Repair

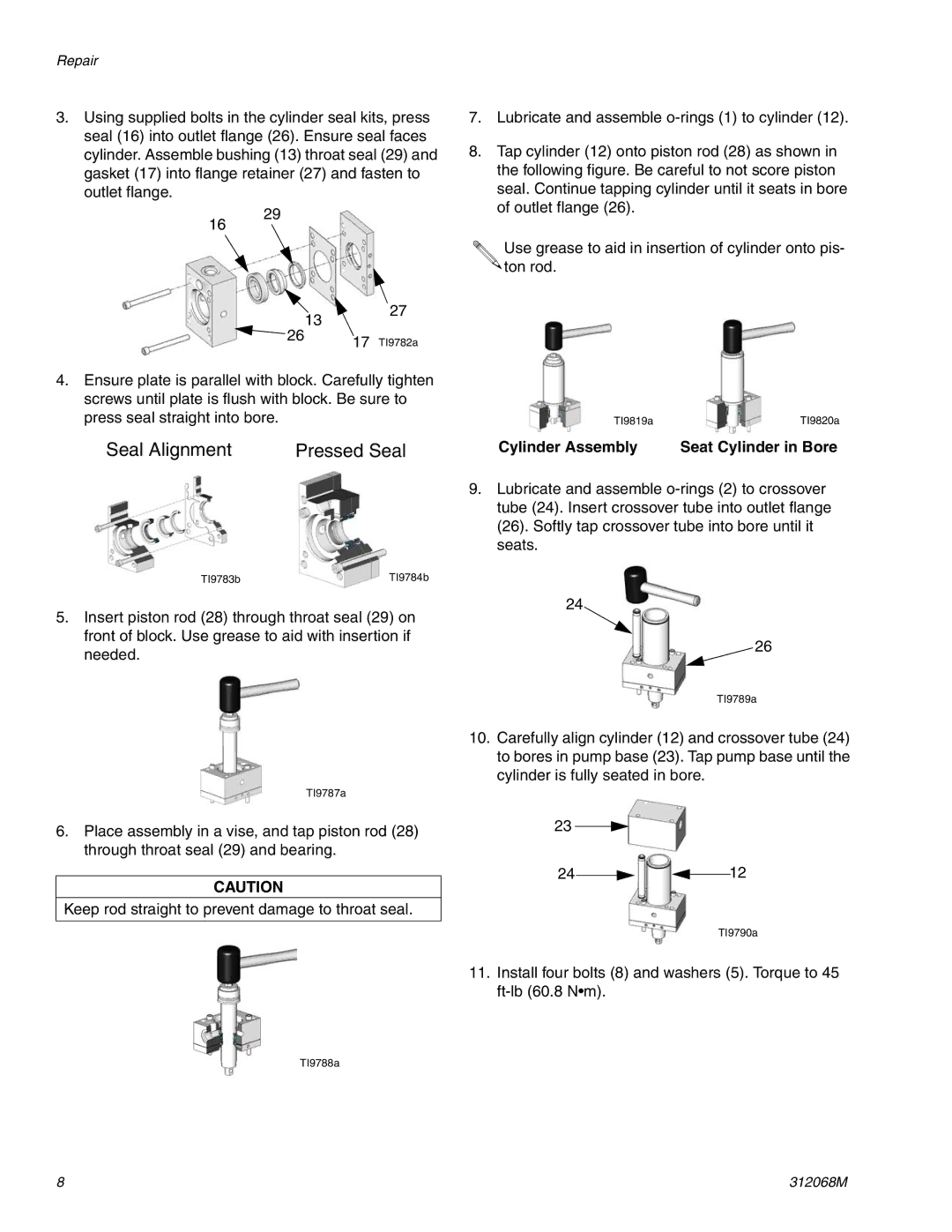

3.Using supplied bolts in the cylinder seal kits, press seal (16) into outlet flange (26). Ensure seal faces cylinder. Assemble bushing (13) throat seal (29) and gasket (17) into flange retainer (27) and fasten to outlet flange.

7. | Lubricate and assemble |

8. | Tap cylinder (12) onto piston rod (28) as shown in |

| the following figure. Be careful to not score piston |

| seal. Continue tapping cylinder until it seats in bore |

| of outlet flange (26). |

16

29

Use grease to aid in insertion of cylinder onto pis- ![]()

![]() ton rod.

ton rod.

| 13 | 27 | |

26 |

| ||

17 | TI9782a | ||

|

4.Ensure plate is parallel with block. Carefully tighten screws until plate is flush with block. Be sure to press seal straight into bore.

Seal Alignment | Pressed Seal |

TI9819a | TI9820a |

Cylinder Assembly | Seat Cylinder in Bore |

TI9783b | TI9784b |

5.Insert piston rod (28) through throat seal (29) on front of block. Use grease to aid with insertion if needed.

TI9787a

6.Place assembly in a vise, and tap piston rod (28) through throat seal (29) and bearing.

CAUTION

Keep rod straight to prevent damage to throat seal.

TI9788a

9.Lubricate and assemble

24

26

TI9789a

10.Carefully align cylinder (12) and crossover tube (24) to bores in pump base (23). Tap pump base until the cylinder is fully seated in bore.

23

24![]()

![]()

![]() 12

12

TI9790a

11.Install four bolts (8) and washers (5). Torque to 45

8 | 312068M |