Disc Sanding

Always keep the workpiece on the side of the wheel that is rotating down toward the table. This will keep the workpiece from flying out of your hands from the rota- tional forces.

To perform disc sanding operations:

1.Set the angle of the table relative to the sanding disc. The angle can be set with the angle scale on the disc sander or with a pro- tractor for greater accuracy.

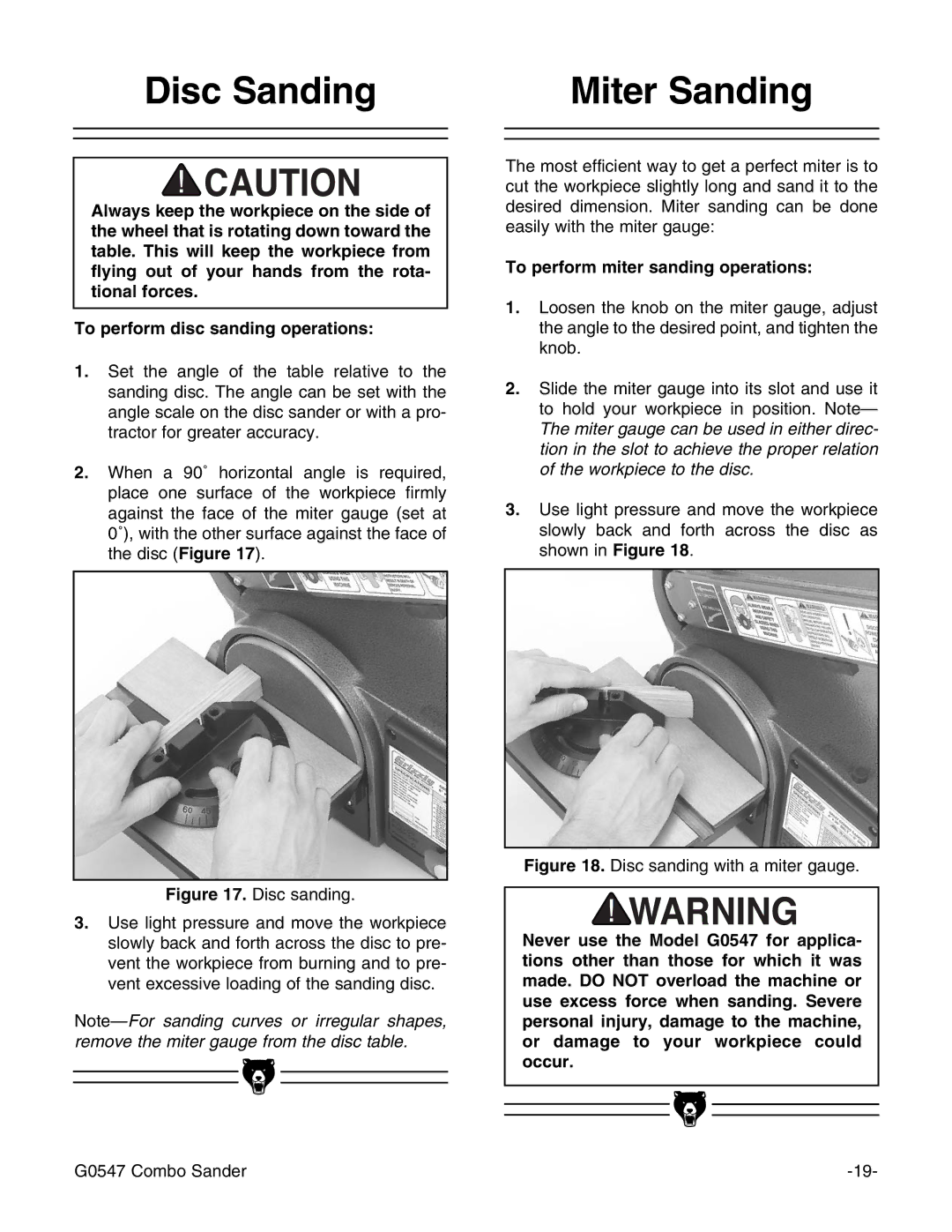

2.When a 90˚ horizontal angle is required, place one surface of the workpiece firmly against the face of the miter gauge (set at 0˚), with the other surface against the face of the disc (Figure 17).

Figure 17. Disc sanding.

3.Use light pressure and move the workpiece slowly back and forth across the disc to pre- vent the workpiece from burning and to pre- vent excessive loading of the sanding disc.

Miter Sanding

The most efficient way to get a perfect miter is to cut the workpiece slightly long and sand it to the desired dimension. Miter sanding can be done easily with the miter gauge:

To perform miter sanding operations:

1.Loosen the knob on the miter gauge, adjust the angle to the desired point, and tighten the knob.

2.Slide the miter gauge into its slot and use it to hold your workpiece in position. Note— The miter gauge can be used in either direc- tion in the slot to achieve the proper relation of the workpiece to the disc.

3.Use light pressure and move the workpiece slowly back and forth across the disc as shown in Figure 18.

Figure 18. Disc sanding with a miter gauge.

Never use the Model G0547 for applica- tions other than those for which it was made. DO NOT overload the machine or use excess force when sanding. Severe personal injury, damage to the machine, or damage to your workpiece could occur.

|

|

|

|

|

|

|

|

|

|

|

|

G0547 Combo Sander | |||