Maintenance

Greenheck recommends these procedures to insure trouble free operation of this unit. Most unit failures can be attributed to poor setup or poor maintenance.

A record of maintenance performed on this unit should be kept. This information will provide essential information if problems are encountered. A section at the back of this manual is provided for recording the unit's maintenance history.

CAUTION: When performing any maintenance on this unit be sure that the power is disconnected and cannot be accidently turned on. The control center disconnect can be locked in the off position .

2 weeks after startup

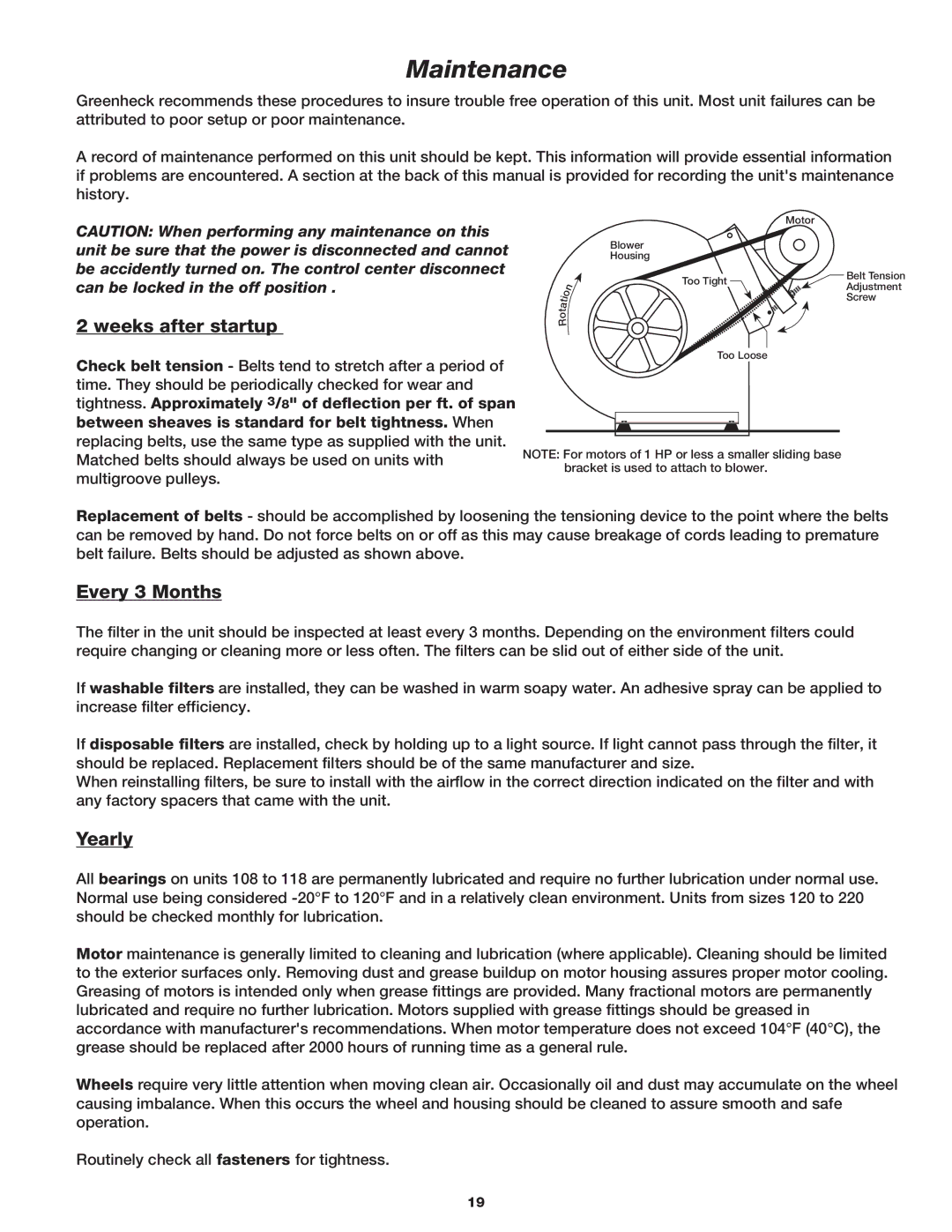

Check belt tension - Belts tend to stretch after a period of

on i t a t o R

| Motor | |

Blower |

| |

Housing |

| |

Too Tight | Belt Tension | |

Adjustment | ||

| ||

| Screw | |

Too Loose |

|

time. They should be periodically checked for wear and tightness. Approximately 3/8" of deflection per ft. of span between sheaves is standard for belt tightness. When replacing belts, use the same type as supplied with the unit. Matched belts should always be used on units with multigroove pulleys.

NOTE: For motors of 1 HP or less a smaller sliding base bracket is used to attach to blower.

Replacement of belts - should be accomplished by loosening the tensioning device to the point where the belts can be removed by hand. Do not force belts on or off as this may cause breakage of cords leading to premature belt failure. Belts should be adjusted as shown above.

Every 3 Months

The filter in the unit should be inspected at least every 3 months. Depending on the environment filters could require changing or cleaning more or less often. The filters can be slid out of either side of the unit.

If washable filters are installed, they can be washed in warm soapy water. An adhesive spray can be applied to increase filter efficiency.

If disposable filters are installed, check by holding up to a light source. If light cannot pass through the filter, it should be replaced. Replacement filters should be of the same manufacturer and size.

When reinstalling filters, be sure to install with the airflow in the correct direction indicated on the filter and with any factory spacers that came with the unit.

Yearly

All bearings on units 108 to 118 are permanently lubricated and require no further lubrication under normal use. Normal use being considered

Motor maintenance is generally limited to cleaning and lubrication (where applicable). Cleaning should be limited to the exterior surfaces only. Removing dust and grease buildup on motor housing assures proper motor cooling. Greasing of motors is intended only when grease fittings are provided. Many fractional motors are permanently lubricated and require no further lubrication. Motors supplied with grease fittings should be greased in accordance with manufacturer's recommendations. When motor temperature does not exceed 104°F (40°C), the grease should be replaced after 2000 hours of running time as a general rule.

Wheels require very little attention when moving clean air. Occasionally oil and dust may accumulate on the wheel causing imbalance. When this occurs the wheel and housing should be cleaned to assure smooth and safe operation.

Routinely check all fasteners for tightness.

19