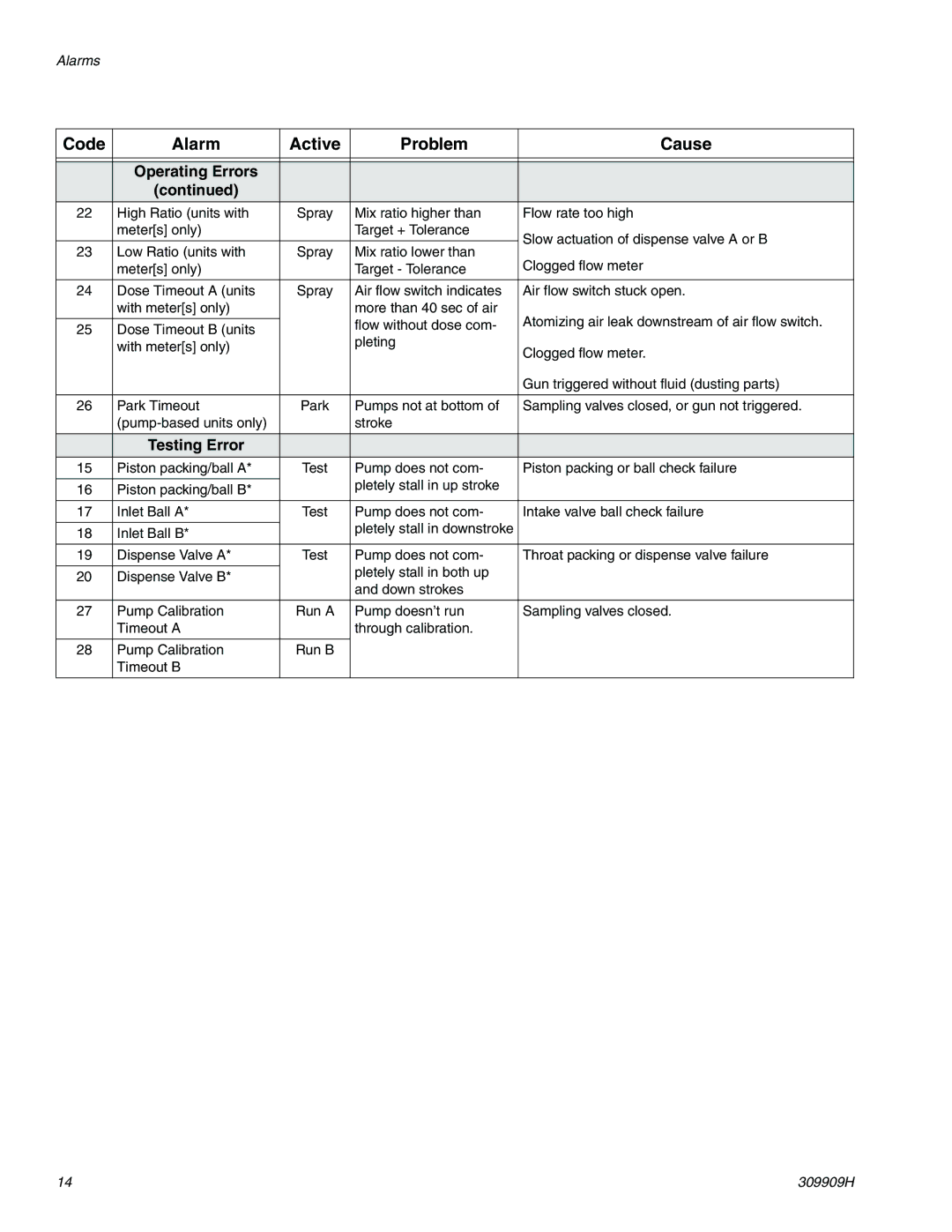

Alarms

Code | Alarm | Active | Problem | Cause | |

|

|

|

|

| |

|

|

|

|

| |

| Operating Errors |

|

|

| |

| (continued) |

|

|

| |

22 | High Ratio (units with | Spray | Mix ratio higher than | Flow rate too high | |

| meter[s] only) |

| Target + Tolerance | Slow actuation of dispense valve A or B | |

|

|

|

| ||

23 | Low Ratio (units with | Spray | Mix ratio lower than | ||

Clogged flow meter | |||||

| meter[s] only) |

| Target - Tolerance | ||

|

|

|

|

| |

24 | Dose Timeout A (units | Spray | Air flow switch indicates | Air flow switch stuck open. | |

| with meter[s] only) |

| more than 40 sec of air | Atomizing air leak downstream of air flow switch. | |

|

|

| flow without dose com- | ||

25 | Dose Timeout B (units |

| |||

| pleting |

| |||

| with meter[s] only) |

| Clogged flow meter. | ||

|

|

| |||

|

|

|

| ||

|

|

|

| Gun triggered without fluid (dusting parts) | |

|

|

|

|

| |

26 | Park Timeout | Park | Pumps not at bottom of | Sampling valves closed, or gun not triggered. | |

|

| stroke |

| ||

|

|

|

|

| |

| Testing Error |

|

|

| |

15 | Piston packing/ball A* | Test | Pump does not com- | Piston packing or ball check failure | |

|

|

| pletely stall in up stroke |

| |

16 | Piston packing/ball B* |

|

| ||

|

|

| |||

|

|

|

|

| |

17 | Inlet Ball A* | Test | Pump does not com- | Intake valve ball check failure | |

|

|

| pletely stall in downstroke |

| |

18 | Inlet Ball B* |

|

| ||

|

|

| |||

|

|

|

|

| |

19 | Dispense Valve A* | Test | Pump does not com- | Throat packing or dispense valve failure | |

|

|

| pletely stall in both up |

| |

20 | Dispense Valve B* |

|

| ||

| and down strokes |

| |||

|

|

|

| ||

|

|

|

|

| |

27 | Pump Calibration | Run A | Pump doesn’t run | Sampling valves closed. | |

| Timeout A |

| through calibration. |

| |

|

|

|

|

| |

28 | Pump Calibration | Run B |

|

| |

| Timeout B |

|

|

| |

|

|

|

|

|

14 | 309909H |