the extension (5a) or street elbow (6d or 7d), thread the extension or elbow in at least three full turns, position it for proper alignment, and tighten the sealing nut. The PTFE seal on the sealing nut must face the valve housing. See Fig. 4.

NOTE: The flexible extension (6a) can also be threaded directly into the meter outlet without the street elbow or sealing nut. See the note in the Parts Drawing on page 19.

11.Thread the new nozzle (5b, 6b, or 7b) onto the extension, and, with an

NOTE: Only tighten the nozzle with the wrench on the flats of the nozzle bushing. Do not disas- semble the bushing from the nozzle. Disas- sembly will affect the performance of the nozzle.

![]() WARNING

WARNING

Do not use Graco’s old nozzle (Part No. 203655) or any other manual

12.Open all dispense position

13.To ensure dispensing accuracy, purge all air from the fluid lines and dispense valve before you use it. Set the system flow to the desired flow rate, which is typically 1.5 gpm. Do not exceed a

Slide onto hose before connecting. 4

hose fitting

3

TI0328

Fig. 3

6 309377

Model shown has

75_ bend rigid

extension

hose

4

5c

5a

nozzle bushing

Nozzle is not serviceable.

5b

TI0327

Fig. 4

Grounding

Proper grounding is an essential part of maintaining a safe system.

To reduce the risk of static sparking, ground all system components according to local and national electrical codes. Refer to the user manuals for the pump and other system components, and ground the following:

DPump: Follow the manufacturer’s recommend- ations.

DAir and Fluid hoses: Use only grounded hoses.

DAir compressor: Follow the manufacturer’s recom- mendations.

DFluid supply container: Follow the local code.

To maintain grounding continuity when flushing or relieving pressure, always hold a metal part of the valve firmly to the side of a grounded metal pail, then trigger the valve.