TROUBLESHOOTING

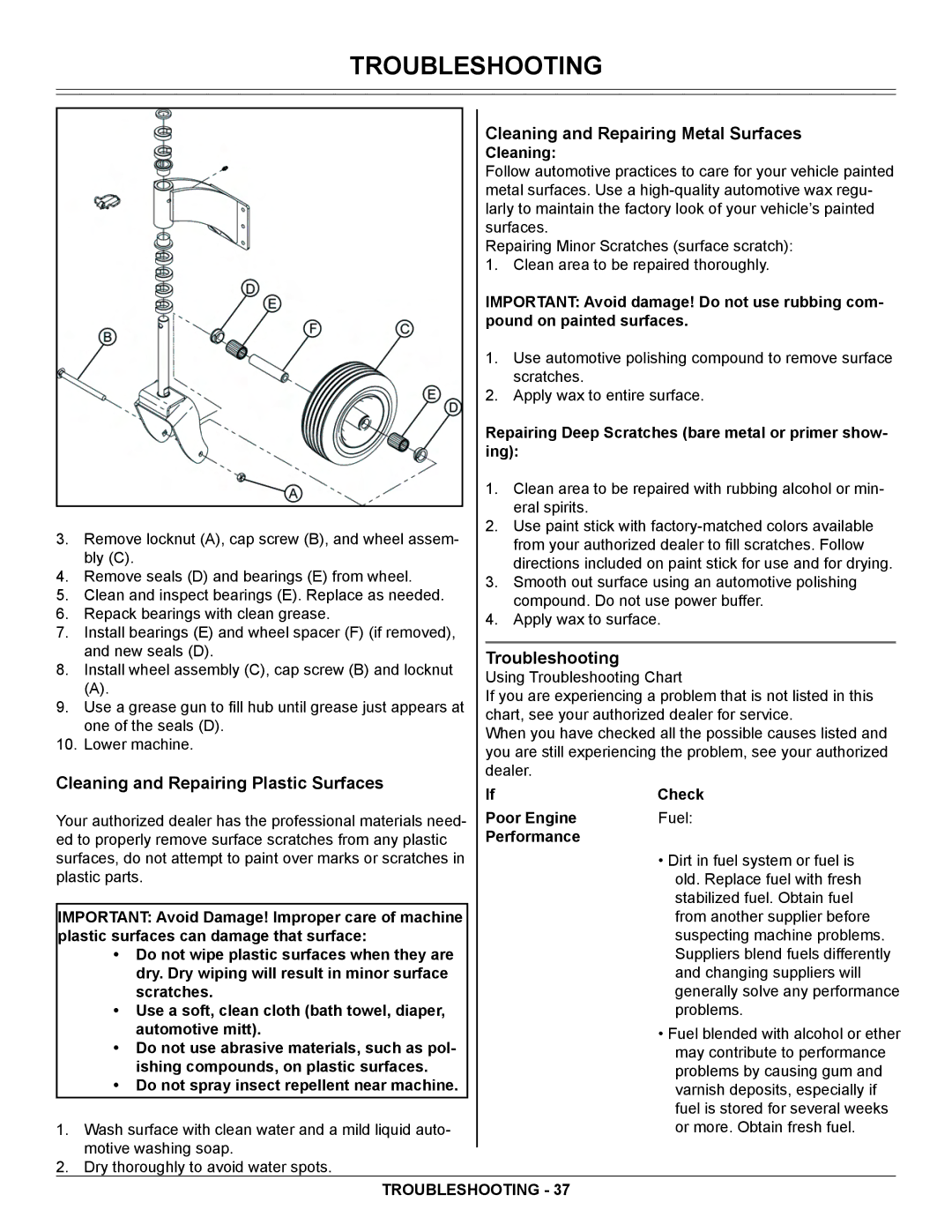

3.Remove locknut (A), cap screw (B), and wheel assem- bly (C).

4.Remove seals (D) and bearings (E) from wheel.

5.Clean and inspect bearings (E). Replace as needed.

6.Repack bearings with clean grease.

7.Install bearings (E) and wheel spacer (F) (if removed), and new seals (D).

8.Install wheel assembly (C), cap screw (B) and locknut

(A).

9.Use a grease gun to fill hub until grease just appears at one of the seals (D).

10.Lower machine.

Cleaning and Repairing Plastic Surfaces

Your authorized dealer has the professional materials need- ed to properly remove surface scratches from any plastic surfaces, do not attempt to paint over marks or scratches in plastic parts.

IMPORTANT: Avoid Damage! Improper care of machine plastic surfaces can damage that surface:

•Do not wipe plastic surfaces when they are dry. Dry wiping will result in minor surface scratches.

•Use a soft, clean cloth (bath towel, diaper, automotive mitt).

•Do not use abrasive materials, such as pol- ishing compounds, on plastic surfaces.

•Do not spray insect repellent near machine.

1.Wash surface with clean water and a mild liquid auto- motive washing soap.

2.Dry thoroughly to avoid water spots.

Cleaning and Repairing Metal Surfaces

Cleaning:

Follow automotive practices to care for your vehicle painted metal surfaces. Use a

Repairing Minor Scratches (surface scratch):

1. Clean area to be repaired thoroughly.

IMPORTANT: Avoid damage! Do not use rubbing com- pound on painted surfaces.

1.Use automotive polishing compound to remove surface scratches.

2.Apply wax to entire surface.

Repairing Deep Scratches (bare metal or primer show- ing):

1.Clean area to be repaired with rubbing alcohol or min- eral spirits.

2.Use paint stick with

3.Smooth out surface using an automotive polishing compound. Do not use power buffer.

4.Apply wax to surface.

Troubleshooting

Using Troubleshooting Chart

If you are experiencing a problem that is not listed in this chart, see your authorized dealer for service.

When you have checked all the possible causes listed and you are still experiencing the problem, see your authorized dealer.

If | Check |

Poor Engine | Fuel: |

Performance |

|

| • Dirt in fuel system or fuel is |

| old. Replace fuel with fresh |

| stabilized fuel. Obtain fuel |

| from another supplier before |

| suspecting machine problems. |

| Suppliers blend fuels differently |

| and changing suppliers will |

| generally solve any performance |

| problems. |

| • Fuel blended with alcohol or ether |

| may contribute to performance |

| problems by causing gum and |

| varnish deposits, especially if |

| fuel is stored for several weeks |

| or more. Obtain fresh fuel. |

TROUBLESHOOTING - 37