OPERATING

����� | ������ |

������� | ������� |

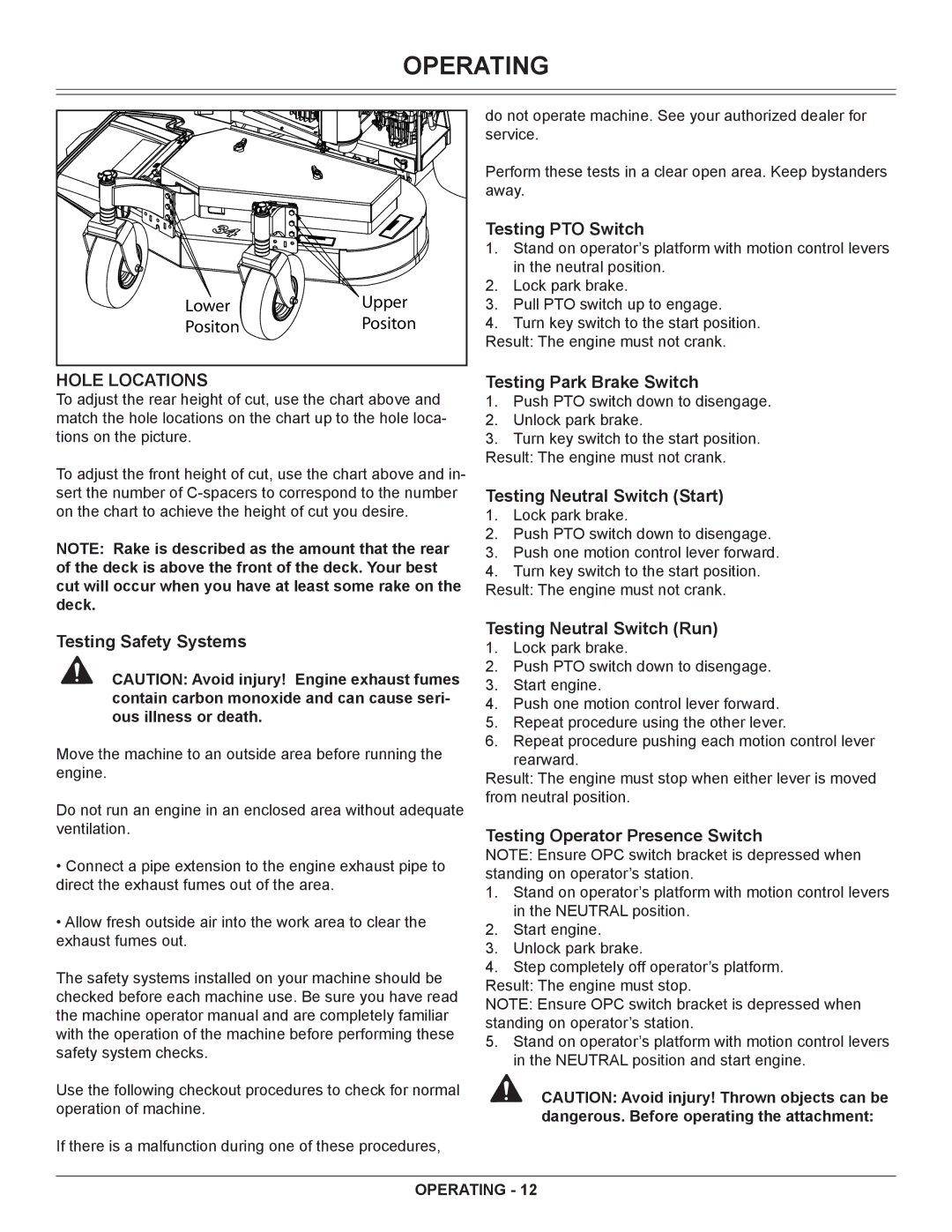

HOLE LOCATIONS

To adjust the rear height of cut, use the chart above and match the hole locations on the chart up to the hole loca- tions on the picture.

To adjust the front height of cut, use the chart above and in- sert the number of

NOTE: Rake is described as the amount that the rear of the deck is above the front of the deck. Your best cut will occur when you have at least some rake on the deck.

do not operate machine. See your authorized dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing PTO Switch

1.Stand on operator’s platform with motion control levers in the neutral position.

2.Lock park brake.

3.Pull PTO switch up to engage.

4.Turn key switch to the start position.

Result: The engine must not crank.

Testing Park Brake Switch

1.Push PTO switch down to disengage.

2.Unlock park brake.

3.Turn key switch to the start position. Result: The engine must not crank.

Testing Neutral Switch (Start)

1.Lock park brake.

2.Push PTO switch down to disengage.

3.Push one motion control lever forward.

4.Turn key switch to the start position. Result: The engine must not crank.

Testing Safety Systems

CAUTION: Avoid injury! Engine exhaust fumes contain carbon monoxide and can cause seri- ous illness or death.

Move the machine to an outside area before running the engine.

Do not run an engine in an enclosed area without adequate ventilation.

•Connect a pipe extension to the engine exhaust pipe to direct the exhaust fumes out of the area.

•Allow fresh outside air into the work area to clear the exhaust fumes out.

The safety systems installed on your machine should be checked before each machine use. Be sure you have read the machine operator manual and are completely familiar with the operation of the machine before performing these safety system checks.

Use the following checkout procedures to check for normal operation of machine.

If there is a malfunction during one of these procedures,

Testing Neutral Switch (Run)

1.Lock park brake.

2.Push PTO switch down to disengage.

3.Start engine.

4.Push one motion control lever forward.

5.Repeat procedure using the other lever.

6.Repeat procedure pushing each motion control lever rearward.

Result: The engine must stop when either lever is moved from neutral position.

Testing Operator Presence Switch

NOTE: Ensure OPC switch bracket is depressed when standing on operator’s station.

1.Stand on operator’s platform with motion control levers in the NEUTRAL position.

2.Start engine.

3.Unlock park brake.

4.Step completely off operator’s platform.

Result: The engine must stop.

NOTE: Ensure OPC switch bracket is depressed when standing on operator’s station.

5.Stand on operator’s platform with motion control levers in the NEUTRAL position and start engine.

CAUTION: Avoid injury! Thrown objects can be dangerous. Before operating the attachment:

OPERATING - 12