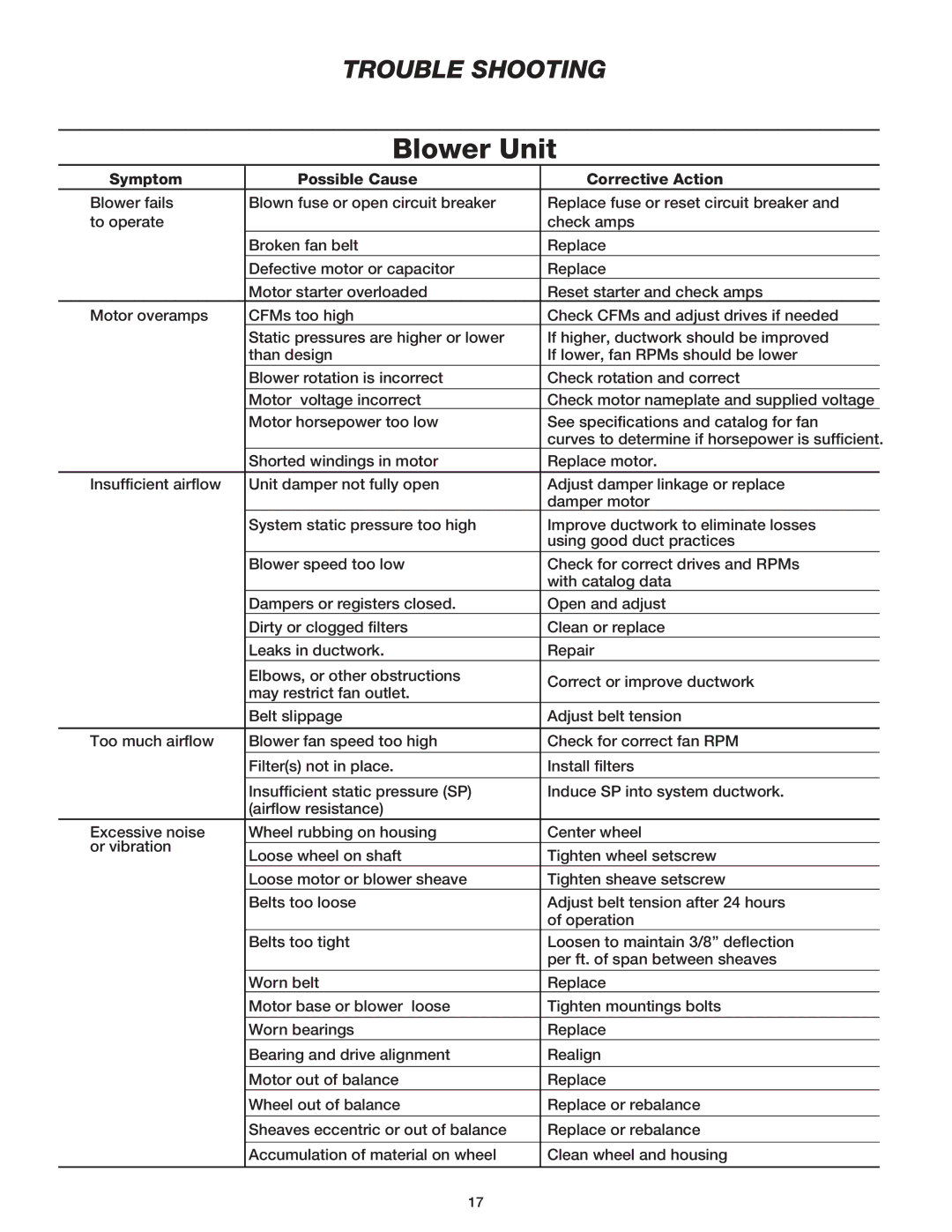

TROUBLE SHOOTING

Blower Unit

Symptom | Possible Cause | Corrective Action |

| |

Blower fails | Blown fuse or open circuit breaker | Replace fuse or reset circuit breaker and | ||

to operate |

| check amps |

| |

| Broken fan belt | Replace |

| |

| Defective motor or capacitor | Replace |

| |

| Motor starter overloaded | Reset starter and check amps |

| |

Motor overamps | CFMs too high | Check CFMs and adjust drives if needed |

| |

| Static pressures are higher or lower | If higher, ductwork should be improved | ||

| than design | If lower, fan RPMs should be lower |

| |

| Blower rotation is incorrect | Check rotation and correct | ||

|

|

|

| |

| Motor voltage incorrect | Check motor nameplate and supplied voltage |

| |

| Motor horsepower too low | See specifications and catalog for fan | ||

|

| curves to determine if horsepower is sufficient. | ||

| Shorted windings in motor | Replace motor. |

| |

|

|

|

| |

Insufficient airflow | Unit damper not fully open | Adjust damper linkage or replace | ||

|

| damper motor |

| |

| System static pressure too high | Improve ductwork to eliminate losses | ||

|

| using good duct practices |

| |

| Blower speed too low | Check for correct drives and RPMs | ||

|

| with catalog data |

| |

| Dampers or registers closed. | Open and adjust |

| |

| Dirty or clogged filters | Clean or replace |

| |

| Leaks in ductwork. | Repair |

| |

| Elbows, or other obstructions | Correct or improve ductwork | ||

| may restrict fan outlet. | |||

|

|

| ||

| Belt slippage | Adjust belt tension | ||

|

|

|

| |

Too much airflow | Blower fan speed too high | Check for correct fan RPM |

| |

| Filter(s) not in place. | Install filters | ||

|

|

|

| |

| Insufficient static pressure (SP) | Induce SP into system ductwork. | ||

| (airflow resistance) |

|

| |

Excessive noise | Wheel rubbing on housing | Center wheel | ||

or vibration |

|

|

| |

Loose wheel on shaft | Tighten wheel setscrew |

| ||

| ||||

| Loose motor or blower sheave | Tighten sheave setscrew |

| |

| Belts too loose | Adjust belt tension after 24 hours | ||

|

| of operation |

| |

| Belts too tight | Loosen to maintain 3/8” deflection | ||

|

| per ft. of span between sheaves |

| |

| Worn belt | Replace |

| |

| Motor base or blower loose | Tighten mountings bolts | ||

|

|

|

| |

| Worn bearings | Replace |

| |

| Bearing and drive alignment | Realign | ||

|

|

|

| |

| Motor out of balance | Replace |

| |

| Wheel out of balance | Replace or rebalance | ||

|

|

|

| |

| Sheaves eccentric or out of balance | Replace or rebalance | ||

|

|

|

| |

| Accumulation of material on wheel | Clean wheel and housing | ||

|

|

|

| |

17