|

|

|

|

|

|

| Technical Data |

Technical Data |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

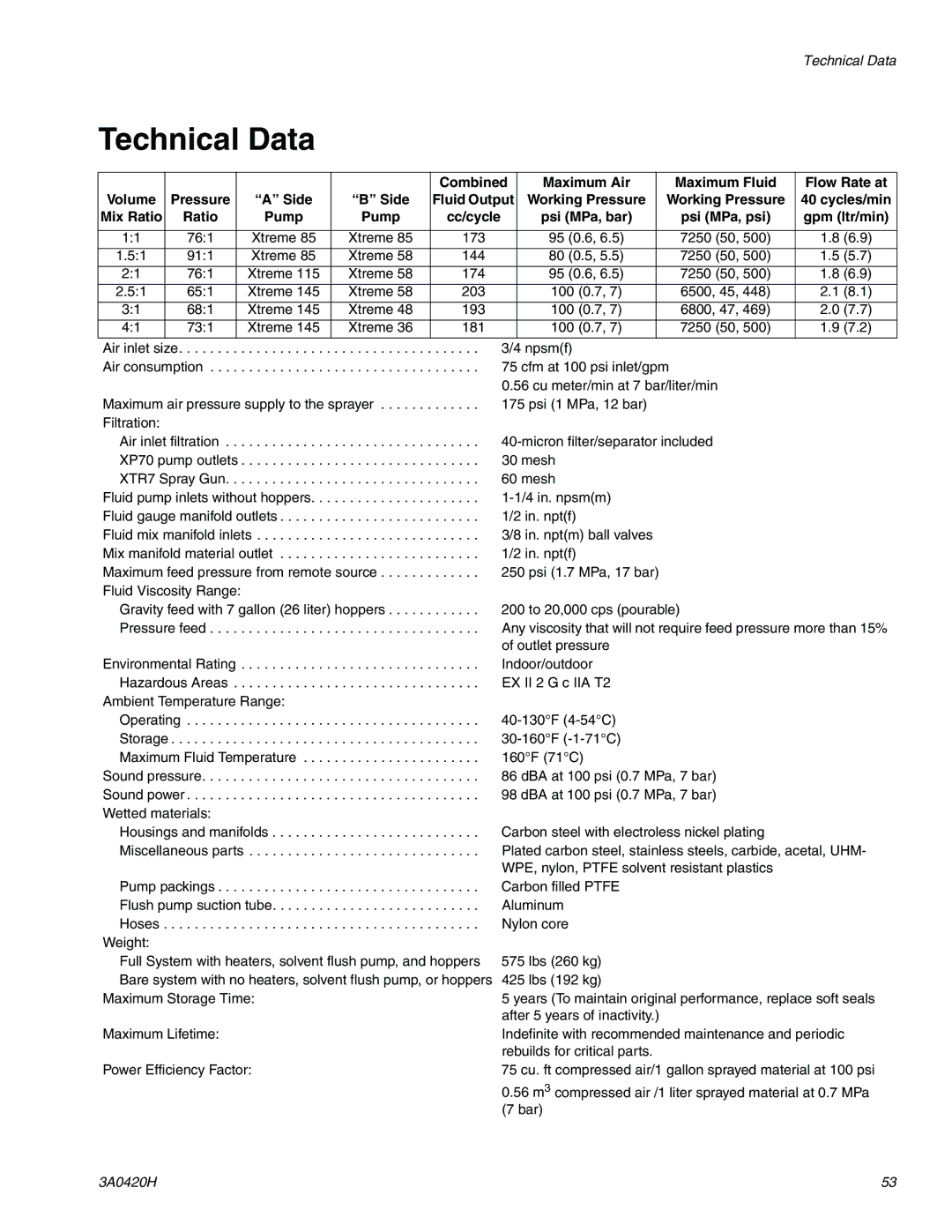

| Combined | Maximum Air | Maximum Fluid | Flow Rate at |

Volume | Pressure | “A” Side | “B” Side | Fluid Output | Working Pressure | Working Pressure | 40 cycles/min |

Mix Ratio | Ratio | Pump | Pump | cc/cycle | psi (MPa, bar) | psi (MPa, psi) | gpm (ltr/min) |

|

|

|

|

|

|

|

|

1:1 | 76:1 | Xtreme 85 | Xtreme 85 | 173 | 95 (0.6, 6.5) | 7250 (50, 500) | 1.8 (6.9) |

1.5:1 | 91:1 | Xtreme 85 | Xtreme 58 | 144 | 80 (0.5, 5.5) | 7250 (50, 500) | 1.5 (5.7) |

2:1 | 76:1 | Xtreme 115 | Xtreme 58 | 174 | 95 (0.6, 6.5) | 7250 (50, 500) | 1.8 (6.9) |

2.5:1 | 65:1 | Xtreme 145 | Xtreme 58 | 203 | 100 (0.7, 7) | 6500, 45, 448) | 2.1 (8.1) |

3:1 | 68:1 | Xtreme 145 | Xtreme 48 | 193 | 100 (0.7, 7) | 6800, 47, 469) | 2.0 (7.7) |

4:1 | 73:1 | Xtreme 145 | Xtreme 36 | 181 | 100 (0.7, 7) | 7250 (50, 500) | 1.9 (7.2) |

Air inlet size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum air pressure supply to the sprayer . . . . . . . . . . . . .

Filtration:

Air inlet filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XP70 pump outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XTR7 Spray Gun. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid pump inlets without hoppers. . . . . . . . . . . . . . . . . . . . . .

Fluid gauge manifold outlets . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid mix manifold inlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mix manifold material outlet . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum feed pressure from remote source . . . . . . . . . . . . .

Fluid Viscosity Range:

Gravity feed with 7 gallon (26 liter) hoppers . . . . . . . . . . . .

Pressure feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hazardous Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient Temperature Range:

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Fluid Temperature . . . . . . . . . . . . . . . . . . . . . . .

Sound pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted materials:

Housings and manifolds . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump packings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flush pump suction tube. . . . . . . . . . . . . . . . . . . . . . . . . . .

Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight:

Full System with heaters, solvent flush pump, and hoppers Bare system with no heaters, solvent flush pump, or hoppers

Maximum Storage Time:

Maximum Lifetime:

Power Efficiency Factor:

3/4 npsm(f)

75 cfm at 100 psi inlet/gpm

0.56cu meter/min at 7 bar/liter/min 175 psi (1 MPa, 12 bar)

30mesh

60mesh

3/8 in. npt(m) ball valves 1/2 in. npt(f)

250psi (1.7 MPa, 17 bar)

200 to 20,000 cps (pourable)

Any viscosity that will not require feed pressure more than 15% of outlet pressure

Indoor/outdoor EX II 2 G c IIA T2

86 dBA at 100 psi (0.7 MPa, 7 bar)

98 dBA at 100 psi (0.7 MPa, 7 bar)

Carbon steel with electroless nickel plating

Plated carbon steel, stainless steels, carbide, acetal, UHM- WPE, nylon, PTFE solvent resistant plastics

Carbon filled PTFE Aluminum

Nylon core

575 lbs (260 kg)

425 lbs (192 kg)

5 years (To maintain original performance, replace soft seals after 5 years of inactivity.)

Indefinite with recommended maintenance and periodic rebuilds for critical parts.

75 cu. ft compressed air/1 gallon sprayed material at 100 psi

0.56m3 compressed air /1 liter sprayed material at 0.7 MPa (7 bar)

3A0420H | 53 |