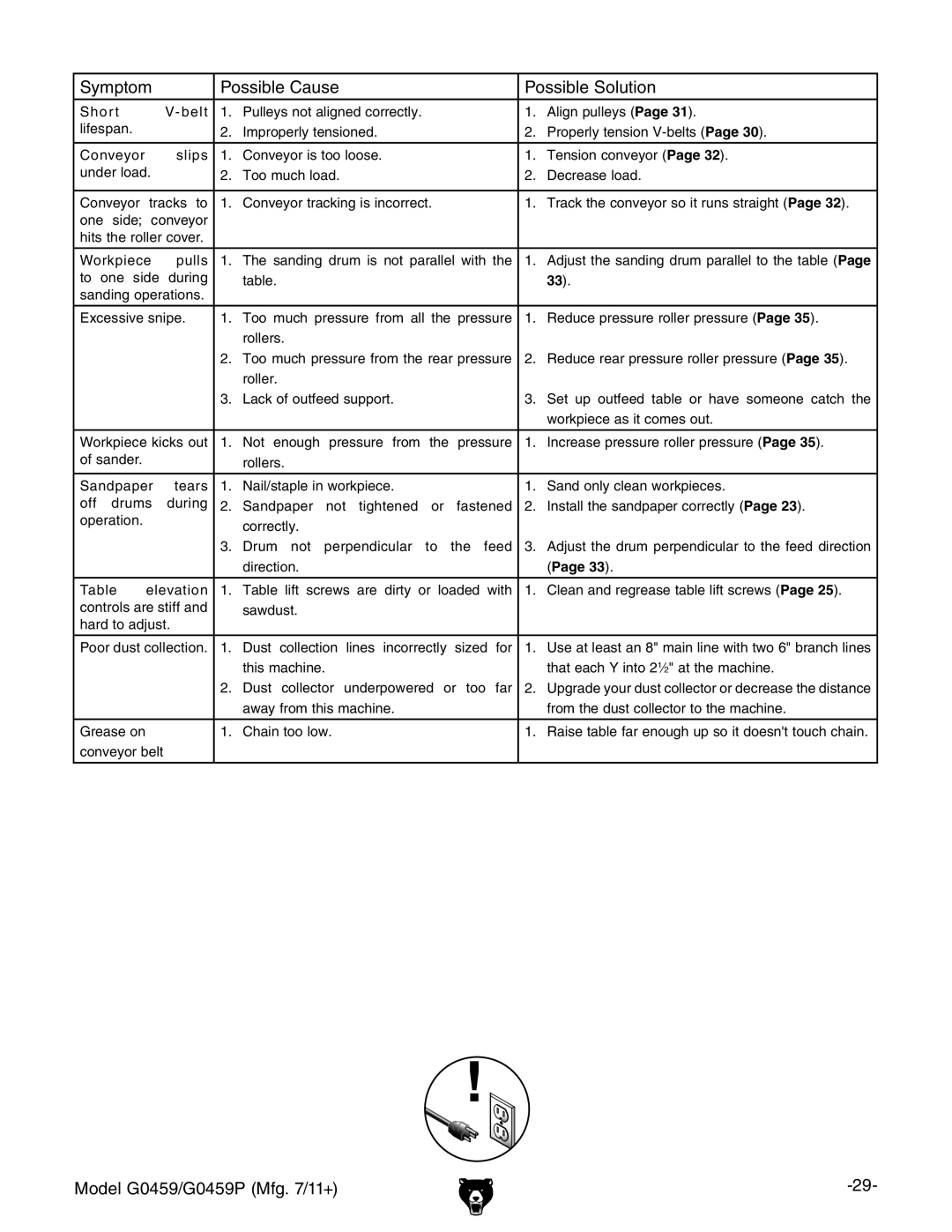

Symptom |

| Possible Cause | Possible Solution | ||||

Short |

| 1. | Pulleys not aligned correctly. | 1. | Align pulleys (Page 31). | ||

lifespan. |

|

| 2. | Improperly tensioned. | 2. | Properly tension | |

|

|

|

|

|

|

| |

Conveyor |

| slips | 1. | Conveyor is too loose. | 1. | Tension conveyor (Page 32). | |

under load. |

| 2. | Too much load. | 2. | Decrease load. | ||

|

|

|

|

|

| ||

Conveyor | tracks to | 1. | Conveyor tracking is incorrect. | 1. | Track the conveyor so it runs straight (Page 32). | ||

one side; | conveyor |

|

|

|

| ||

hits the roller cover. |

|

|

|

| |||

|

|

|

|

|

| ||

Workpiece | pulls | 1. | The sanding drum is not parallel with the | 1. | Adjust the sanding drum parallel to the table (Page | ||

to | one side | during |

| table. |

| 33). | |

sanding operations. |

|

|

|

| |||

Excessive snipe. | 1. | Too much pressure from all the pressure | 1. | Reduce pressure roller pressure (Page 35). | |||

|

|

|

|

| rollers. |

|

|

|

|

|

| 2. | Too much pressure from the rear pressure | 2. | Reduce rear pressure roller pressure (Page 35). |

|

|

|

|

| roller. |

|

|

|

|

|

| 3. | Lack of outfeed support. | 3. | Set up outfeed table or have someone catch the |

|

|

|

|

|

|

| workpiece as it comes out. |

|

|

|

|

| |||

Workpiece kicks out | 1. | Not enough pressure from the pressure | 1. | Increase pressure roller pressure (Page 35). | |||

of sander. |

|

|

| rollers. |

|

| |

|

|

|

|

|

| ||

Sandpaper | tears | 1. | Nail/staple in workpiece. | 1. | Sand only clean workpieces. | ||

off | drums | during | 2. | Sandpaper not tightened or fastened | 2. | Install the sandpaper correctly (Page 23). | |

operation. |

|

|

| correctly. |

|

| |

|

|

|

|

|

|

| |

|

|

|

| 3. | Drum not perpendicular to the feed | 3. | Adjust the drum perpendicular to the feed direction |

|

|

|

|

| direction. |

| (Page 33). |

|

|

|

|

|

| ||

Table | elevation | 1. | Table lift screws are dirty or loaded with | 1. | Clean and regrease table lift screws (Page 25). | ||

controls are stiff and |

| sawdust. |

|

| |||

hard to adjust. |

|

|

|

| |||

Poor dust collection. | 1. | Dust collection lines incorrectly sized for | 1. | Use at least an 8" main line with two 6" branch lines | |||

|

|

|

|

| this machine. |

| that each Y into 21⁄2" at the machine. |

|

|

|

| 2. | Dust collector underpowered or too far | 2. | Upgrade your dust collector or decrease the distance |

|

|

|

|

| away from this machine. |

| from the dust collector to the machine. |

|

|

|

|

|

|

| |

Grease on |

|

| 1. | Chain too low. | 1. | Raise table far enough up so it doesn't touch chain. | |

conveyor belt |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

Model G0459/G0459P (Mfg. 7/11+) |