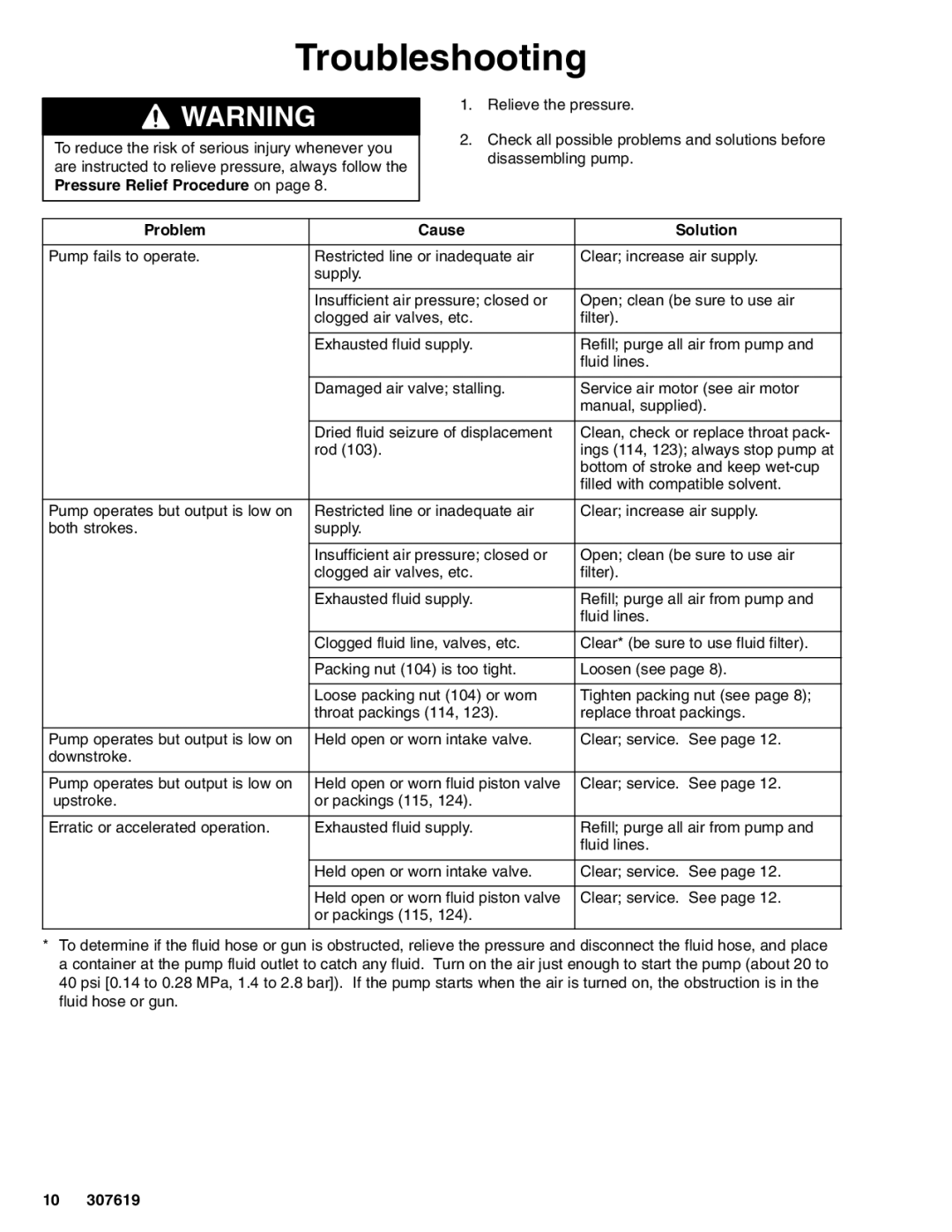

Troubleshooting

![]() WARNING

WARNING

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the Pressure Relief Procedure on page 8.

1.Relieve the pressure.

2.Check all possible problems and solutions before disassembling pump.

Problem | Cause | Solution |

|

|

|

Pump fails to operate. | Restricted line or inadequate air | Clear; increase air supply. |

| supply. |

|

|

|

|

| Insufficient air pressure; closed or | Open; clean (be sure to use air |

| clogged air valves, etc. | filter). |

|

|

|

| Exhausted fluid supply. | Refill; purge all air from pump and |

|

| fluid lines. |

|

|

|

| Damaged air valve; stalling. | Service air motor (see air motor |

|

| manual, supplied). |

|

|

|

| Dried fluid seizure of displacement | Clean, check or replace throat pack- |

| rod (103). | ings (114, 123); always stop pump at |

|

| bottom of stroke and keep |

|

| filled with compatible solvent. |

|

|

|

Pump operates but output is low on | Restricted line or inadequate air | Clear; increase air supply. |

both strokes. | supply. |

|

|

|

|

| Insufficient air pressure; closed or | Open; clean (be sure to use air |

| clogged air valves, etc. | filter). |

|

|

|

| Exhausted fluid supply. | Refill; purge all air from pump and |

|

| fluid lines. |

|

|

|

| Clogged fluid line, valves, etc. | Clear* (be sure to use fluid filter). |

|

|

|

| Packing nut (104) is too tight. | Loosen (see page 8). |

|

|

|

| Loose packing nut (104) or worn | Tighten packing nut (see page 8); |

| throat packings (114, 123). | replace throat packings. |

|

|

|

Pump operates but output is low on | Held open or worn intake valve. | Clear; service. See page 12. |

downstroke. |

|

|

|

|

|

Pump operates but output is low on | Held open or worn fluid piston valve | Clear; service. See page 12. |

upstroke. | or packings (115, 124). |

|

|

|

|

Erratic or accelerated operation. | Exhausted fluid supply. | Refill; purge all air from pump and |

|

| fluid lines. |

|

|

|

| Held open or worn intake valve. | Clear; service. See page 12. |

|

|

|

| Held open or worn fluid piston valve | Clear; service. See page 12. |

| or packings (115, 124). |

|

|

|

|

*To determine if the fluid hose or gun is obstructed, relieve the pressure and disconnect the fluid hose, and place a container at the pump fluid outlet to catch any fluid. Turn on the air just enough to start the pump (about 20 to 40 psi [0.14 to 0.28 MPa, 1.4 to 2.8 bar]). If the pump starts when the air is turned on, the obstruction is in the fluid hose or gun.

10 307619