Model Comparison

Direct Drive Fan Selection

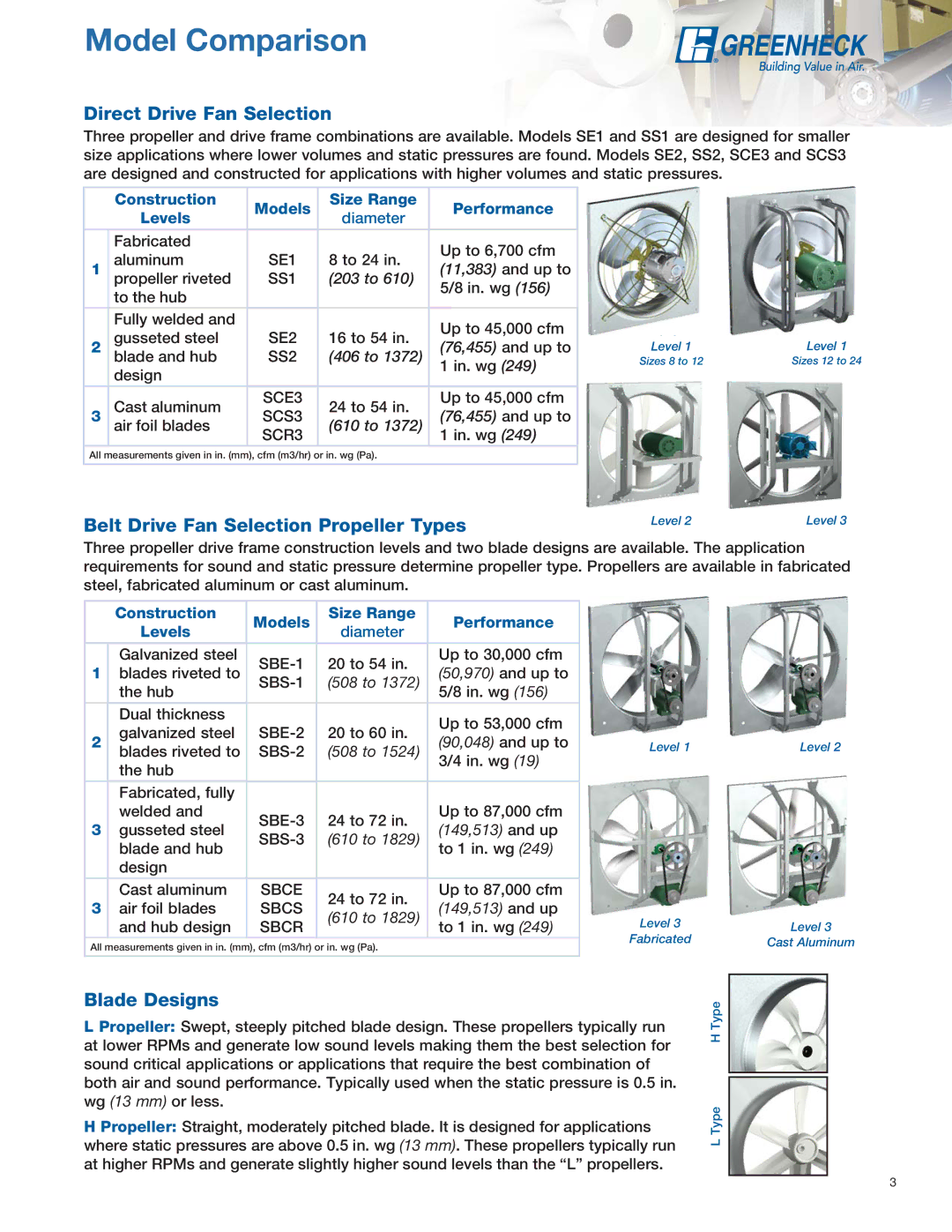

Three propeller and drive frame combinations are available. Models SE1 and SS1 are designed for smaller size applications where lower volumes and static pressures are found. Models SE2, SS2, SCE3 and SCS3 are designed and constructed for applications with higher volumes and static pressures.

