Troubleshooting

Troubleshooting

1.

2.

Follow Pressure Relief Procedure, page 18,

before checking or repairing gun.

Check all possible problems and causes before

disassembling gun.

CAUTION

To prevent

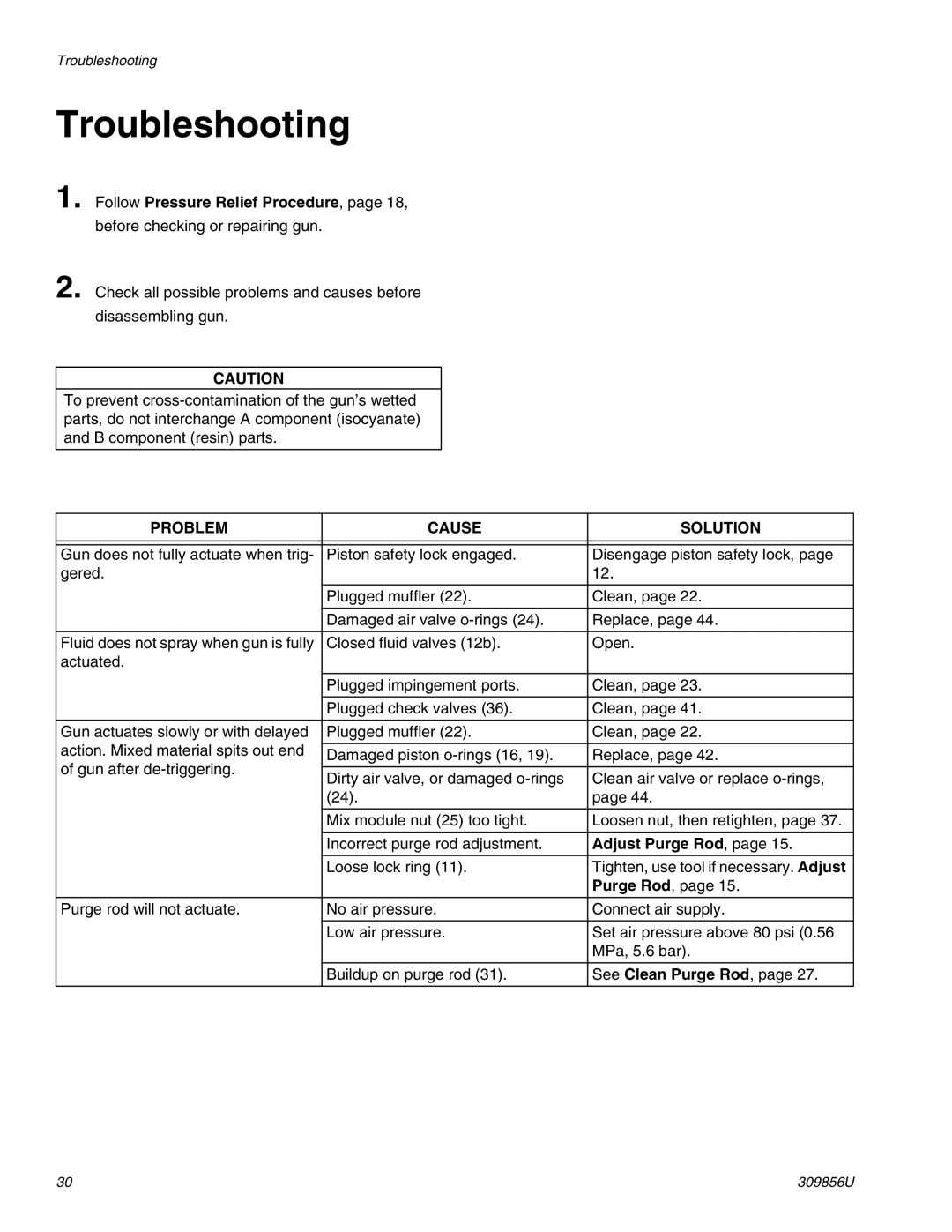

PROBLEM | CAUSE | SOLUTION | |

|

|

| |

|

|

| |

Gun does not fully actuate when trig- | Piston safety lock engaged. | Disengage piston safety lock, page | |

gered. |

| 12. | |

|

|

| |

| Plugged muffler (22). | Clean, page 22. | |

|

|

| |

| Damaged air valve | Replace, page 44. | |

|

|

| |

Fluid does not spray when gun is fully | Closed fluid valves (12b). | Open. | |

actuated. |

|

| |

|

|

| |

| Plugged impingement ports. | Clean, page 23. | |

|

|

| |

| Plugged check valves (36). | Clean, page 41. | |

|

|

| |

Gun actuates slowly or with delayed | Plugged muffler (22). | Clean, page 22. | |

action. Mixed material spits out end |

|

| |

Damaged piston | Replace, page 42. | ||

of gun after | |||

|

| ||

Dirty air valve, or damaged | Clean air valve or replace | ||

| |||

| (24). | page 44. | |

|

|

| |

| Mix module nut (25) too tight. | Loosen nut, then retighten, page 37. | |

|

|

| |

| Incorrect purge rod adjustment. | Adjust Purge Rod, page 15. | |

|

|

| |

| Loose lock ring (11). | Tighten, use tool if necessary. Adjust | |

|

| Purge Rod, page 15. | |

|

|

| |

Purge rod will not actuate. | No air pressure. | Connect air supply. | |

|

|

| |

| Low air pressure. | Set air pressure above 80 psi (0.56 | |

|

| MPa, 5.6 bar). | |

|

|

| |

| Buildup on purge rod (31). | See Clean Purge Rod, page 27. | |

|

|

|

30 | 309856U |