Maintenance

Torque Instructions

NOTE: All fasteners for the fluid covers, center diaphragm joint, and manifolds have a

If fluid cover, center diaphragm joint, or manifold fasteners have been loosened, it is important to torque them using the following procedure to improve sealing.

NOTE: Always completely torque the fluid covers and center diaphragm joint before torquing the manifolds.

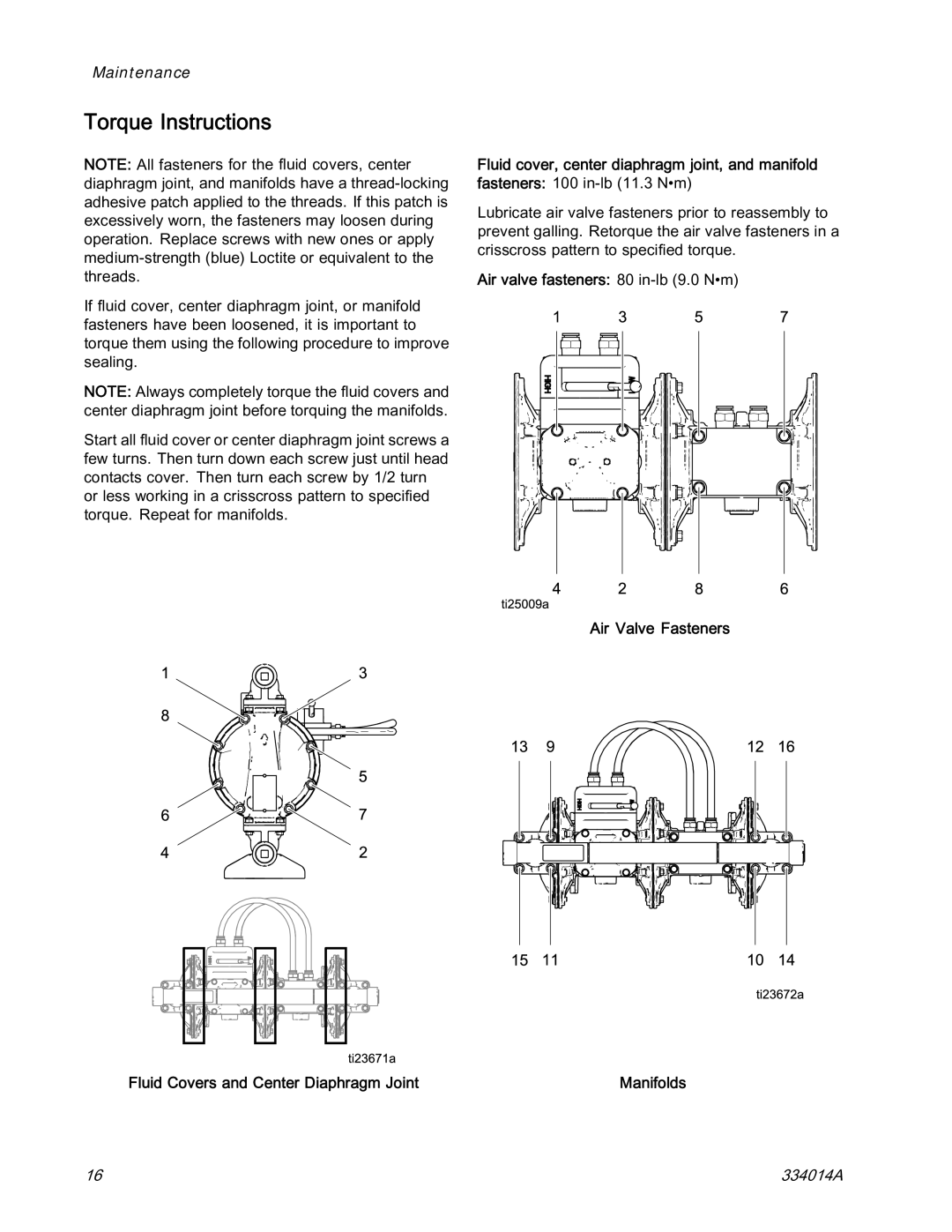

Start all fluid cover or center diaphragm joint screws a few turns. Then turn down each screw just until head contacts cover. Then turn each screw by 1/2 turn or less working in a crisscross pattern to specified torque. Repeat for manifolds.

Fluid cover, center diaphragm joint, and manifold fasteners: 100

Lubricate air valve fasteners prior to reassembly to prevent galling. Retorque the air valve fasteners in a crisscross pattern to specified torque.

Air valve fasteners: 80

Air Valve Fasteners

Fluid Covers and Center Diaphragm Joint | Manifolds |

16 | 334014A |