Replacing Drive Belt

To replace and tension the drive belt:

1.Disconnect the machine from the power source!

2.Remove the drive belt cover plate.

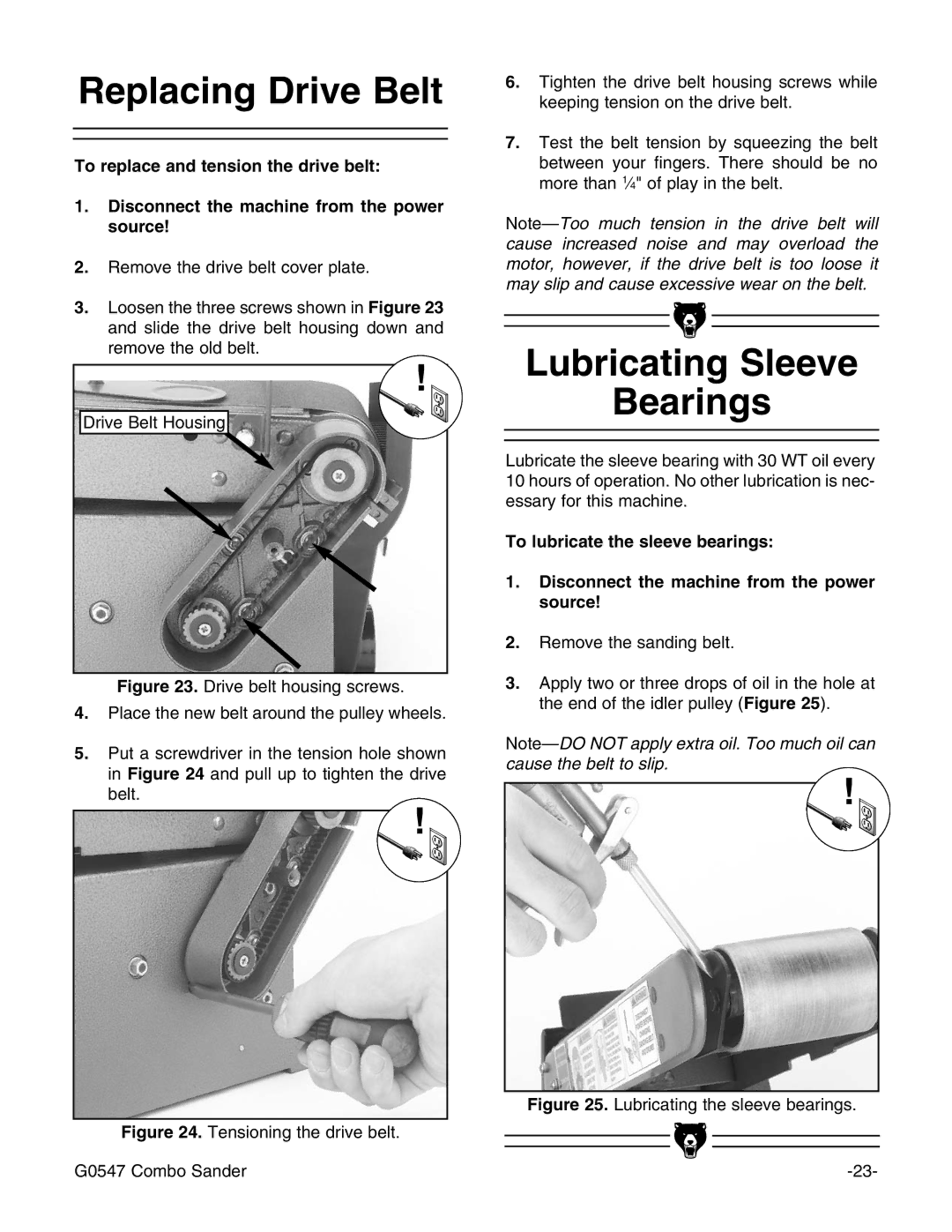

3.Loosen the three screws shown in Figure 23 and slide the drive belt housing down and remove the old belt.

! |

Drive Belt Housing |

Figure 23. Drive belt housing screws.

4.Place the new belt around the pulley wheels.

5.Put a screwdriver in the tension hole shown in Figure 24 and pull up to tighten the drive belt.

!

Figure 24. Tensioning the drive belt.

G0547 Combo Sander

6.Tighten the drive belt housing screws while keeping tension on the drive belt.

7.Test the belt tension by squeezing the belt between your fingers. There should be no more than 1⁄4" of play in the belt.

Lubricating Sleeve

Bearings

Lubricate the sleeve bearing with 30 WT oil every 10 hours of operation. No other lubrication is nec- essary for this machine.

To lubricate the sleeve bearings:

1.Disconnect the machine from the power source!

2.Remove the sanding belt.

3.Apply two or three drops of oil in the hole at the end of the idler pulley (Figure 25).

!