| Construction | Models | Size Range | Performance |

|

| |

| Levels | diameter |

|

| |||

|

|

|

|

| |||

| Fabricated |

|

| Up to 6,700 cfm |

|

| |

| aluminum | SE1 | 8 to 24 in. |

|

| ||

1 | (11,383) and up to |

|

| ||||

propeller riveted | SS1 | (203 to 610) |

|

| |||

| to the hub |

|

| 5/8 in. wg (156) |

|

| |

|

|

|

|

|

| ||

| Fully welded and |

|

| Up to 45,000 cfm | Level 1 | Level 1 | |

| gusseted steel | SE2 | 16 to 54 in. | ||||

2 | (76,455) and up to | Sizes 8 to 12 | Sizes 12 to 24 | ||||

blade and hub | SS2 | (406 to 1372) | |||||

|

|

|

|

| Level 1 | Level 1 | |

| design |

|

| 1 in. wg (249) |

|

| |

|

|

|

|

|

| ||

| Cast aluminum | SCE3 | 24 to 54 in. | Up to 45,000 cfm |

|

| |

3 | SCS3 | (76,455) and up to |

|

| |||

| air foil blades | SCR3 | (610 to 1372) | 1 in. wg (249) |

|

| |

All measurements given in in. (mm), cfm (m3/hr) or in. wg (Pa). |

|

|

| ||||

|

|

|

|

|

|

| |

Belt Drive Fan Selection Propeller Types

Level 2 | Level 3 |

Three propeller drive frame construction levels and two blade designs are available. The application requirements for sound and static pressure determine propeller type. Propellers are available in fabricated steel, fabricated aluminum or cast aluminum.

| Construction | Models | Size Range | Performance |

| |

| Levels | diameter |

| |||

|

|

|

| |||

|

|

|

|

|

| |

| Galvanized steel | 20 to 54 in. | Up to 30,000 cfm |

| ||

1 | blades riveted to | (50,970) and up to |

| |||

(508 to 1372) |

| |||||

| the hub | 5/8 in. wg (156) |

| |||

|

|

|

| |||

| Dual thickness |

|

| Up to 53,000 cfm |

| |

| galvanized steel | 20 to 60 in. |

| |||

2 | (90,048) and up to | Level 1 | ||||

blades riveted to | (508 to 1524) | |||||

| 3/4 in. wg (19) | |||||

| the hub |

|

|

| ||

|

|

|

|

| ||

| Fabricated, fully |

|

|

|

| |

| welded and | 24 to 72 in. | Up to 87,000 cfm |

| ||

3 | gusseted steel | (149,513) and up |

| |||

(610 to 1829) |

| |||||

| blade and hub | to 1 in. wg (249) |

| |||

|

|

|

| |||

| design |

|

|

|

| |

| Cast aluminum | SBCE | 24 to 72 in. | Up to 87,000 cfm |

| |

3 | air foil blades | SBCS | (149,513) and up |

| ||

(610 to 1829) | Level 3 | |||||

| and hub design | SBCR | to 1 in. wg (249) | |||

|

| |||||

|

|

|

|

| Fabricated | |

All measurements given in in. (mm), cfm (m3/hr) or in. wg (Pa). |

| |||||

|

| |||||

|

|

|

|

|

| |

Blade Designs

L Propeller: Swept, steeply pitched blade design. These propellers typically run at lower RPMs and generate low sound levels making them the best selection for sound critical applications or applications that require the best combination of both air and sound performance. Typically used when the static pressure is 0.5 in. wg (13 mm) or less.

H Propeller: Straight, moderately pitched blade. It is designed for applications where static pressures are above 0.5 in. wg (13 mm). These propellers typically run at higher RPMs and generate slightly higher sound levels than the “L” propellers.

Level 2

Level 3

Cast Aluminum

H Type

L Type

3