PT2500 specifications

The Graco PT2500 is a powerful and versatile paint sprayer designed for both professional contractors and DIY enthusiasts looking for a reliable tool for their painting projects. With a robust construction and advanced technologies, the PT2500 stands out in the market for its efficiency and performance.One of the main features of the Graco PT2500 is its high output capacity. This paint sprayer is equipped with a powerful motor that can deliver consistent pressure, allowing for smooth and even application of paint, stains, and varnishes. It is capable of handling a wide variety of coatings, making it suitable for both interior and exterior projects.

Additionally, the PT2500 features Graco’s ProConnect system, which allows for easy pump replacement without the need for tools. This system minimizes downtime and ensures that users can get back to their projects quickly, making it an ideal choice for professionals who need to maintain productivity on the job site.

The PT2500 incorporates advanced RAC X SwitchTip technology. This innovative feature enables users to reverse the tip for quick unclogging, which saves time and ensures a continuous workflow. The switchable tips also allow for various spray patterns, accommodating different project requirements with ease.

Another notable characteristic is the lightweight and portable design of the Graco PT2500. Weighing less than many competitors in its class, this sprayer can be easily transported and maneuvered around the job site or within the home. The included cart provides stability and allows for easy movement, making it ideal for larger projects or jobs that require accessibility.

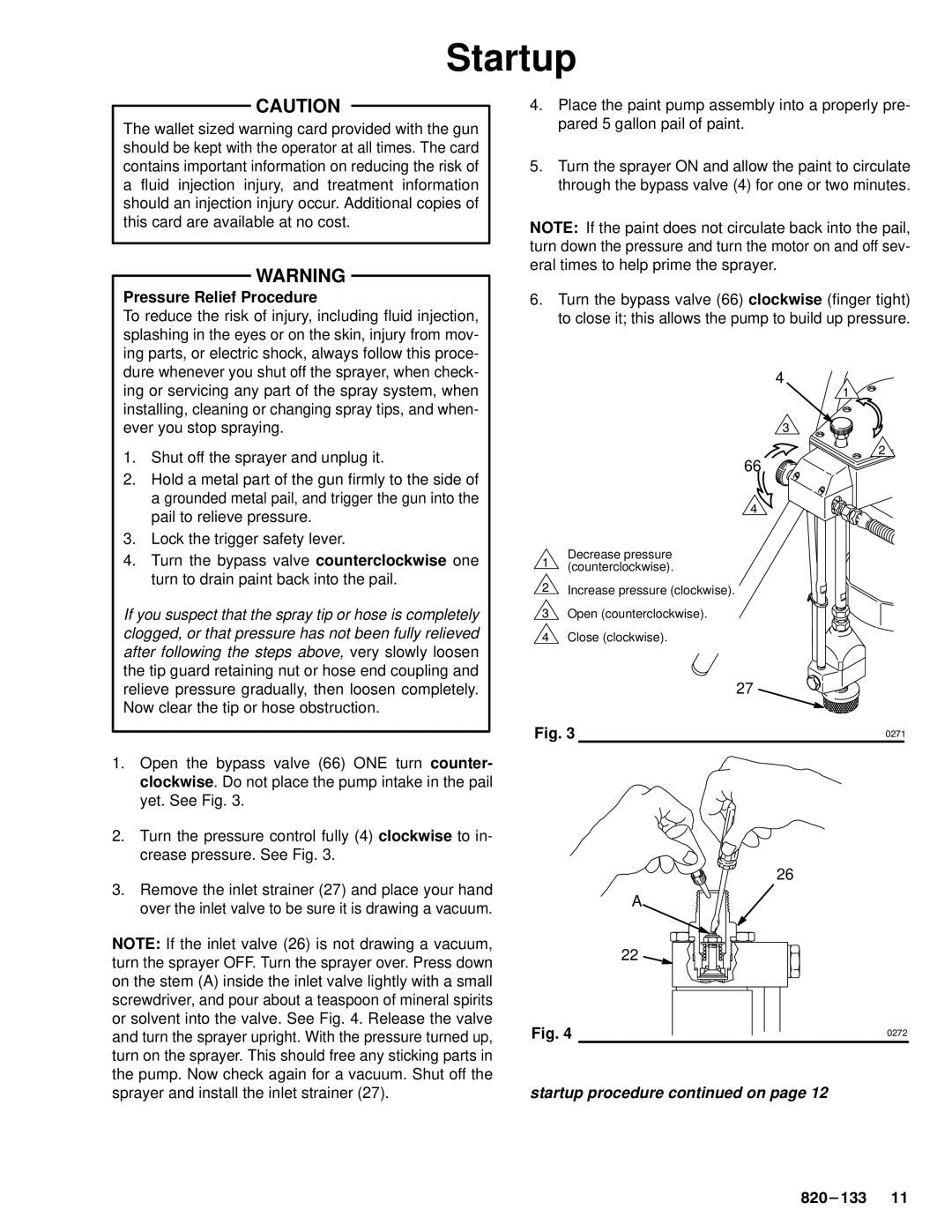

Furthermore, the Graco PT2500 comes with a built-in filter that helps prevent debris from clogging the spraying nozzle, ensuring a smooth finish every time. It also includes adjustable pressure controls, enabling users to customize the spray pattern and pressure according to the specific requirements of their painting task.

In conclusion, the Graco PT2500 is a feature-rich paint sprayer that combines portability, innovative technology, and user-friendly design. Whether tackling major renovations or simple home improvement projects, this sprayer provides the reliability and performance that users expect from Graco products. With its advanced features, the PT2500 is an excellent investment for anyone looking to achieve professional-quality results in their painting endeavors.