Important

Changing Materials

•Changing material types used in your sprayer requires special attention to avoid equipment dam- age and downtime.

•Always clean the fluid inlet strainers after flushing.

•When changing between epoxies and urethanes or polyureas, disassemble and clean all fluid compo- nents and changes hose sets.

•Check with your material manufacturer for chemical compatibility.

•Most materials use ISO on the A side, but some use ISO on the B side.

•Epoxies often have amines on the B (hardener) side. Polyureas often have amines on the B (resin) side.

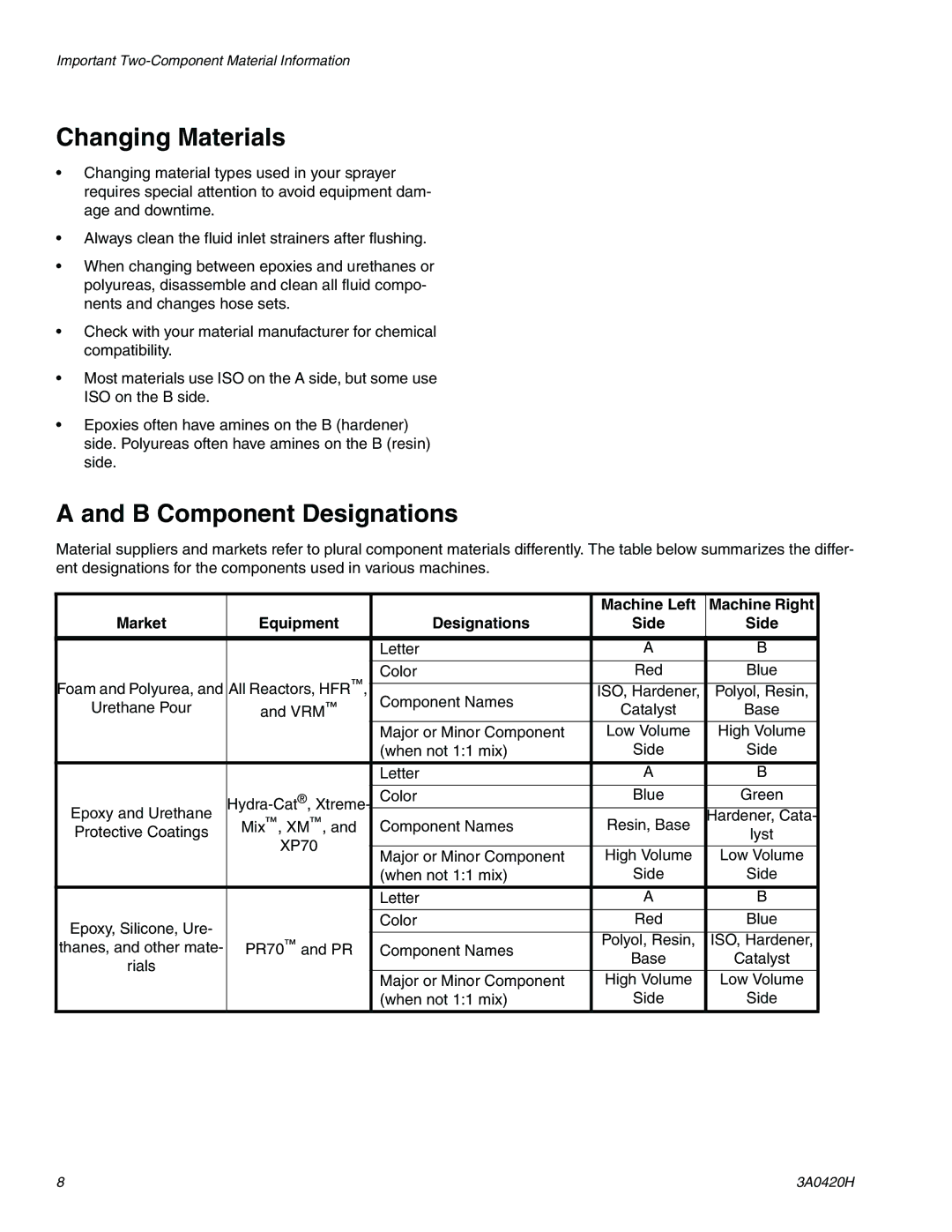

A and B Component Designations

Material suppliers and markets refer to plural component materials differently. The table below summarizes the differ- ent designations for the components used in various machines.

|

|

| Machine Left | Machine Right | |

Market | Equipment | Designations | Side | Side | |

|

|

|

|

| |

|

| Letter | A | B | |

|

|

|

|

| |

Foam and Polyurea, and | All Reactors, HFR™, | Color | Red | Blue | |

|

|

| |||

Component Names | ISO, Hardener, | Polyol, Resin, | |||

Urethane Pour | and VRM™ | Catalyst | Base | ||

| |||||

|

| Major or Minor Component | Low Volume | High Volume | |

|

| (when not 1:1 mix) | Side | Side | |

|

| Letter | A | B | |

|

|

|

|

| |

| Color | Blue | Green | ||

Epoxy and Urethane |

|

| |||

|

| Hardener, Cata- | |||

Mix™, XM™, and | Component Names | Resin, Base | |||

Protective Coatings | lyst | ||||

XP70 |

|

| |||

|

|

|

| ||

| Major or Minor Component | High Volume | Low Volume | ||

|

| ||||

|

| (when not 1:1 mix) | Side | Side | |

|

| Letter | A | B | |

|

|

|

|

| |

Epoxy, Silicone, Ure- |

| Color | Red | Blue | |

|

|

|

| ||

PR70™ and PR |

| Polyol, Resin, | ISO, Hardener, | ||

thanes, and other mate- | Component Names | ||||

Base | Catalyst | ||||

rials |

|

| |||

|

|

|

| ||

| Major or Minor Component | High Volume | Low Volume | ||

|

| ||||

|

| (when not 1:1 mix) | Side | Side | |

|

|

|

|

|

8 | 3A0420H |