Basics of Fan Selection

The first consideration in any fan selection is the amount of air to be moved and the resistance to this air movement. With specific performance and application criteria in mind, propeller fan selections typically require decisions based on the following criteria.

Belt Drive vs. Direct Drive

Belt drive fans offer the ability to adjust fan speed for system balancing if necessary. They also offer more flexibility in speeds and motor selections. In a cost comparison, belt drive fans are typically less costly than comparable size direct drive fans with low speed motors.

Direct drive fans are often preferred for jobs where maintenance access is difficult. Maintenance costs are generally lower with direct drive fans, since there are no belts or bearings to replace and no pulleys to adjust.

Larger Fans vs. Smaller Fans

In most applications, several fans may meet the specified airflow and pressure requirements. Just as larger fans tend to turn slower and generate less sound, they also tend to have higher initial costs but lower operating costs. Smaller fans, with their higher speeds, have more stable performance curves, lower initial costs, higher sound levels, and higher operating costs.

Low Sound vs. High Static Pressure

Fans selected for high static pressures run at higher speeds and produce higher tip speeds, resulting in higher sound levels. Conversely, in low pressure applications, fans generally run at lower speed producing lower sound levels and are recommended for sound sensitive applications.

How Accessories Affect Static Pressure

All accessory losses must be accounted for when calculating a fan’s static pressure load. In most cases dampers, guards and weatherhoods actually add very little to the total system pressure. This means that propeller fans used in conjunction with common accessories can typically be specified with low pressure capabilities (below 3⁄8 in. wg). However, in cases where airflow velocities exceed 1500 fpm through the damper or where filters are used, static pressure loss may be significant. For more specific information on pressure losses due to accessories, refer to pages 9 and 10.

Motor Service Factor

Motors for sidewall propeller fans are cooled by the airstream. With an uninterrupted flow of cooling air, motors may be operated in their service factor range (up to 20% above the motor’s nameplate horsepower) without damage due to overheating. Lesser overloads are recommended for applications using totally enclosed or explosion resistant motors.

Belt drive performance tables in this catalog show two speed selections for each propeller type (L or

H)at a given motor hp. The first selection is a 1.0 bhp service factor. The second speed selection is at 1.2 bhp service factor. Direct drive performance tables show BHP levels with service factors ranging up to 1.2 bhp. When a selection at 1.2 bhp service factor is not desirable for the application, specify the next higher motor horsepower.

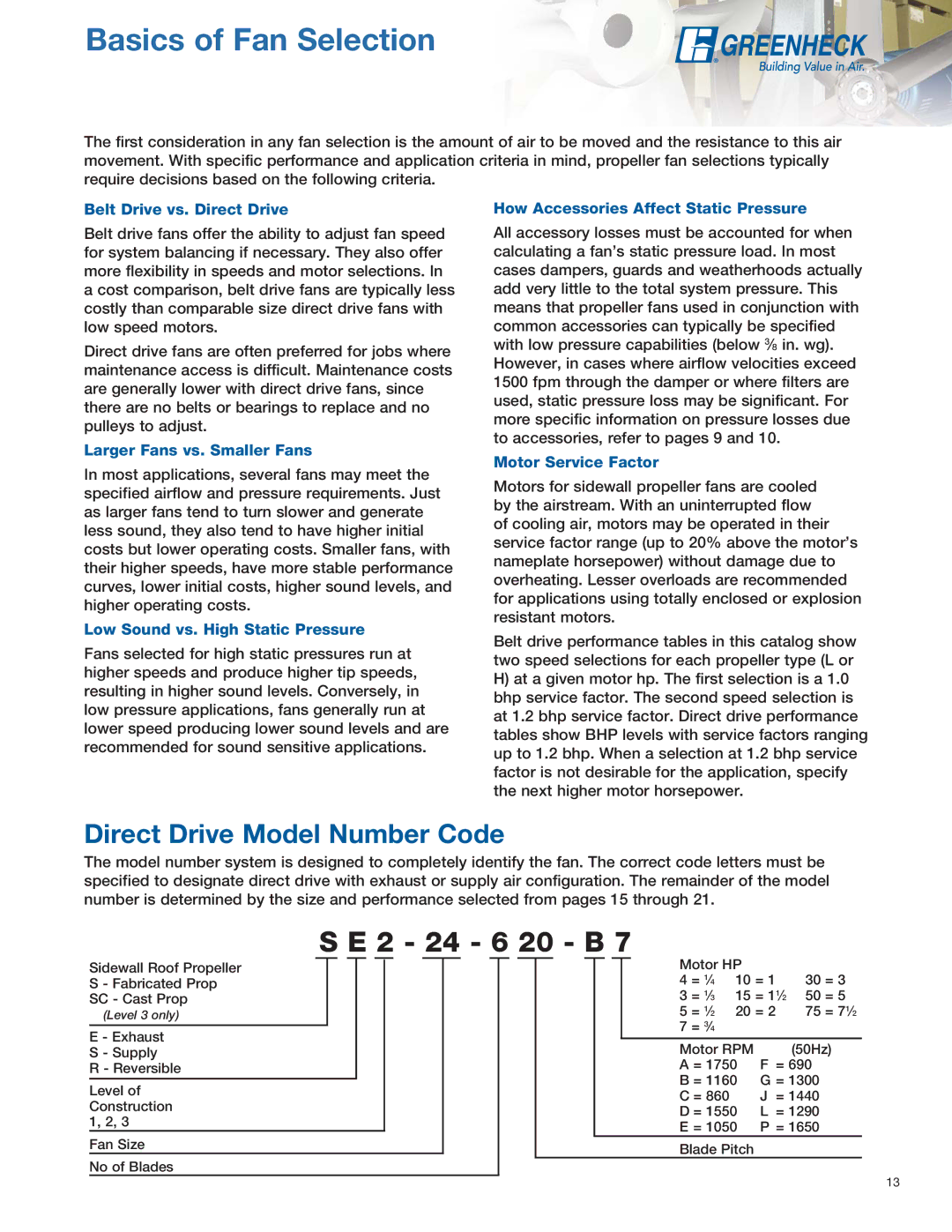

Direct Drive Model Number Code

The model number system is designed to completely identify the fan. The correct code letters must be specified to designate direct drive with exhaust or supply air configuration. The remainder of the model number is determined by the size and performance selected from pages 15 through 21.

S E 2 - 24 - 6 20 - B 7

Sidewall Roof Propeller

S - Fabricated Prop

SC - Cast Prop

(Level 3 only)

E - Exhaust

S - Supply

R - Reversible

Level of Construction 1, 2, 3

Fan Size

No of Blades

Motor HP |

| |

4 = 1⁄4 | 10 = 1 | 30 = 3 |

3 = 1⁄3 | 15 = 11⁄2 | 50 = 5 |

5 = 1⁄2 | 20 = 2 | 75 = 71⁄2 |

7 = 3⁄4 |

|

|

Motor RPM | (50Hz) |

A = 1750 | F = 690 |

B = 1160 | G = 1300 |

C = 860 | J = 1440 |

D = 1550 | L = 1290 |

E = 1050 | P = 1650 |

Blade Pitch

13