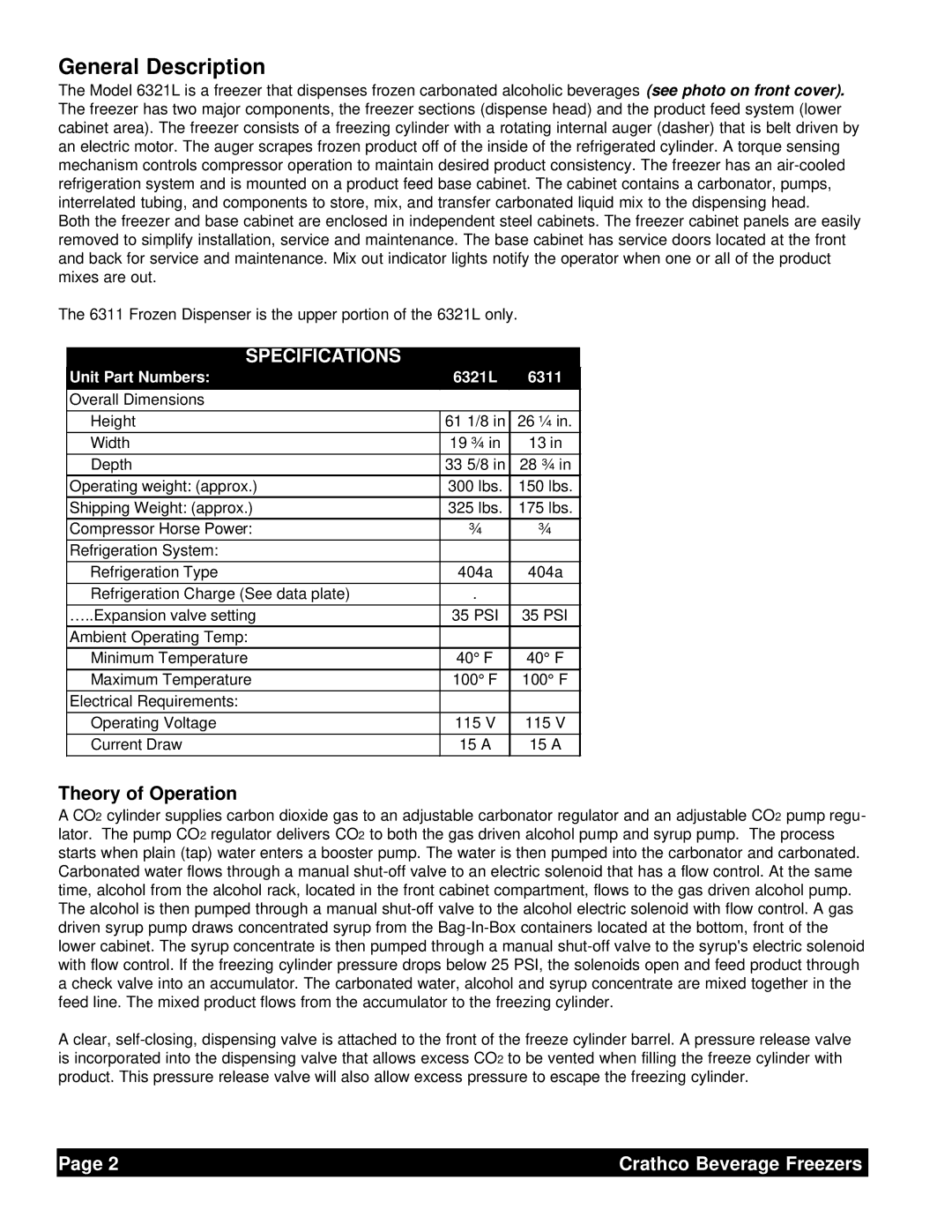

6321L specifications

The Grindmaster 6321L is an advanced commercial coffee grinder designed for coffee shops, cafes, and restaurants that demand efficiency, consistency, and superior quality in their coffee preparation process. Known for its robust design and innovative features, the Grindmaster 6321L stands out in the competitive coffee grinding market.One of the main features of the Grindmaster 6321L is its precision grinding capability. The grinder utilizes 1.5-horsepower commercial-grade motors combined with stainless steel burrs, ensuring a consistent grind size for various coffee beans. This precision is crucial for brewing high-quality coffee, as it affects the extraction and ultimately the flavor profile.

Another significant characteristic of the 6321L is its user-friendly interface. The grinder is equipped with an intuitive digital display, allowing baristas to adjust settings with ease. Users can customize grind settings to achieve their desired coarseness or fineness, catering to different brewing methods such as espresso, drip, or French press. The presets enhance operational efficiency, reducing the time spent on adjusting grind sizes during busy service hours.

The Grindmaster 6321L also features a large-capacity hopper capable of holding a significant amount of coffee beans, minimizing the need for frequent refills. This characteristic is particularly advantageous in high-volume coffee environments, ensuring uninterrupted service. Additionally, the grinder is built with a sound-dampening design, reducing noise levels during operation—a thoughtful feature for establishments focused on customer experience.

Advanced technological aspects of the Grindmaster 6321L include its grind-on-demand system which ensures that coffee beans are only ground when needed. This feature preserves the freshness of the coffee, delivering an aromatic and flavorful brew every time. The grinder is also equipped with an automatic shut-off feature, enhancing energy efficiency and safety.

Durability is another key characteristic of the Grindmaster 6321L. Constructed with high-quality materials, it is designed to withstand the rigors of daily commercial use. With its solid construction and reliable performance, the 6321L is a perfect investment for any coffee business looking to elevate its coffee service.

In summary, the Grindmaster 6321L offers a blend of precision, customization, and durability. Its state-of-the-art features make it an indispensable tool for professionals in the coffee industry, ensuring that every cup served meets the highest standards of quality.