Contents

Instructions - Parts List

CARBON STEEL

Part No. 222828 Pump, Series A

Part No. 246935 Pump, Series A

Table of Contents

Symbols

Warning Symbol

Caution Symbol

EQUIPMENT MISUSE HAZARD

SKIN INJECTION HAZARD

MOVING PARTS HAZARD

FIRE AND EXPLOSION HAZARD

TOXIC FLUID HAZARD

Page

Installation

Grounding

AIR-POWEREDPUMPS

Installation

SYSTEM ACCESSORIES

Mounting Accessories

Air Line Accessories

Fluid Line Accessories

HYDRAULIC-POWEREDPUMPS

Installation

Filters

Hydraulic Lines

Hydraulic Motor Drip Pan

Fluid Supply Hoses

ALL MODELS Pressure Relief Procedure

AIR-POWEREDMODELS Starting and Adjusting the Pump

Operation

Packing Nut/Wet-Cup

AIR-POWEREDMODELS

Shutdown and Care of the Pump

Model 222835 Shown

Operation

HYDRAULIC-POWEREDMODELS

Starting and Adjusting the Pump

Operation

Shutdown and Care of the Pump

CAUSE

Troubleshooting

SOLUTION

Required Tools

Service

Disconnecting the Displacement Pump

Service

King, Bulldog, and

Premier Pumps

Viscount Pumps

Reconnecting the Displacement Pump

Service

Displacement Pump Disassembly

Service

INTAKE CHECK VALVE

308149

Service

Service

4Remove and clean plug

THROAT PACKING DETAIL

DETAIL OF PISTON CHECK VALVE

Reassembly

Service

Service

THROAT PACKING DETAIL

DETAIL OF

PISTON CHECK VALVE

Service

Parts

Model 222828 Pump, Series A

Model 222829 Pump, Series A

Model 246935 Pump, Series A

Model 222835 Pump, Series B

Model 222901 Pump, Series B

Model 246936 Pump, Series A

24 1 Ratio, with Quiet King Air Motor

Parts

222800

Displacement Pump

Model 222810, Series B Model 246934, Series A

Parts

0919A

PTFE Packing Conversion Kit

Leather Packing Conversion Kit

Ink Pump Conversion Kit

Displacement Pump

Technical Data

Model 222828 and 246935 Bulldog Pump

Model 222829 Quiet Bulldog Pump

Technical Data

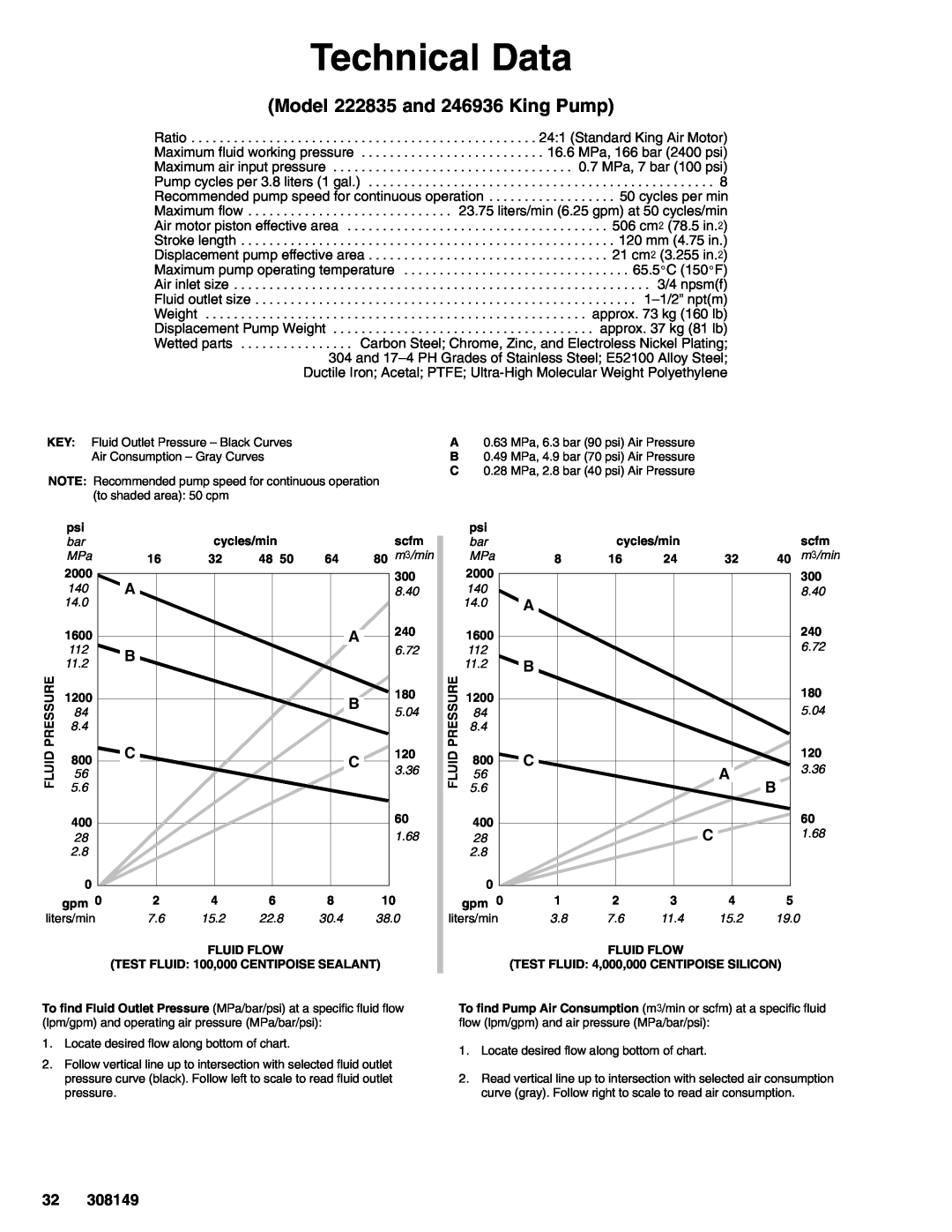

Model 222835 and 246936 King Pump

Technical Data

Model 222901 Quiet King Pump

Technical Data

Model 222940 Premier Pump

Technical Data

Model 222902 and 246937 Viscount Pump

Technical Data

liters/min

liters/min

Dimensions

Model 222835 Shown

B A E C D

Pump Model

Premier Pumps

Mounting Hole Layouts

Bulldog, King, and Viscount Pumps

Graco Standard Warranty

Graco Information

FOR GRACO CANADA CUSTOMERS

Graco Headquarters Minneapolis