Troubleshooting

Problem | Cause | Solution |

|

|

|

Fluid outlet pressure gauges split | Not fully loading one side on | Increase feed pressure on side that |

only at the top changeover (if one | upstroke. | dropped. |

gauge drops, the others will rise). |

| Increase feed hose size. |

|

| |

|

| Clean inlet strainer or hopper screen. |

|

|

|

| Air mixed in fluid from excessive agi- | Flush and add new fluid. |

| tation or circulation. |

|

|

|

|

Pump Troubleshooting

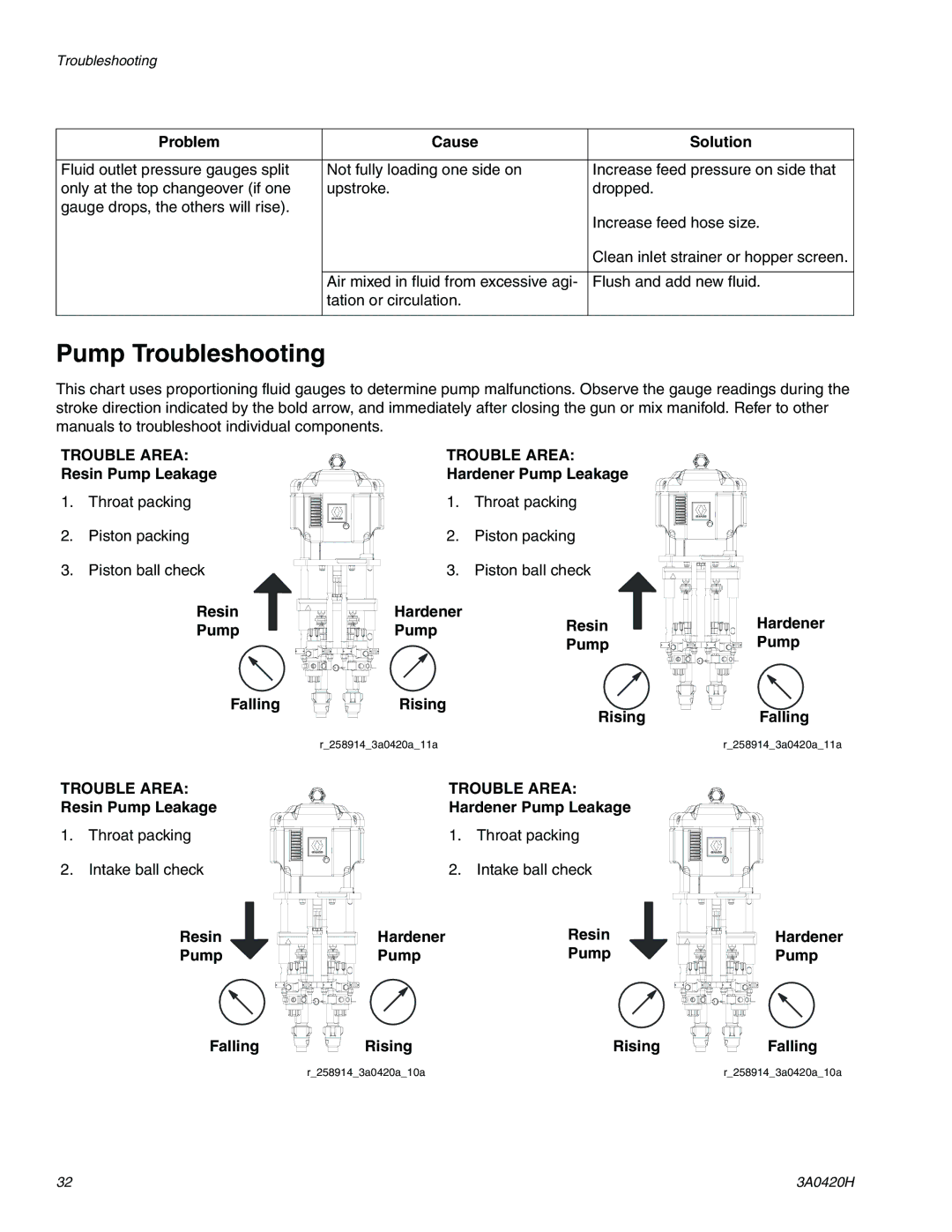

This chart uses proportioning fluid gauges to determine pump malfunctions. Observe the gauge readings during the stroke direction indicated by the bold arrow, and immediately after closing the gun or mix manifold. Refer to other manuals to troubleshoot individual components.

TROUBLE AREA: | TROUBLE AREA: | ||

Resin Pump Leakage | Hardener Pump Leakage | ||

1. | Throat packing | 1. | Throat packing |

2. | Piston packing | 2. | Piston packing |

3. | Piston ball check | 3. | Piston ball check |

| Resin | Hardener | Resin |

| Pump | Pump | |

| Pump | ||

|

|

| |

| Falling | Rising |

|

Rising

Hardener Pump

Falling

TROUBLE AREA: Resin Pump Leakage

1.Throat packing

2.Intake ball check

Resin

Pump

r_258914_3a0420a_11a

TROUBLE AREA:

Hardener Pump Leakage

1.Throat packing

2.Intake ball check

Hardener | Resin |

Pump | Pump |

r_258914_3a0420a_11a

Hardener

Pump

Falling | Rising | Rising | Falling |

| r_258914_3a0420a_10a |

| r_258914_3a0420a_10a |

32 | 3A0420H |