800-700, 308-530, 800-698, 800-699 specifications

Graco Inc is a renowned manufacturer specializing in fluid handling systems used in a variety of applications, particularly in industries such as construction, automotive, and manufacturing. Among their extensive product lineup, models 800-699, 800-698, 308-530, and 800-700 stand out for their innovative features and advanced technologies.The Graco 800-699 is a versatile air-operated double diaphragm pump designed for high efficiency and reliable performance. Its robust construction includes a corrosion-resistant housing ideal for handling tough fluids. The pump can effectively operate at various pressures, making it suitable for tasks ranging from transferring chemicals to applying coatings. With its easy maintenance design, operators can quickly access key components, minimizing downtime.

Model 800-698 shares similar attributes but is distinguished by its emphasis on portability and ergonomic design. This pump model is lightweight and features a compact form factor, allowing easier transport and setup for mobile applications. Its intuitive controls enable precise flow rate adjustments, giving operators enhanced control over their fluid-handling tasks. Additionally, it is designed for compatibility with a wide range of fluids, enhancing its versatility across different applications.

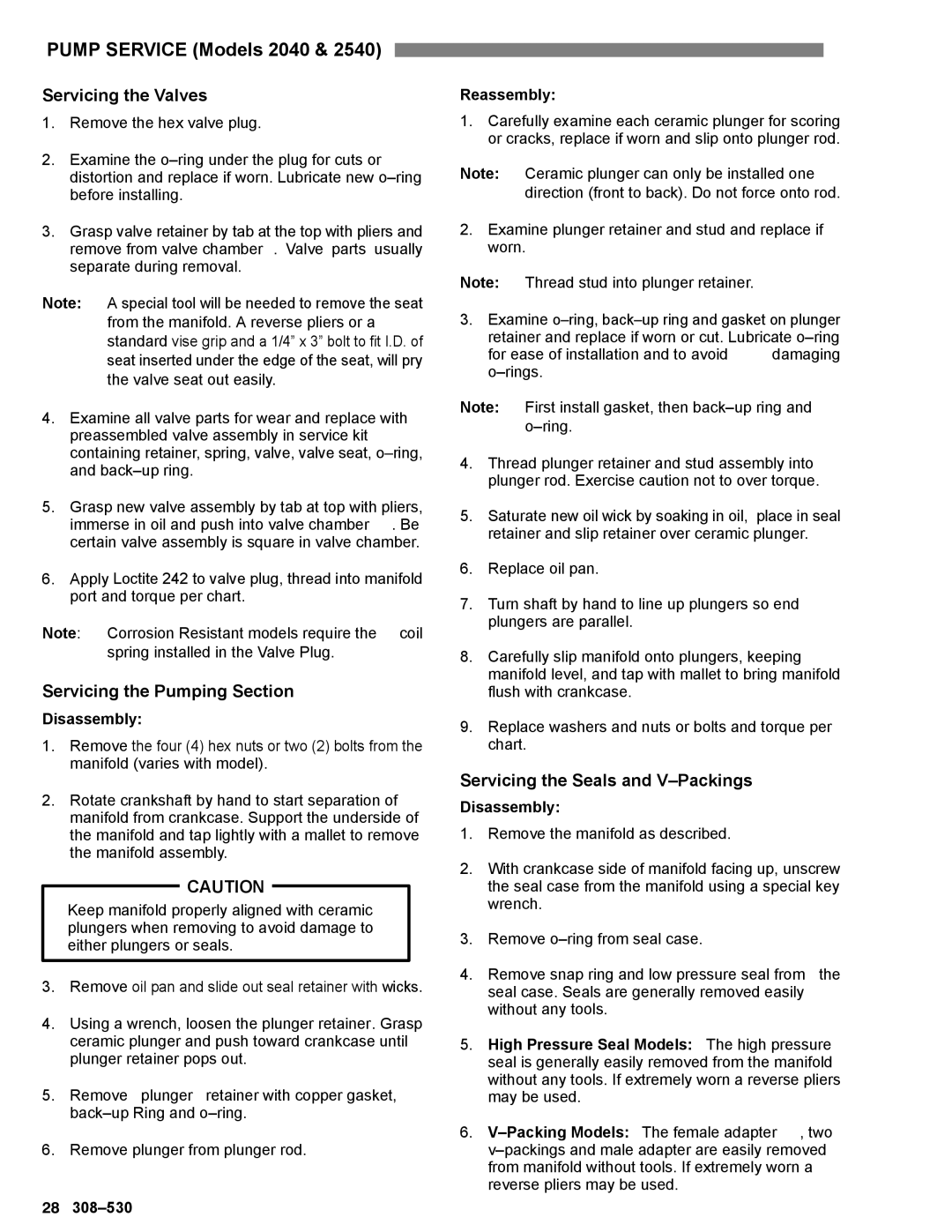

The 308-530 model is notable for its electric-driven technology. This feature makes it ideal for environments where compressed air is not available or where a quieter operation is required. The 308-530 is equipped with advanced control systems that optimize energy consumption without compromising performance. Moreover, its integrated safety features ensure reliable operation while protecting both the equipment and the operator.

Finally, the Graco 800-700 represents the pinnacle of efficiency in fluid transfer systems. This model utilizes state-of-the-art technology to provide faster flow rates and improved material compatibility. The 800-700 is engineered to handle a wide range of viscous materials, making it perfect for heavy-duty applications. The modular design allows for easy upgrades, ensuring users can keep pace with emerging technologies without extensive disruptions to their operations.

Collectively, these Graco models embody a commitment to quality, durability, and user-friendly design, allowing companies to streamline their processes and enhance productivity in fluid handling tasks. With ongoing advancements and a focus on customer satisfaction, Graco Inc continues to be a leader in this industry.