Piston and Cylinder Seals

Piston Seal and Cylinder Seal Repair Kits are avail- ![]()

![]() able. See Table 1 on page 17 to order the correct kits for your pump. Also see kit manual 312071.

able. See Table 1 on page 17 to order the correct kits for your pump. Also see kit manual 312071.

Repair

Reassembly

CAUTION

To prevent

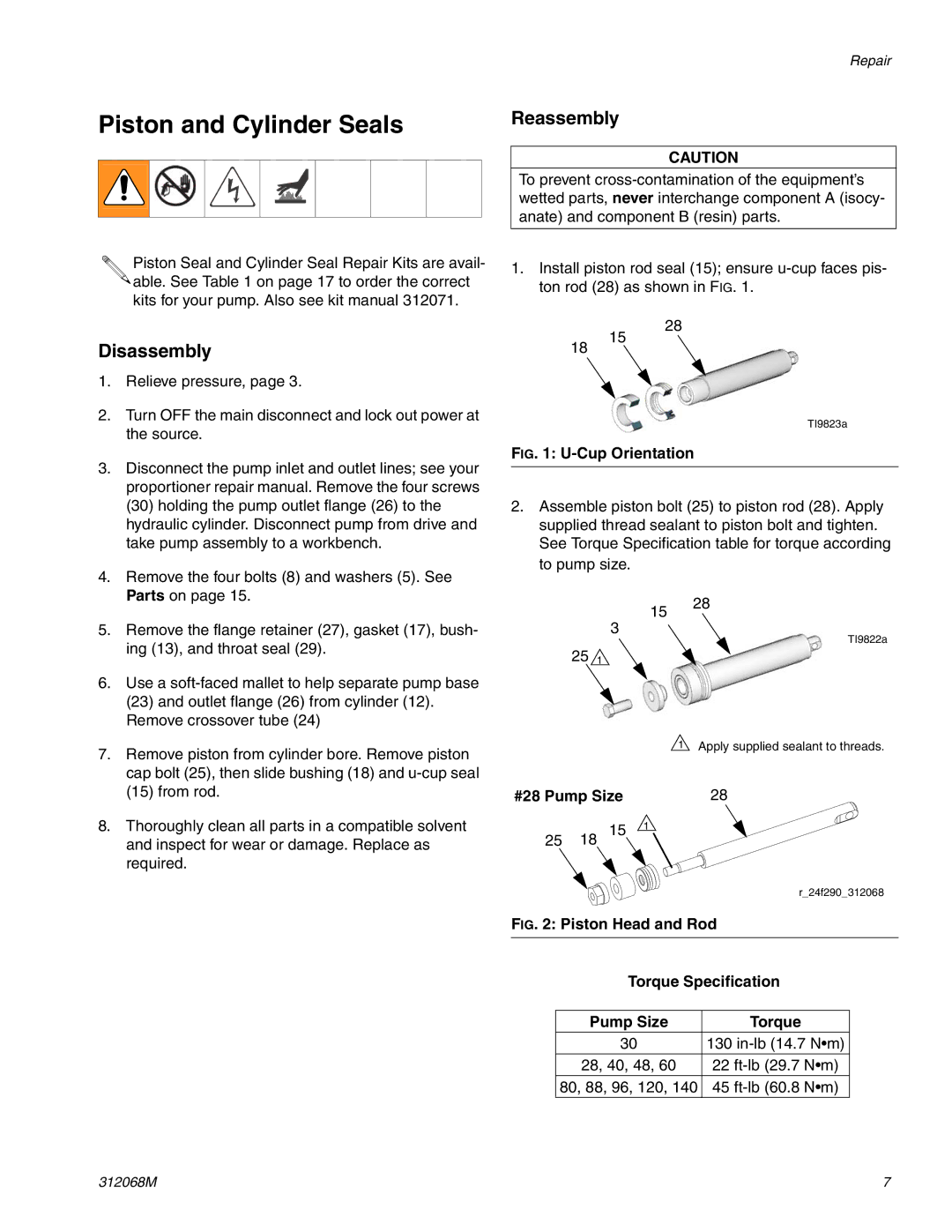

1.Install piston rod seal (15); ensure

Disassembly

1. | Relieve pressure, page 3. |

2. | Turn OFF the main disconnect and lock out power at |

| the source. |

18

28

15

TI9823a

3. | Disconnect the pump inlet and outlet lines; see your |

| proportioner repair manual. Remove the four screws |

| (30) holding the pump outlet flange (26) to the |

| hydraulic cylinder. Disconnect pump from drive and |

| take pump assembly to a workbench. |

4. | Remove the four bolts (8) and washers (5). See |

| Parts on page 15. |

5. | Remove the flange retainer (27), gasket (17), bush- |

| ing (13), and throat seal (29). |

6. | Use a |

| (23) and outlet flange (26) from cylinder (12). |

| Remove crossover tube (24) |

7. | Remove piston from cylinder bore. Remove piston |

| cap bolt (25), then slide bushing (18) and |

| (15) from rod. |

FIG. 1: U-Cup Orientation

2.Assemble piston bolt (25) to piston rod (28). Apply supplied thread sealant to piston bolt and tighten. See Torque Specification table for torque according to pump size.

15 | 28 |

| |

3 | TI9822a |

| |

25 1 |

|

![]() 1 Apply supplied sealant to threads.

1 Apply supplied sealant to threads.

#28 Pump Size | 28 |

8. Thoroughly clean all parts in a compatible solvent |

and inspect for wear or damage. Replace as |

required. |

25 18

15 1

r_24f290_312068

FIG. 2: Piston Head and Rod

Torque Specification

Pump Size | Torque |

30 | 130 |

28, 40, 48, 60 | 22 |

80, 88, 96, 120, 140 | 45 |

312068M | 7 |