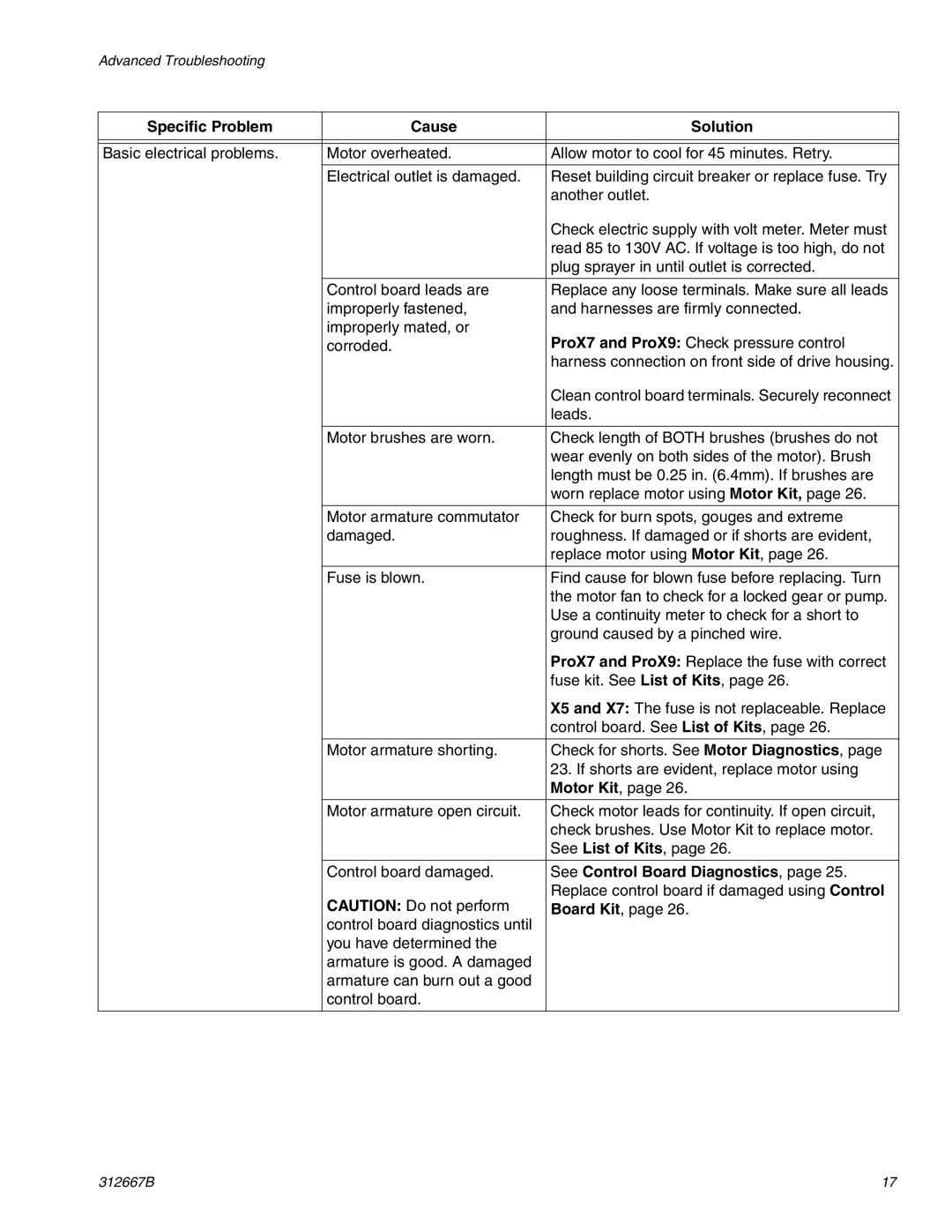

Advanced Troubleshooting

Specific Problem | Cause | Solution |

|

|

|

|

|

|

Basic electrical problems. | Motor overheated. | Allow motor to cool for 45 minutes. Retry. |

|

|

|

| Electrical outlet is damaged. | Reset building circuit breaker or replace fuse. Try |

|

| another outlet. |

|

| Check electric supply with volt meter. Meter must |

|

| read 85 to 130V AC. If voltage is too high, do not |

|

| plug sprayer in until outlet is corrected. |

|

|

|

| Control board leads are | Replace any loose terminals. Make sure all leads |

| improperly fastened, | and harnesses are firmly connected. |

| improperly mated, or | ProX7 and ProX9: Check pressure control |

| corroded. | |

|

| harness connection on front side of drive housing. |

|

| Clean control board terminals. Securely reconnect |

|

| leads. |

|

|

|

| Motor brushes are worn. | Check length of BOTH brushes (brushes do not |

|

| wear evenly on both sides of the motor). Brush |

|

| length must be 0.25 in. (6.4mm). If brushes are |

|

| worn replace motor using Motor Kit, page 26. |

|

|

|

| Motor armature commutator | Check for burn spots, gouges and extreme |

| damaged. | roughness. If damaged or if shorts are evident, |

|

| replace motor using Motor Kit, page 26. |

|

|

|

| Fuse is blown. | Find cause for blown fuse before replacing. Turn |

|

| the motor fan to check for a locked gear or pump. |

|

| Use a continuity meter to check for a short to |

|

| ground caused by a pinched wire. |

|

| ProX7 and ProX9: Replace the fuse with correct |

|

| fuse kit. See List of Kits, page 26. |

|

| X5 and X7: The fuse is not replaceable. Replace |

|

| control board. See List of Kits, page 26. |

|

|

|

| Motor armature shorting. | Check for shorts. See Motor Diagnostics, page |

|

| 23. If shorts are evident, replace motor using |

|

| Motor Kit, page 26. |

|

|

|

| Motor armature open circuit. | Check motor leads for continuity. If open circuit, |

|

| check brushes. Use Motor Kit to replace motor. |

|

| See List of Kits, page 26. |

|

|

|

| Control board damaged. | See Control Board Diagnostics, page 25. |

| CAUTION: Do not perform | Replace control board if damaged using Control |

| Board Kit, page 26. | |

| control board diagnostics until |

|

| you have determined the |

|

| armature is good. A damaged |

|

| armature can burn out a good |

|

| control board. |

|

|

|

|

312667B | 17 |